Germany-based Kühling&Kühling now offer two very powerful 3D printers suitable for professional use.

When we last saw the company, it was in 2013, when they offered a kind of “super RepRap” machine with features not commonly found on desktop 3D printers of the day. Their goal at the time with the “RepRap Industrial” was to make a machine more amenable to the needs of engineers and designers requiring more a more powerful machine.

That goal seems to still be on their minds when we examined their two current products, the HT500.2 and extremely interesting VP75 delta system.

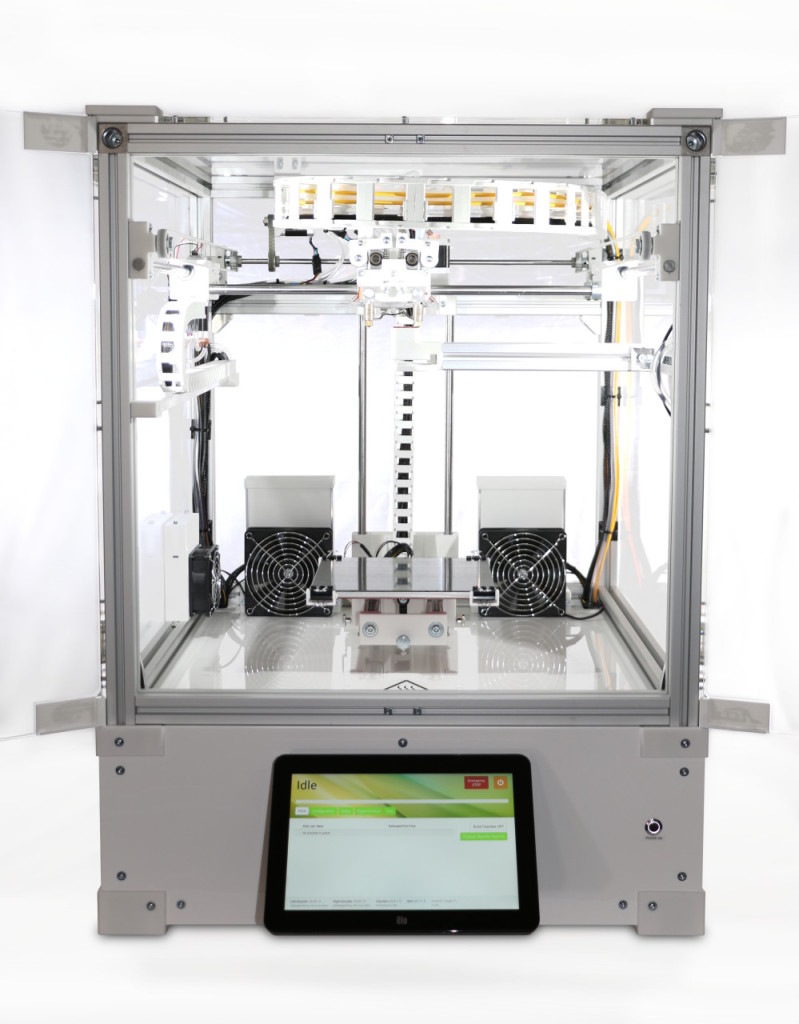

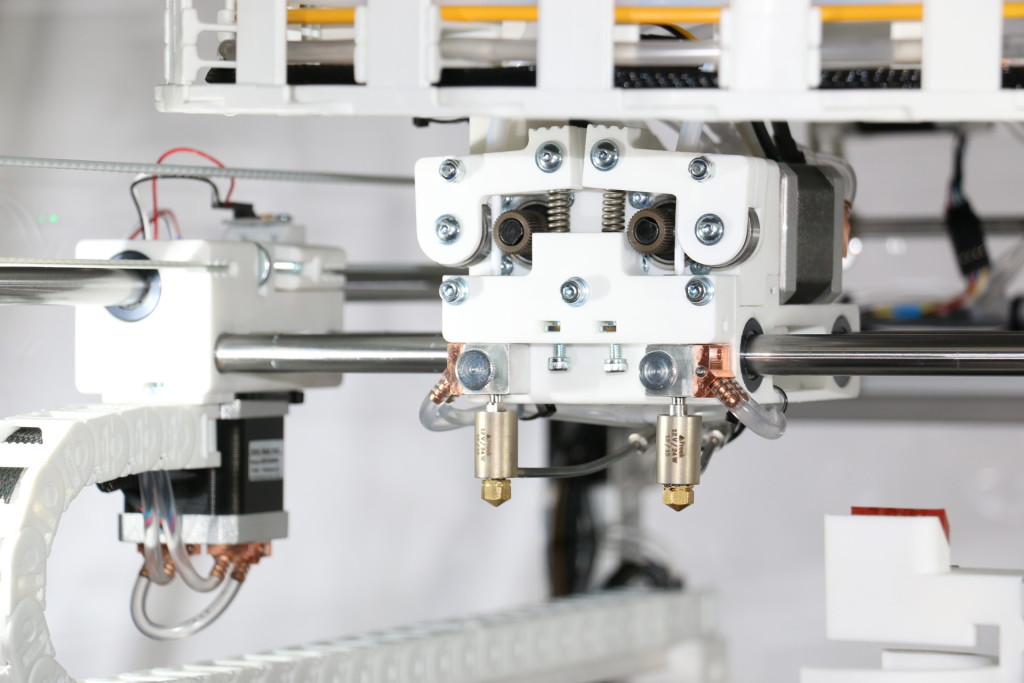

The HT500.2 is a desktop 3D printer that appears to be a new generation of equipment grown from their prior RepRap Industrial. As was the Industrial model, the HT500.2 is focused on heat and heat control, but it goes much farther. The two print heads are capable of an astonishing +500C temperatures. This is quite notable as competing “high temperature” machines typically top out at 400-450C. This means the HT500.2 is capable of 3D printing more high temperature materials than most other machines.

The build chamber is heated up to 70C, the temperature you’d find in far more expensive units, and one that virtually ensures warp free prints. Similarly, the heated print surface can hit 130C, again higher than many other machines.

To avoid problems, the company has designed the machine to house the critical electronics and mechanical components outside the heated chamber so they are not damaged by the high heats occurring in this system.

It has a fairly good build volume, too, at 200 x 180 x 290mm, and can print layers as small as 0.05mm. For larger prints you can install a large-diameter nozzle to print coarsely, but more quickly.

The HT500.2 sells for approximately €15,000 (USD$16,000).

But what’s even more interesting is an entirely new machine they’ve recently developed, the “VP75 Additive Manufacturing System”.

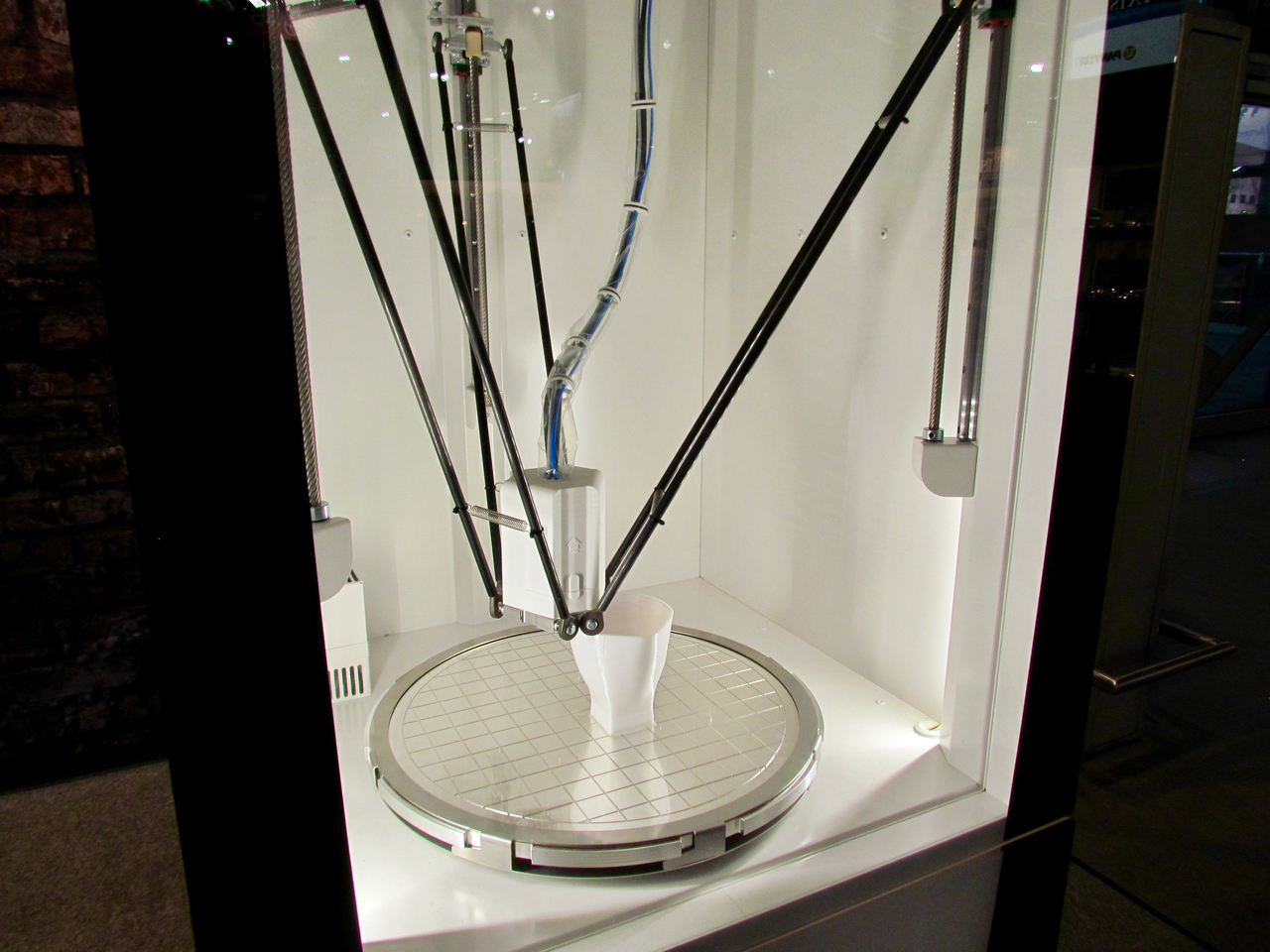

As you can tell in this image, the VP75 is a delta-style machine. But the major difference between this machine and most other deltas is that it is an enclosed system with powerful heat controls.

As with other deltas, this machine has a very large cylindrical print volume of 400mm diameter and 600mm tall, and the minimum layer size is listed at 0.05mm, the same as the HT500.2.

However, what’s more interesting is that the other specifications are similar to the HT500.2, including the 500C high temperature print head and 150C heated print surface. The build chamber can even hit 80C for unusual high temperature materials.

An interesting feature is the “VacuFlat” print surface. It seems they have developed a PEI adhesive sheet for the build surface that is vacuumed down flat on to the print platform for quick release once the print finishes. Pop in another sheet and you’re up and printing again instantly, and can remove the finished print from the PEI sheet at your leisure. However, for this feature you’ll need a supply of compressed air to operate the vacuum plate.

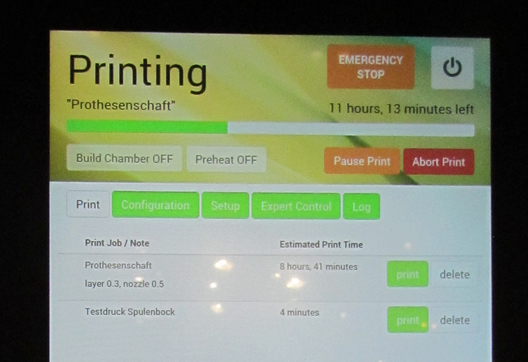

The rest of the machine is engineered for ease of use and includes a number of features, such as a large color touch screen, networking, automatic calibration and more. There’s also a 12-month warranty with extended service packages available.

And it’s a really stylish machine, too.

This machine looks so good that their partner BigRep chose to market it worldwide through their sales force.

You can pick up a VP75 for only €39,000 (USD$41,500).

Via Kühling&Kühling