EOS is well known as one of the few true industrial 3D printer manufacturers around, and we examined some of their latest upgrades.

The company has long provided equipment used behind the scenes at many popular 3D print services, usually nylon machines such as their Formiga 110, part of their “P” series (“P” stands for “Plastic”). Currently the largest machine in this series is the massive P 770, equipped with two fast-moving independent lasers for doubling the productivity of the unit.

The developments in the equipment have been a bit more subtle, but they are critically important. The company has been introducing additional sensors and controls into the system in order to achieve higher quality prints with increased reliability. This approach is really all about heat control: the more precise you can control the environment, laser power and speeds, the higher quality your result. And of course, one of their key goals is to ensure the machine is able to consistently repeat performance, job after job.

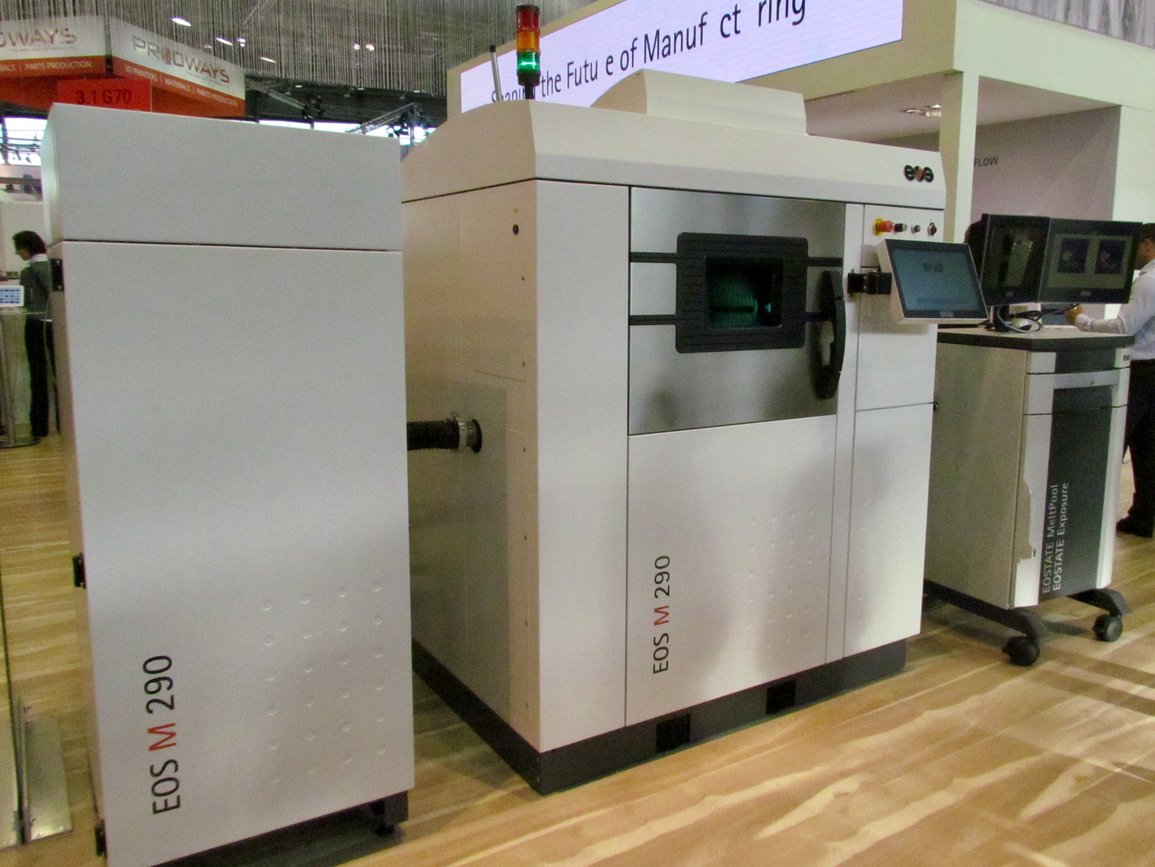

The company also has an “M” series of metal 3D printers, again one of the very few large companies doing so.

In a similar process, EOS is improving the quality of metal prints by using their EOSTATE software monitoring system. This is a single point of reference to understand the operation of the machine.

They’ve introduced a component called “EOSTATE MeltPool”, which is a way to directly monitor literally every pixel of material being fused into a part as it happens inside the EOS machine.

It does this by taking up to ten images of the print bed every second and observing the brightness of the fused and fusing powder. From this information and their experience-based algorithms, EOS can instantly detect issues where incorrectly fused sections occurred. This enables operators to restart printing without wasting expensive material and get the job done faster.

This type of monitoring might seem overkill, but it is actually quite critical for certain applications. Imagine an aircraft part 3D printed in metal. If this flight-critical part were to fail and cause an accident, subsequent investigations would surely point the finger at the poorly printed part and the method, process and equipment it was produced on.

For this reason it is essential for any 3D metal printer to provide as much monitoring as possible to ensure parts are of identical and appropriate quality for their intended use.

This technology is available for all of EOS’ metal equipment.

I should mention EOS’ biggest metal machine to date, the massive M400-4, shown here. This huge machine has a “-4” to indicate that it includes FOUR independently operating lasers that can very quickly burn a layer, making it quite fast to operate. The lasers operate in separate zones, however, so if you are 3D printing a smaller metal object that spans only one zone, it won’t be much faster.

EOS is also beginning to provide operational automation options for the metal equipment. Operating 3D metal printers is quite labor intensive as loading, unloading and powder management is all done manually.

One step they’ve taken is to develop a modular chamber system and robot that can assist in powder management. This robot is able to transport residual powder produced during a print to a sifting station where the powder is refreshed for another print job.

It appears that EOS is one of the few leading 3D printer manufacturers that is now seriously addressing the shortcomings of the technology that have up to now limited the application to industrial production. If they’re successful, we could see a lot more EOS equipment in factories of the future.

Via EOS