This week’s selection is the practical 3D printable sound absorbers by designer Julien Dorra.

Paris-based Dorra calls himself a “creative technologist”, and that’s exactly what one should be to design these sound absorbers.

Sound absorbers are essential elements in modern office and residential design. Without them, sound echoes off of hard surfaces like glass and tile, presenting an uncomfortable work and living space. Interior designers typically include an amount of “soft” surfaces like carpets, ceiling tiles and the like to innocuously absorb stray sounds.

But sometimes they don’t. And you then enjoy an unpleasant echoey experience.

To solve the problem you must purchase and install a quantity of sound absorbing sheets, which come in an extremely wide variety of shapes, styles and colors. They also come with exorbitant price tags.

Enter Dorra’s project. Here you can find parametric designs for sound absorbing elements. The idea is to 3D print combinations of them to apply to your space’s surfaces to absorb sound.

The sound absorber set includes several different styles of sound absorbing mechanisms that can apply to different audio situations. Dorra explains that these designs are “based on acoustic research litterature from 1975 up to 2016.” The techniques include:

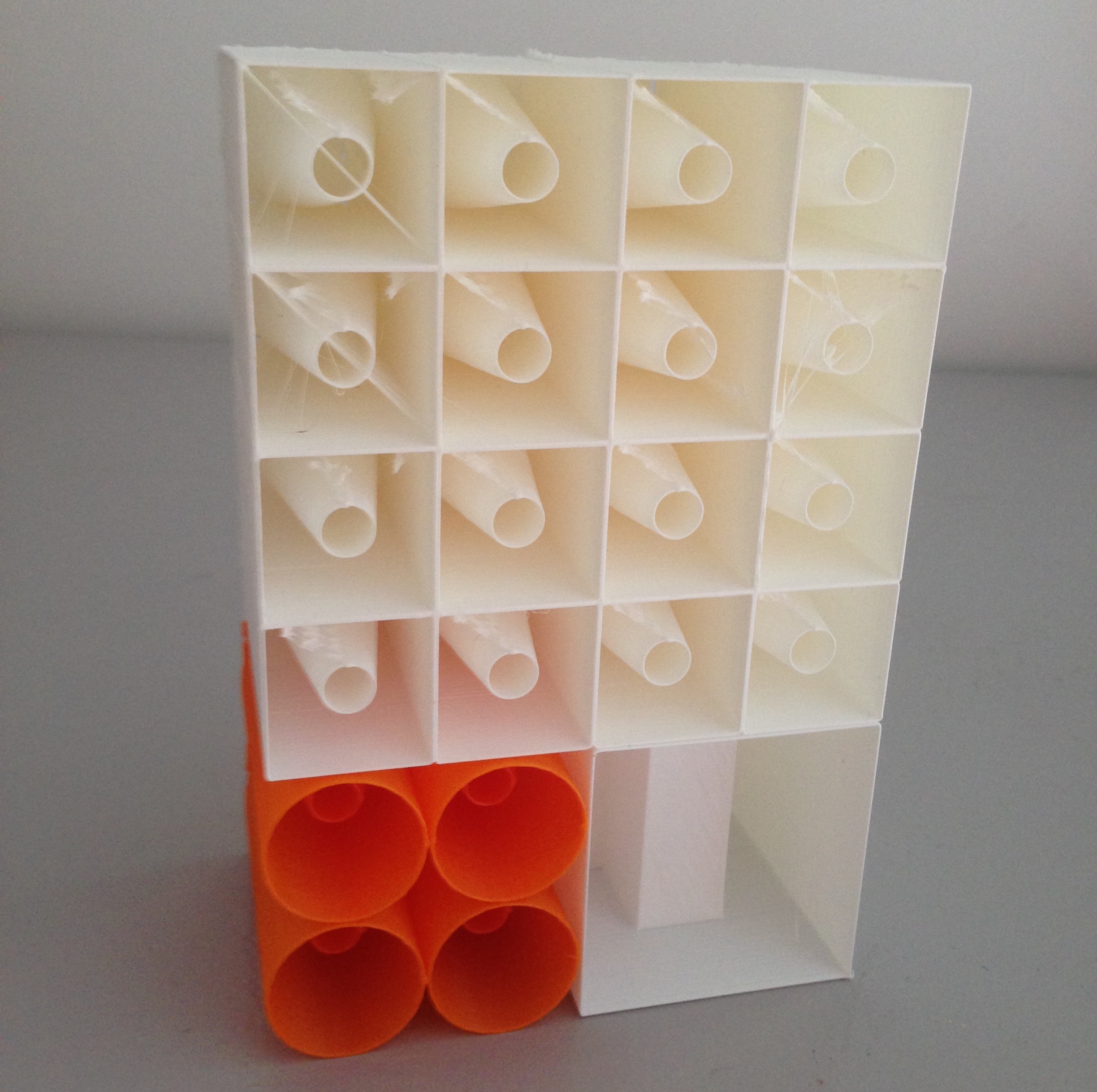

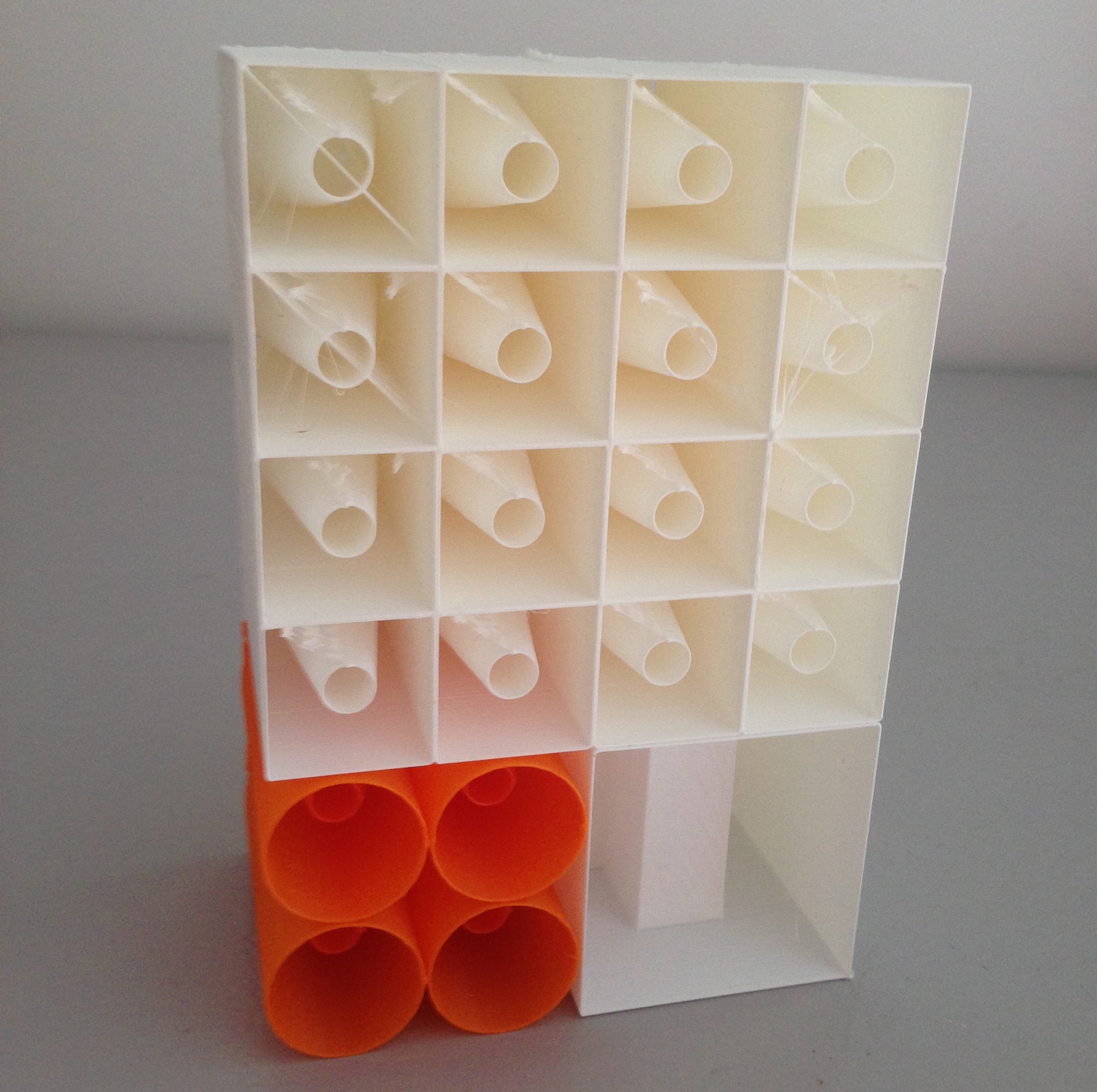

- Micro Perforated Panels with cone backing

- Micro Perforated Panels with 3-length tunnel backing

- Destructive interference – hard to tune, still quite large [not implemented]

- Perforated panels with coplanar coiled air chamber – allow low frequency absorption with very thin panels [preliminary, brittle implementation]

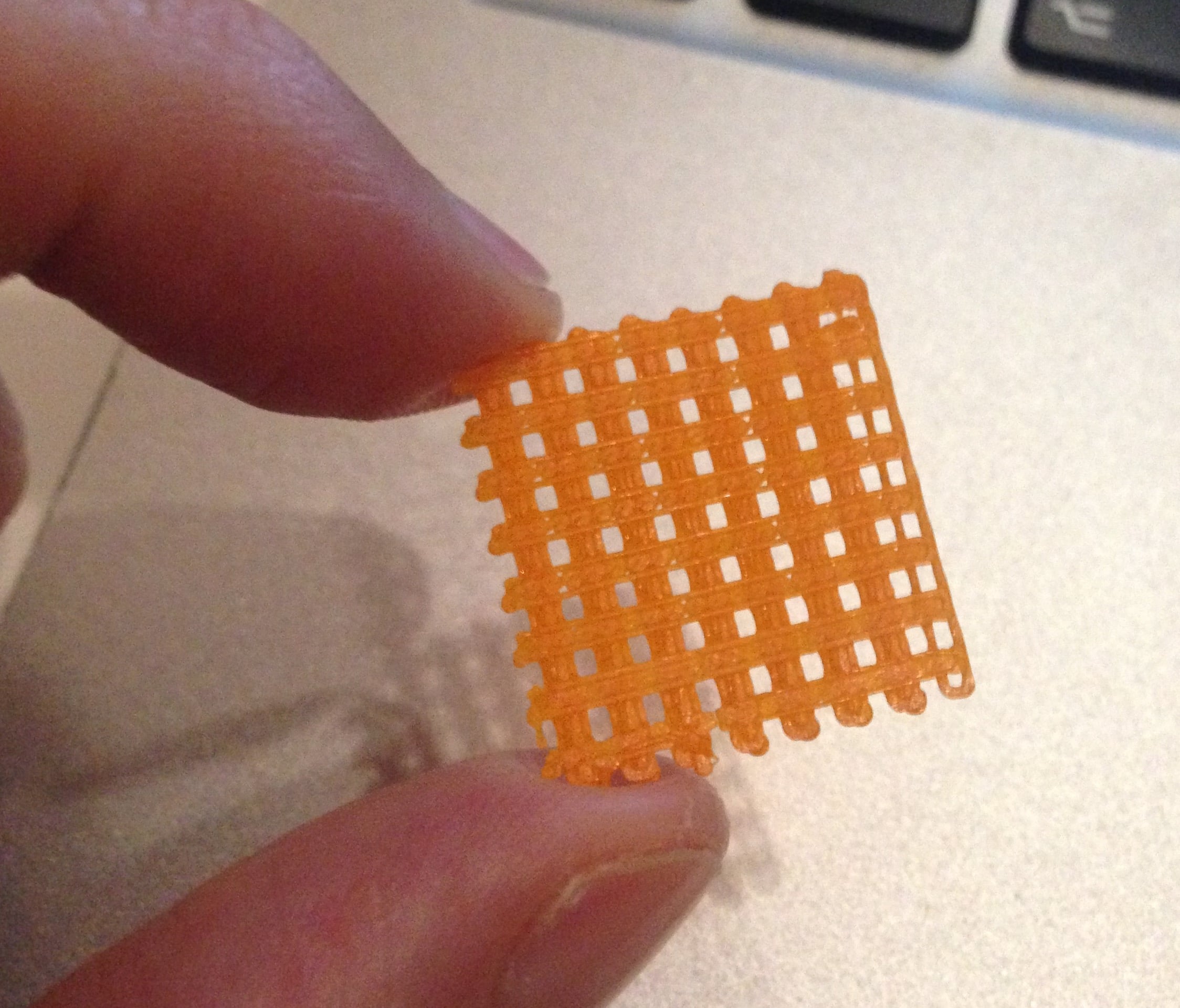

One very interesting challenge is the method of successfully 3D printing sub-millimeter holes to form the perforations. Typically this is not feasible on most inexpensive desktop equipment, but here Dorra has developed an interesting solution: print two overlapping layers where the cross-pieces form holes of the required size. Fascinating!

One concern I have is the cost to produce sufficient quantities of absorbers to cover the required surface area (the amount of sound dampening is proportional to the surfaces covered). If you’re 3D printing a lot, you will use much filament and add to your costs.

However, Dorra explains:

Based on premium PLA, at retail price, back of the napkin estimation of filament cost start around 50€ / $50 for 1㎡ of micro-perforated panels with segmented 5cm backs. This go up to 100€ / $100 for 1㎡ of 5cm cone-based back. Use of cheaper filament or bulk purchase would drive the price lower, at around 25€ / $25 for 1㎡ of micro-perforated panels.

I believe this works because the sound absorber structures are themselves quite spindly and thus won’t use a lot of plastic.

The cost structure proposed here matches reasonably well with commercial sound absorbing panels: they can be quite expensive.

However, you still must wait for the printing to complete, which might take several days depending on the requirements.

The project is built in OpenSCAD, the programming language used to develop 3D models. Thus it is very easy to change the dimensions of any component to meet the needs of a particular installation.

Finally, Dorra needs your help:

They are built in OpenSCAD, the 3D CAD programming langage, so I’m seeking the contributions of people interested in acoustic, meta-materials, and 3D printing useful structures. For example The project would benefit from the contribution of acoustic test labs to analyze and qualify the properties of the printed structures.

This project demonstrates a way to directly address a practical need in construction and interior design that everyone can make use of.

Via Github