The new B9Creation Core Series provides several interesting advantages.

It’s been a very long while since we had a story about B9, who launched the B9Creator way back in 2012. The company was one of the very first to produce a low-cost resin-powered desktop 3D printer, launched through a massively successful crowdfunding campaign that raised over USD$500K.

That placed the company among the few at the time with that style of machine, which was quite different from the plastic-filament powered machines that were prevalent in those days. The B9Creator was able to print higher resolution objects and attracted a great deal of attention.

Since then the company has been plugging along, building on that initial success by growing their market.

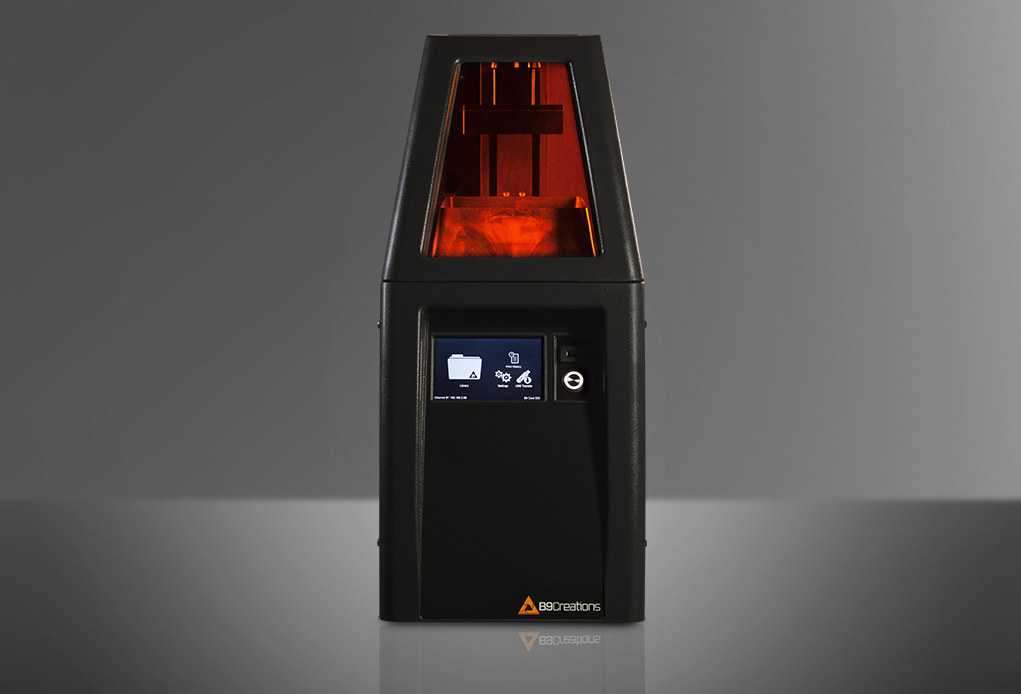

Today we see they’ve launched a pretty substantial upgrade with what they call the “Core Series”. It’s comprised of two models, the 530 and 550, which differ in build size and resolution.

The B9 Core Series 530 is the finer resolution, able to 3D print pixels of diameter 0.03mm, but only within a build volume of 57.6 x 32.4 x 127mm.

The B9 Core Series 550 has slightly poorer resolution at 0.05mm per pixel, but has a larger build volume of 96 x 54 x 127mm.

The differences are simply due to the size of the light display being focused on the liquid resin. If you focus more finely, you get more detailed results, but in a smaller size. Or vice versa. It’s the classic tradeoff: size versus quality.

But the truth be told, both machines will output excellent quality prints, and for the jewelers that will typically use the machines, the build volume is of less concern.

Why? Because jewelry is typically quite small as it is made frequently with expensive precious metals.

It’s also of less concern because jewelers have a great deal of flexibility when it comes to build volume. Typically jewelers use these machines to 3D print castable models, where the plastic is burned out and replaced with the precious metal. Often the jeweler will design a “tree” of several items that are all cast at once.

So the approach is to simply build a tree of stuff that fits within the build volume. If the build volume is too small, then your casting tree gets a couple of items pruned off for the next batch.

But back to B9Creations’ new Core Series.

What’s of most interest to me about this machine is its build speed. The specs indicate it can achieve build speeds of between 40-100mm per hour (and up to 120mm on the model 530).

Somehow B9Creations has developed techniques to bring the speed up on these machines to join the “speedy resin machine club” that several others, most notably Carbon, have developed. All have variations that permit fast or even near-continuous 3D printing in resin.

I’m glad to see that B9Creations has listed their speed as a wide range, because each of the speedy machines does have the problem of viscous fluid flow (explained here) that can constrain the print speed of particular geometries.

The machines also now include a color touch screen, full network connectivity, air filtration, auto-calibration and industrial grade components for print quality and reliability.

I cannot report on the pricing of these new models, as it is to be announced when the machines are formally introduced by B9Creations at the end of this month. However, as their previous model, the B9Creator, is still on sale for just under USD$5,000, you can bet the new models will be slightly more expensive.

Via B9Creations