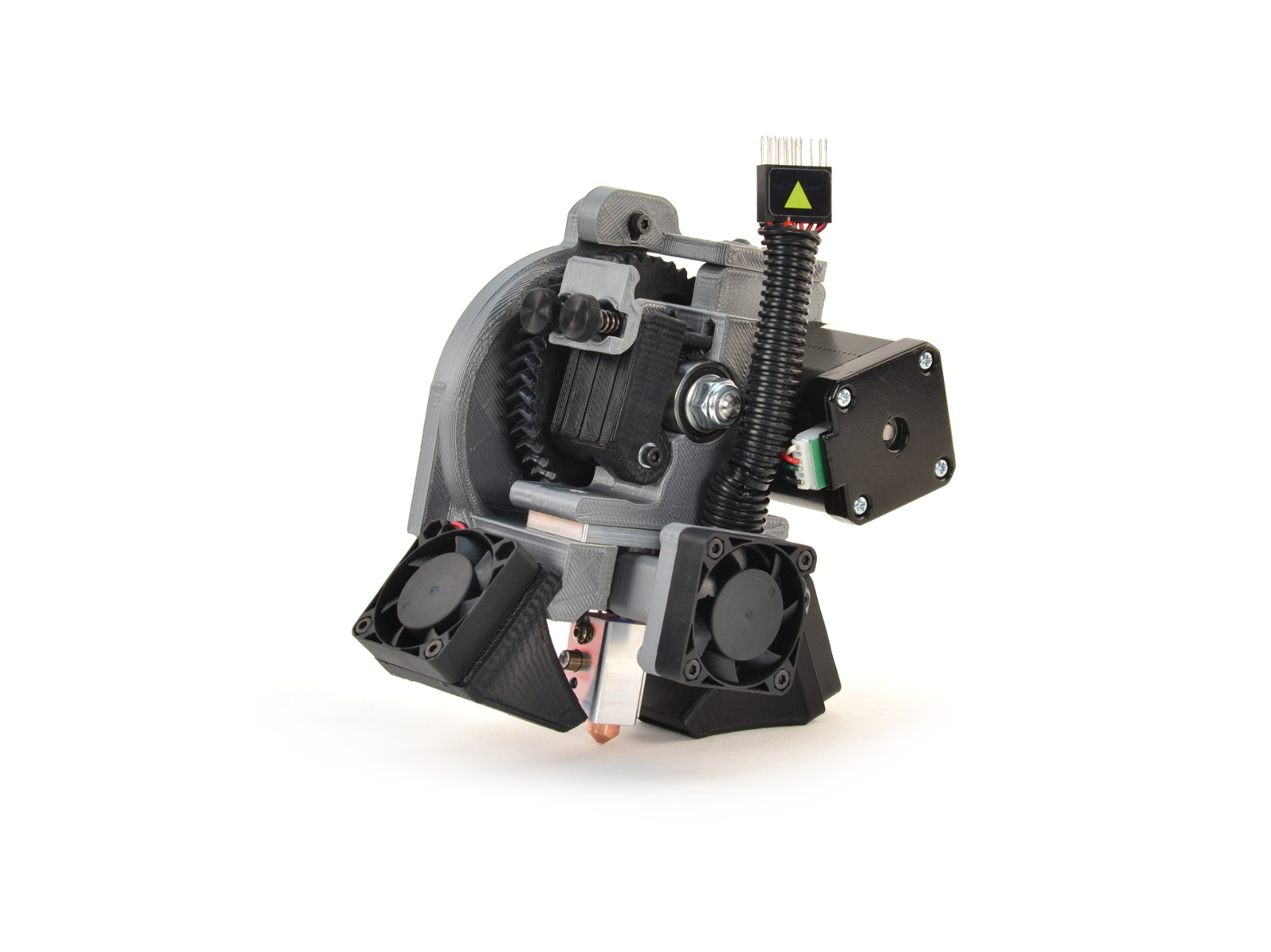

Officially, it’s known as the “LulzBot TAZ MOARstruder Tool Head”, but in fact it’s a monster extruder.

The new hardware is termed “high output”, and that’s exactly what it is designed to do: print large things really fast.

How does it do this? By enabling the machine to push a great deal more plastic through the nozzle. This is accomplished by several interesting features. One of them that we’ve seen on several other machines, is a larger nozzle diameter. While typical desktop 3D printers utilize a 0.4mm nozzle, the MOARstruder has a 1.2mm nozzle diameter. This is NINE times the size.

But there’s a lot more to it. The machinery must be able to deliver plastic softened to the precisely correct degree at the required volume. And that’s where other approaches fall down.

If you imagine a plastic filament passing through a hot end, it must remain there sufficiently long to absorb the heat and soften. But if you want to print more volume, you must be pushing that plastic at a higher velocity. This means the plastic is in contact with the hot zone for less time. At some point the heat is insufficient to properly soften the rapidly flowing plastic and printing screws up.

Here’s how Aleph Objects solved this issue: the MOARstruder has an “extra long” heater block, creating more volume where the plastic can soften. This enables more rapid movement of the plastic.

The MOARstruder is easily installed on existing LulzBot equipment as it includes their standard modular tool head carriage.

The company claims the new configuration will enable users to 3D print 100g per hour. In other words, a 1kg spool could be 3D printed in as little as ten hours! You’ll be able to 3D print layers in the 0.300-1.200mm range, speeding up print operations immensely.

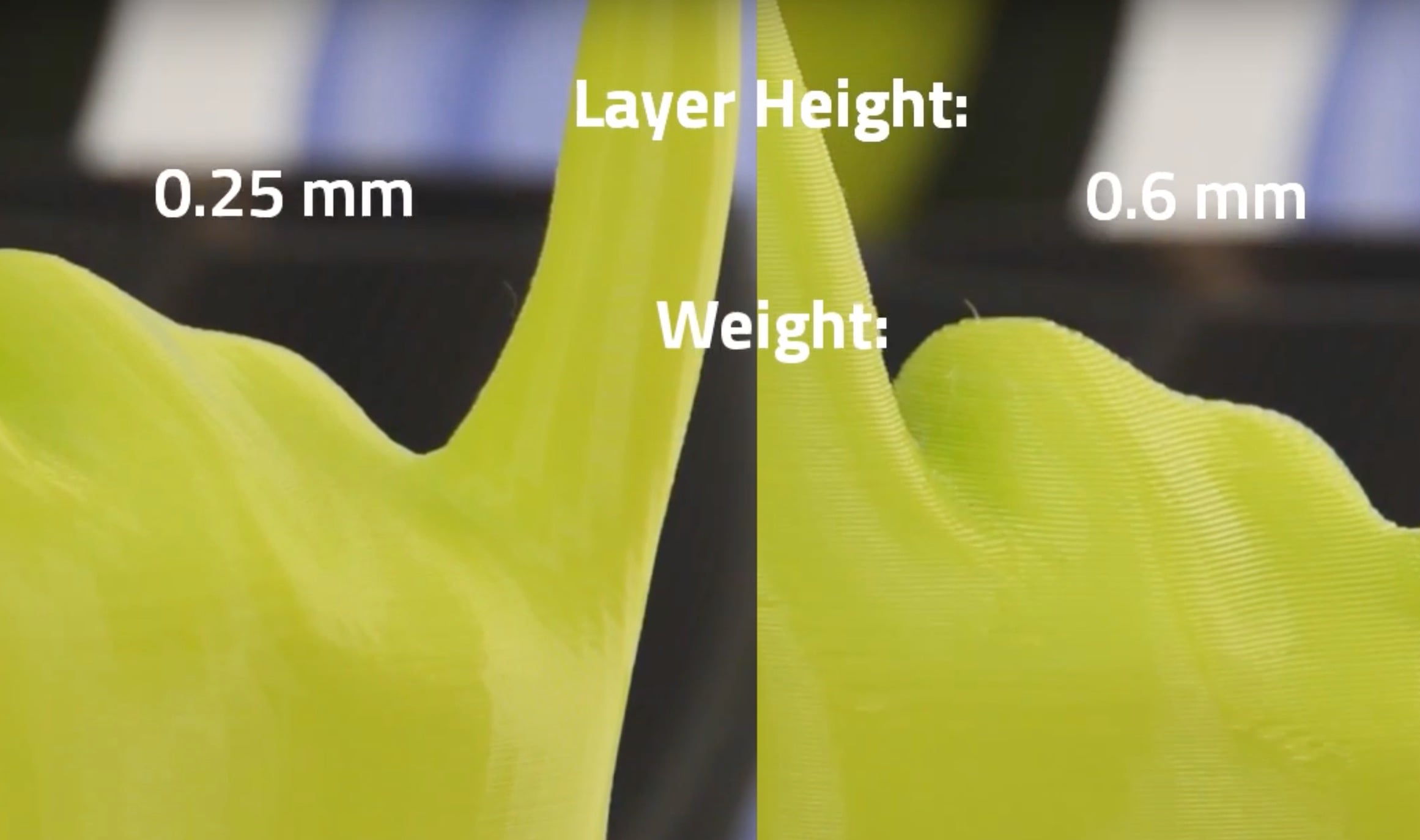

There is one caveat, however: when printing in this mode your prints will incur a surface texture penalty. They will be coarser. However, for larger objects that’s often not important as the size of the object overwhelms the appearance of layer lines.

Here you can see the difference between a “normal” 3D print with 0.25mm layers and one made with the MOARstruder at 0.6mm. The difference is very clear, and will be even more prominent when printing 1.2mm layers.

It’s the eternal tradeoff in 3D printing: Speed vs. Quality. The right answer is whatever you need for the situation, and you must choose wisely.

When will this amazing piece of hardware be available for LulzBot operators? The company says it will be released in “Q1”, which might include any date up to and including March 31st. No word on pricing yet.

[UPDATE] Based on a comment received, we asked Aleph Objects directly whether this new extruder is in fact the E3D Volcano unit. They replied that it is in fact a collaboration between their company and E3D, who actually manufacturer the MOARstruder. It’s NOT a Volcano, but shares many elements as both companies brought their knowledge together to produce a new extruder. But what’s more important is that the MOARstruder is not just a piece of hardware; it is a “system” that includes not only the extruder itself, but also the printing profiles and machine leveling adjustments that automatically take place once the hardware is installed and LulzBot’s software is used.

Via LulzBot