We examined samples from 3ntr’s equipment and found them very capable.

3ntr is a 3D printer brand from Milan-based Jdeal-Form, a five decade-old manufacturing company, who have plenty of experience with polymers and building making machines of all kinds.

The company entered the 3D printer market recently and has produced several models including the A2 and A4 models we examined.

Like several companies, 3ntr is attempting to break into the prototyping market pioneered by Stratays. Their strategy is to increase the quality, broaden the number and type of materials printable and reduce costs all at the same time. And from what I saw, it appears they’re doing so successfully.

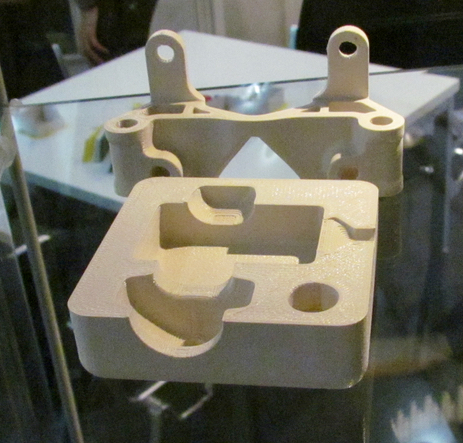

The A2, shown here, is able to print in ABS, HIPS, IGLIDUR, Nylon/Carbon, PA66+Glass, Polycarbonate, PC-ABS, PET-G, PLA, SSU01 and TPU, which is quite a variety of powerful materials. We were told this machine can 3D print “any available material.” It has a very generous build volume of 620 x 350 x 490mm and can print layers as small as 0.05mm at a maximum print speed of 200mm/second.

The nozzle goes up to 410C, able to handle almost all materials available today. What’s more interesting is that the build chamber is heated and can run at 80C, making for extremely reliable 3D printing. I asked whether their design violates the Stratasys heated control patent and was told they do not because the independent heating elements are inside the chamber itself. I suppose that makes the heating design sufficiently different.

The A4 model is identical except that it has a somewhat smaller, but still generous build volume of 300 x 200 x 190mm.

Both machines feature an interesting carbon fiber build plate that is said to be “always flat” and requires “no calibration”. The plate also features automatic adhesion. I’d show you a picture but we were asked not to show it publicly yet.

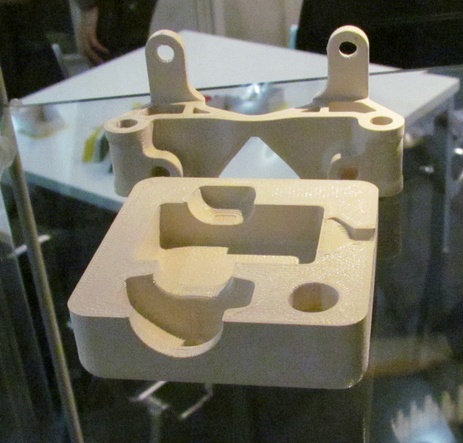

I examined sample prints from these machines and found them to be of exceptional quality. The edges are very sharp, surface texture is near perfect.

Here you can see a large industrial part printed on a 3ntr machine that shows the detail possible.

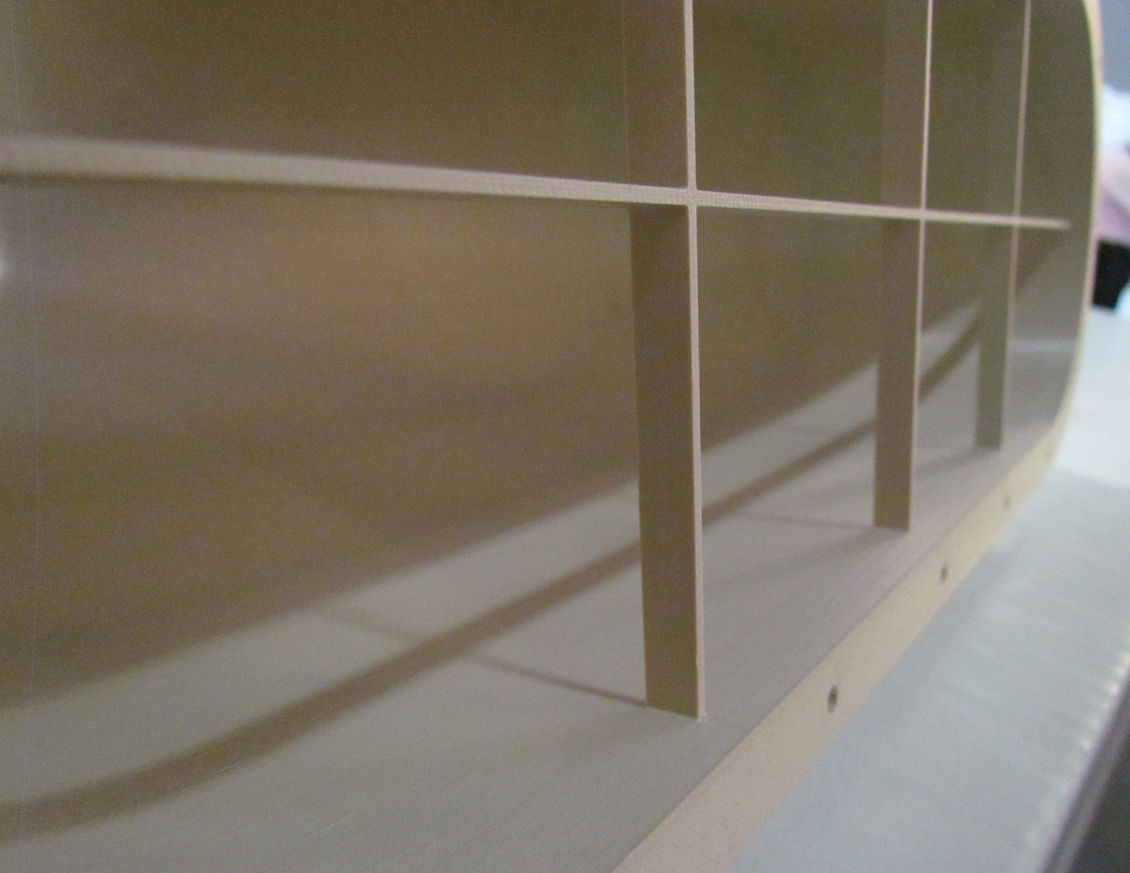

Some of their quality success may be due to their propriety support material, which is apparently engineered to operate at very high temperatures.

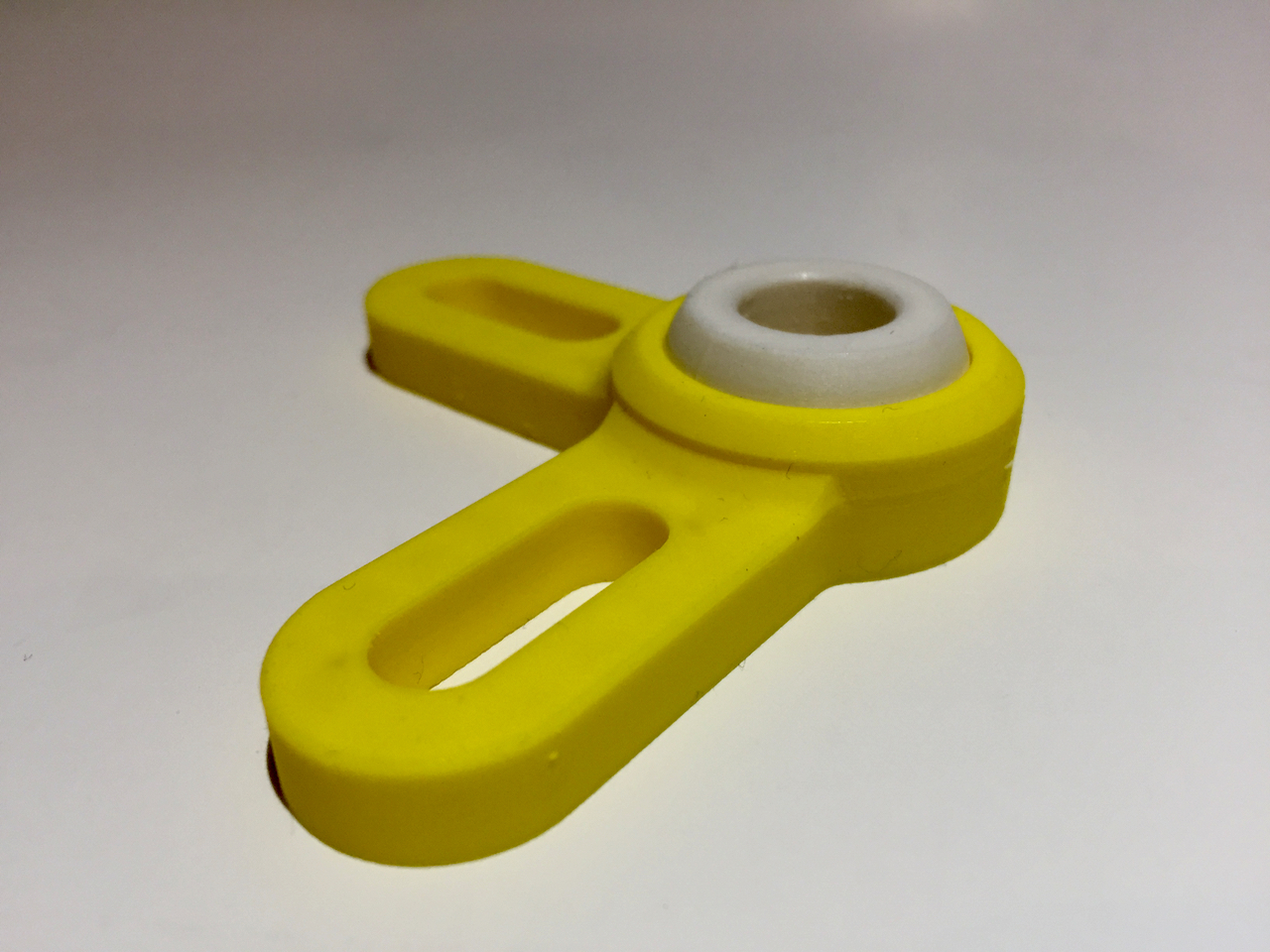

The tolerances on this machine are quite incredible. Here is a ball joint that was 3D printed without support material, and it’s near perfect. Pictures are hard to tell this story, but suffice to say that it moves quite smoothly in the joint.

The materials capabilities on these machines make for some interesting applications. Here we see how they have mixed hard and soft materials together to produce an interesting hybrid object.

The company has leveraged it’s long experience with polymers to develop a new 3D printing material they call “nPower”. It has great thermal resistance, up to 210C, and is unaffected by chemicals or acids. It’s also “self extinguishing”, but I’m not quite sure what that means, so I looked it up. nPower meets “UL94 V0”, which states:

V-0: burning stops within 10 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed.

Certainly a good attribute for any filament.

Anyhow, 3ntr explains that nPower is 5X less expensive than PEEK, which might be of interest to some operators.

Now you might be wondering of the price for these machines, and I cannot tell you, as we were told the prices are set by 3ntr’s resellers.

Via 3ntr