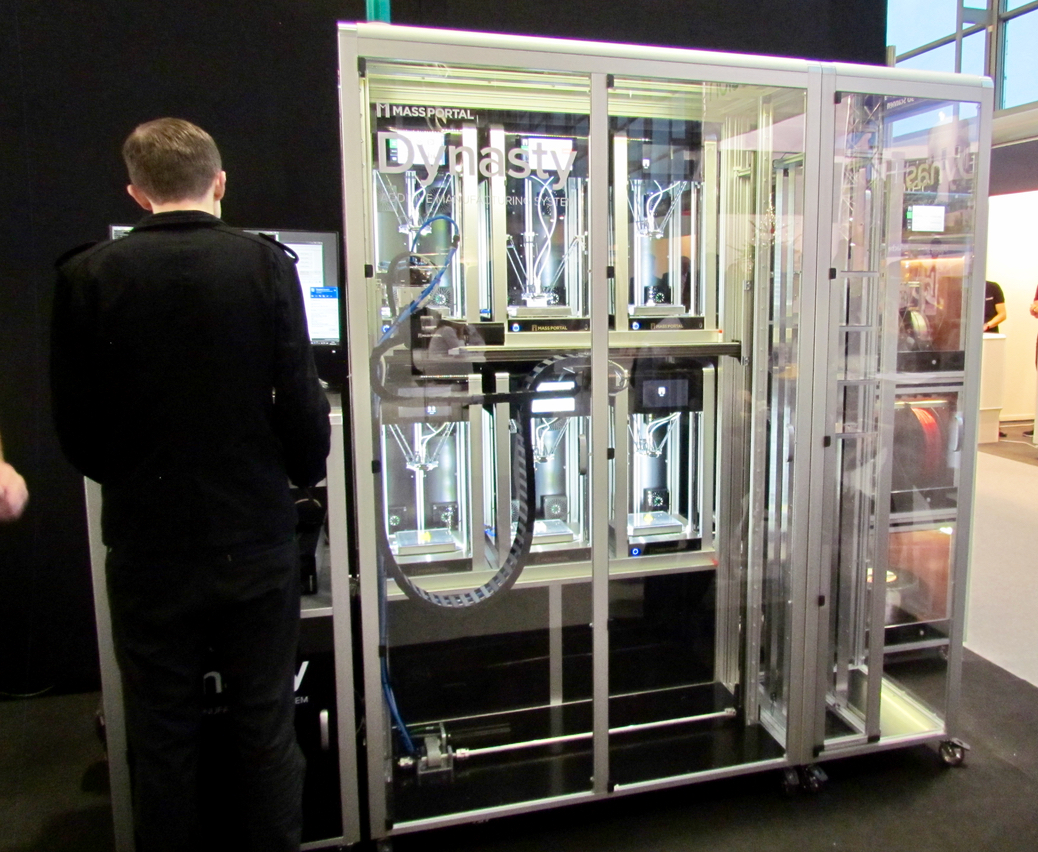

Lativa-based Mass Portal has developed a powerful rack-mount system for parallel 3D printing.

The “Dynasty” system is based on the company’s previously successful delta-series of desktop 3D printers. These machines produce among the finest output I’ve ever seen from a plastic 3D printer – and they can even print when sideways!

Now the company, like many other desktop 3D printer manufacturers, is getting deeper into industry by introducing a rack-mount system for addressing the needs of low-volumed manufacturing. The idea is to have multiple reliable 3D printers ready to go, able to 3D print multiple copies of an object quickly, or produce multiple unique items in parallel.

The rather dense arrangement permits up to six standard units together, four of their mid-size printer units or two of their large-sized 3D printers in the rack. Of course, you can add as many racks as you like.

But this isn’t just a fun shelving system; the Dynasty offers a number of very appropriate workflow features:

- The accompanying software provides “intelligent dispatch” of work to unused equipment within the rack.

- The rear of the rack is clear and can be used for repairs, which by the way minimizes failures due to the parallel nature of the system.

- Filament is supplied by adjacent storage units that also double as filament dryers to ensure maximum reliability.

- A robot delivery system moves empty build trays from storage to printers and completed build trays to another storage area.

- The system is designed for 24/7 operation.

The company sees three different markets for this system. One is obviously unattended operations, where a manufacturer can let the system churn out prints as fast as it can, without the need for constant human intervention.

Another market is low-volume manufacturing, where someone needs to produce a quantity of items that is so low it doesn’t justify the production of expensive injection molds, for example.

Finally, and this is the most interesting application as far as I am concerned, is materials development.

Unlike some other rack-mount systems I’ve seen, the Mass Portal 3D printer is capable of using arbitrary plastic filaments. This means that you could, say, print a single object on multiple machines, each trying a different material. In other words, you can very rapidly test your item in many materials. That’s a critically important step in the design of functional objects.

This goes directly towards one of the key applications of 3D printing: prototyping at scale.

Via Mass Portal