I’m looking at a new startup focused on use of recycled plastics for the production of 3D printer filaments and have some thoughts.

The company in question is ALT LLC, a California-based company that is pursuing this idea. They’re hoping to launch via a crowdfunding soon.

What’s interesting is the motivation behind their launch: it seems that the US state of California has announced new recycling goals that hope to move recycling activity up to 75% of materials by 2020. To put this in perspective, the US currently recycles only 9% of its waste. This is quite a contrast to some European locations, where close to 100% of material is recycled.

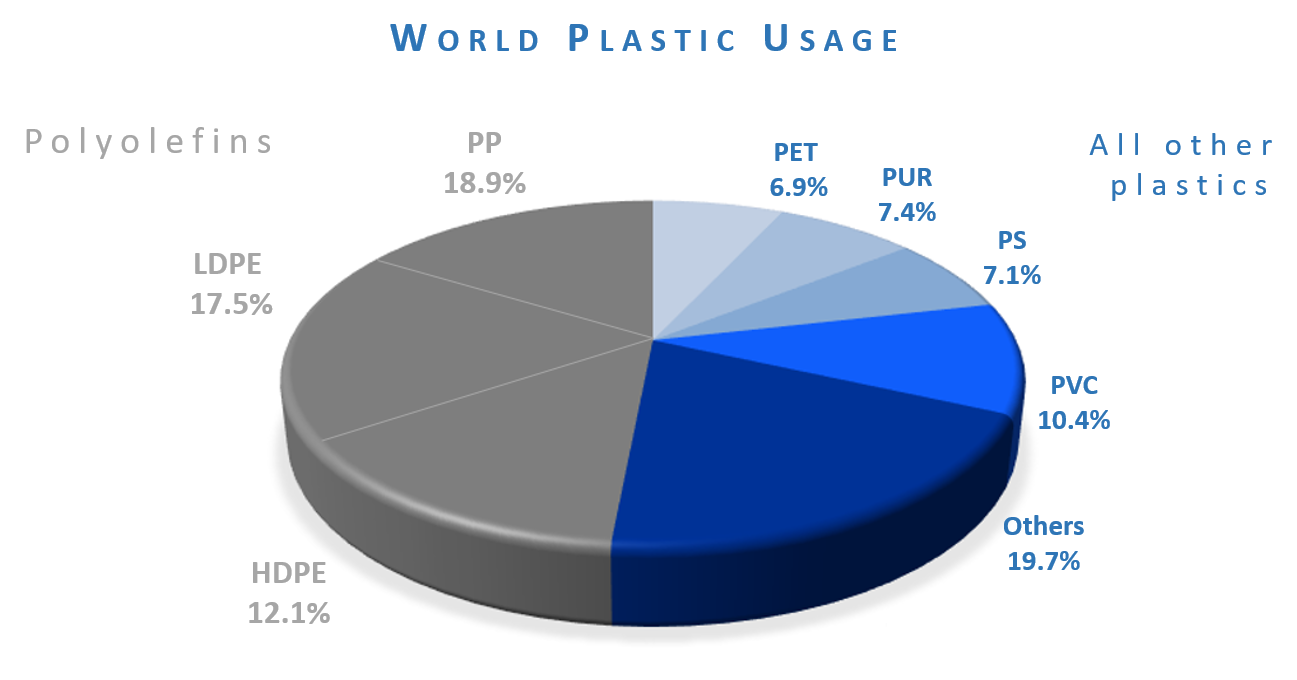

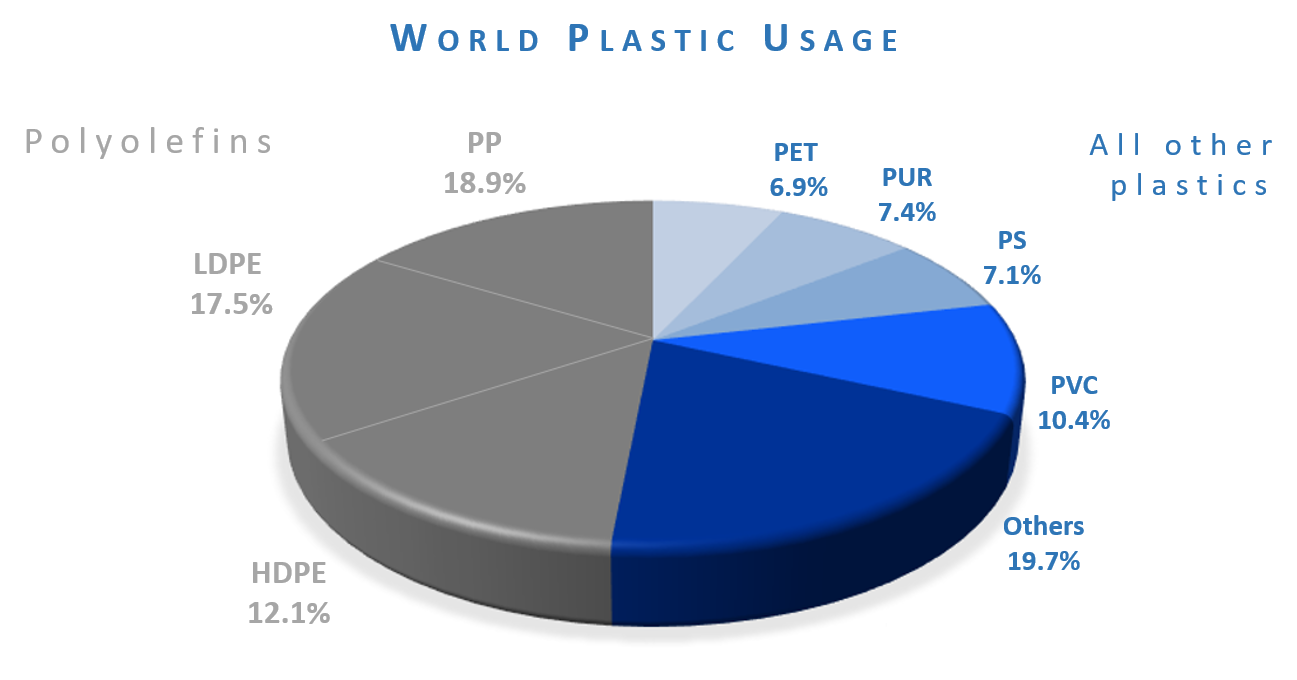

ALT LLC is focusing on particular plastics that happen to be prevalent in public use, including Polypropylene (PP), Low-Density Polyethylene (LDPE), and High-Density Polyethylene (HDPE). These are materials used in some 3D printers, but certainly they are not by any means popular materials.

This is an admirable initiative, but there are great challenges.

First, the amount of plastic consumed is truly staggering. There’s in excess of 30M tons of plastic used in the US each year, the weight equivalent of 30 BILLION 1kg spools of 3D printer filament. Hoping to make a significant dent in the recycling stats through this approach is unrealistic, although the goal is admirable.

Second, there is the matter of printability. Current 3D printer filament makers attempt the best ways to develop materials that are in fact printable. Poor filaments break, don’t stick to the bed, have poor extrusion temperature ranges and other effects. They do this by adjusting the chemical mix to gain or lose properties to improve performance.

The result is a very precise chemical mix that best meets requirements. But in the case of recycling, the input plastics are not necessarily the same mix of chemical substances, as they are gathered up from a variety of sources. I am aware that some recycling programs attempt to overcome this challenge by say, gathering plastic bottles only from a particular vendor. But that greatly restricts the amount of type of plastics being recycled.

Finally, there is a new challenge facing those attempting to recycle plastic for 3D printing: material demands.

Today the use of desktop 3D printers that use such filament are shifting focus towards more specific materials. The goal is to produce objects that can actually be used in real life applications or engineering prototypes that have specific mechanical, thermal and chemical properties.

In other words, there’s an increasing demand for VERY specific plastics.

And those are not necessarily going to be the most easily recycled plastics.

Nevertheless, if you can use HDPE, PP or LDPE, you might want to watch for ALT LLC’s launch of their new line of 3D printer filaments.

Via ALT LLC