The notion of buying a desktop 3D printer that is sufficiently flexible to print in many materials isn’t enough.

You will find machines available that purport to 3D print many materials, and indeed you can try. The basics are straightfoward:

- The machine must have a hot end capable of reaching the necessary high temperature for many materials

- The machine must provide a suitably heat-controlled environment for the printing to take place

- The machine must provide some method of appropriately securing the print to the surface during printing – and release it after completion

A machine having those characteristics might be able to attempt to 3D print any number of materials.

There’s just one problem.

What are the correct printing parameters for the specific material? What speeds, flow rates, retraction settings and temperatures are optimum for that material?

If you don’t know, you can find out through trial and error. Believe me, this isn’t a fun job. It is a repeating series of failures and one final success.

The best approach is to make use of a pre-determined print “profile” that includes all the settings for an optimum print. In other words, use someone else’s time and trouble when they figured it out by trial end error.

Some vendors are beginning to do so, providing increasingly comprehensive lists of material profiles for their equipment.

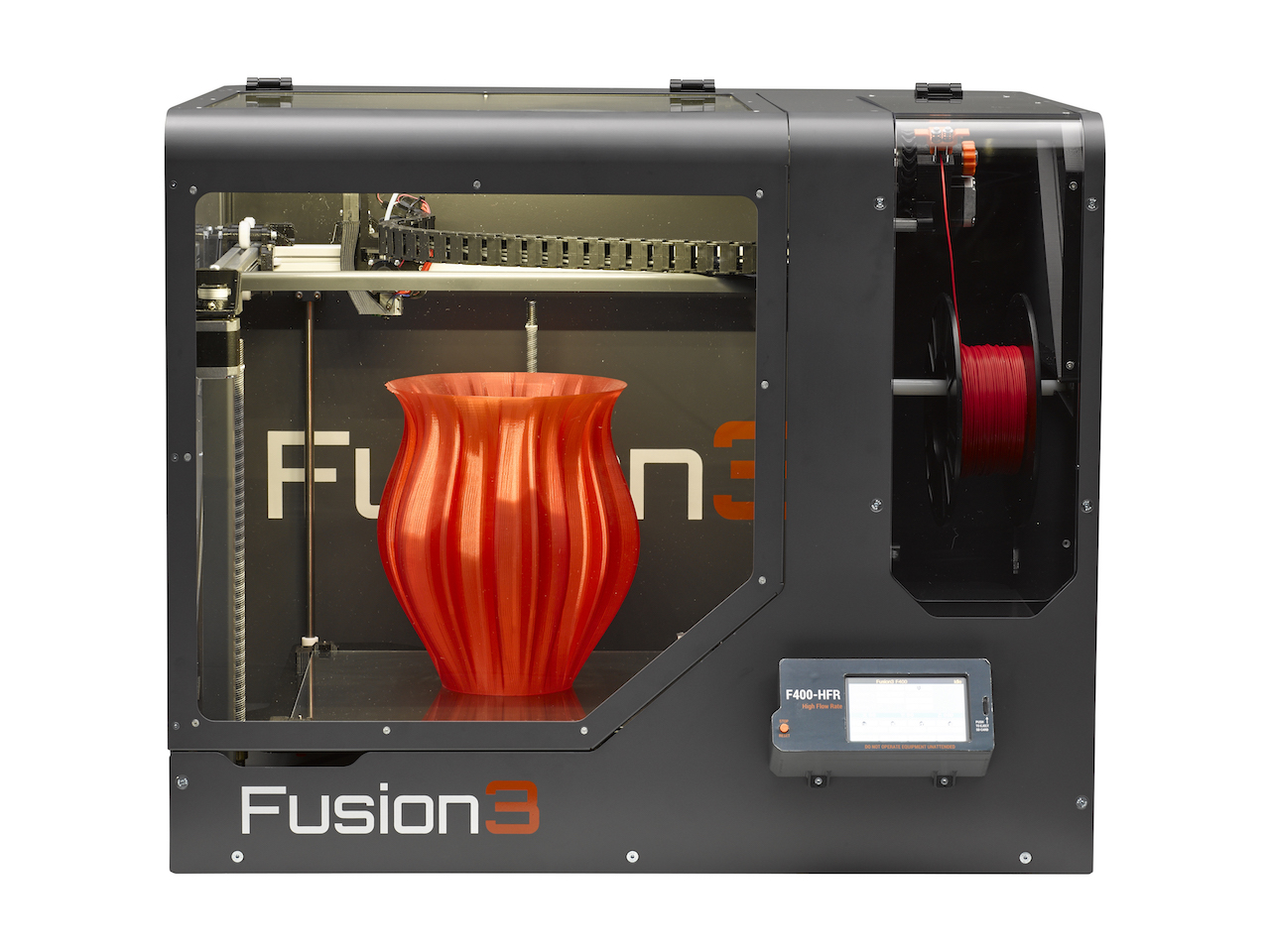

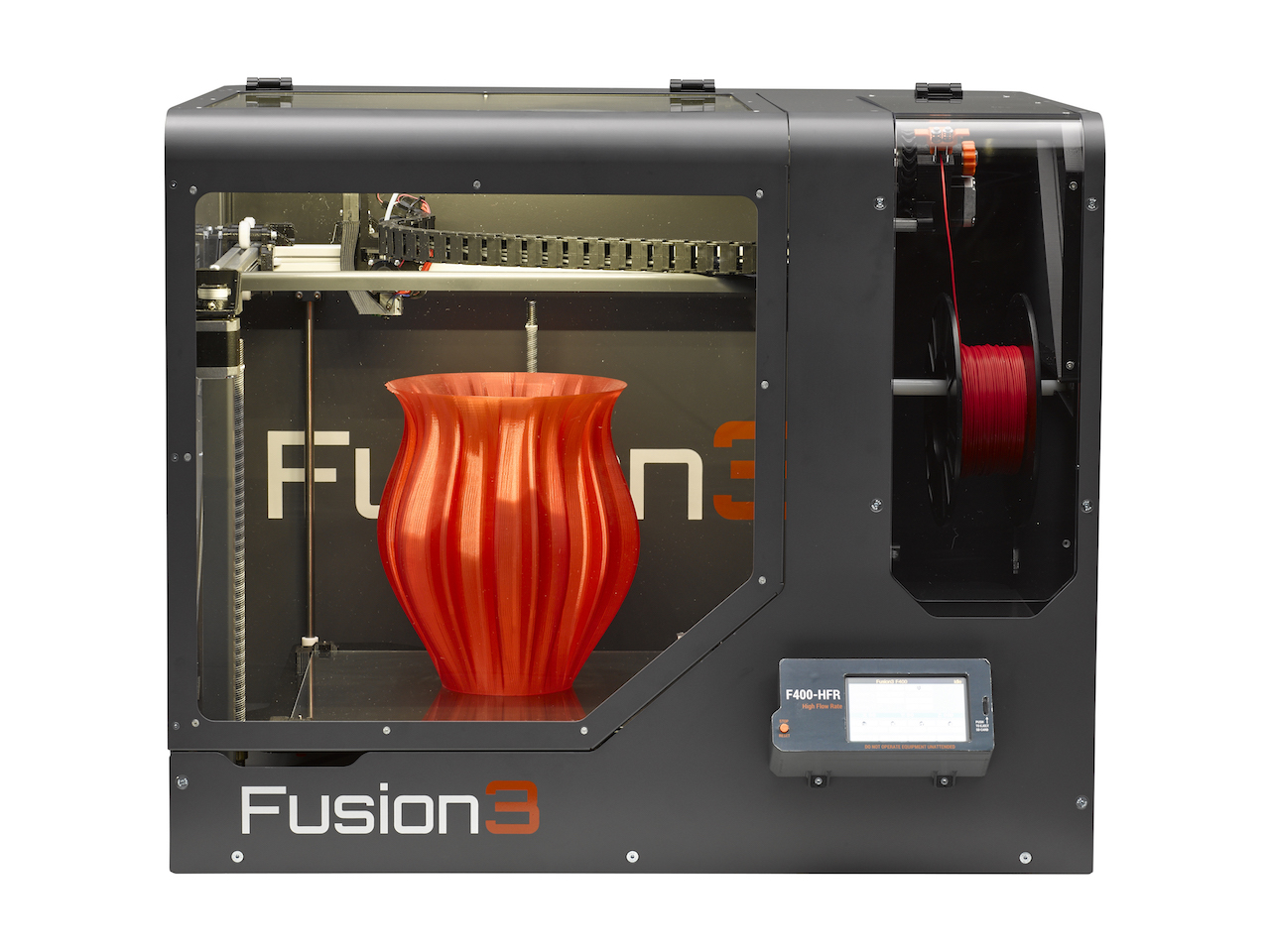

One such vendor is Fusion3, who make the very powerful F400 machine that we detailed earlier this year.

The company announced that it has now certified (meaning it has print profiles for) over 35 different materials:

The company has certified over 35 different formulations of generic and specialty 3D filaments produced by 13 of the world’s leading 3D filament manufacturers. Tested and approved filament categories now include generic and specialty formulations of PLA, ABS, ASA, PET, PETG, PC-ABS, Nylon, Polycarbonate, Flexible (TPU/TPE), Polyester, Acrylics, and HIPS (soluble).

And note that these plastics are by vendor. This avoids the situation where your ABS settings worked with one vendor’s ABS filament, but not another’s. They say:

These certified materials are produced by a ‘who’s who’ of leading North American and European 3D filament manufacturers including Atomic Filament, ColorFabb, E3D, Fillamentum, MakeShaper, NinjaTek, ProtoPasta, ProtoParadigm, Taulman3D, 3DXtech, 3D-Fuel, Toner Plastics, Ultimachine and Verbatim.

Recently they added ASA, several flexible TPU plastics and PETG to their catalog of profiles.

The use of print profiles is critical for open materials machines. Proprietary material machines already have such profiles embedded in their systems, and that’s why they often have superior results. But with well understood print profiles, open material machines can have the same good results.

And one of the widest catalogs of print profiles can be found at Fusion3.

Via Fusion3