California-based William Osman has been experimenting with a homemade sand-fusion system based on a laser cutter that could eventually become a full 3D printer.

The powder process in the world of 3D printing is well understood and has been used in a number of variations using lasers, binders and other approaches. In fact, there are commercial 3D sand printers available from several vendors, including VoxelJet, but they tend to be rather expensive.

However, there are far fewer powder-based machines of desktop size and I’m not sure there are any that produce prints in sand. There was one experiment in which an artist developed a kind of sand printer using solar energy. Markus Kayser’s “Solar Sinter” project would focus the sun’s light to selectively melt desert sand.

But that very project also inspired Osman to experiment with sand printing.

Osman is one of those folks who builds complex personal projects, such as a Kinetic Gimbal Controller, or an Open source motion control system. He’s also built 3D printers, and a 90W laser cutter.

The laser cutter is typically used to cut or engrave 2D materials, such as wood, cardboard, plastic or metal. However, Osman realized after seeing Kayser’s experiment that he might be able to try the same sort of process using his home-built laser cutter.

This was truly an experiment, as Osman didn’t know whether the laser would be able to melt beach sand.

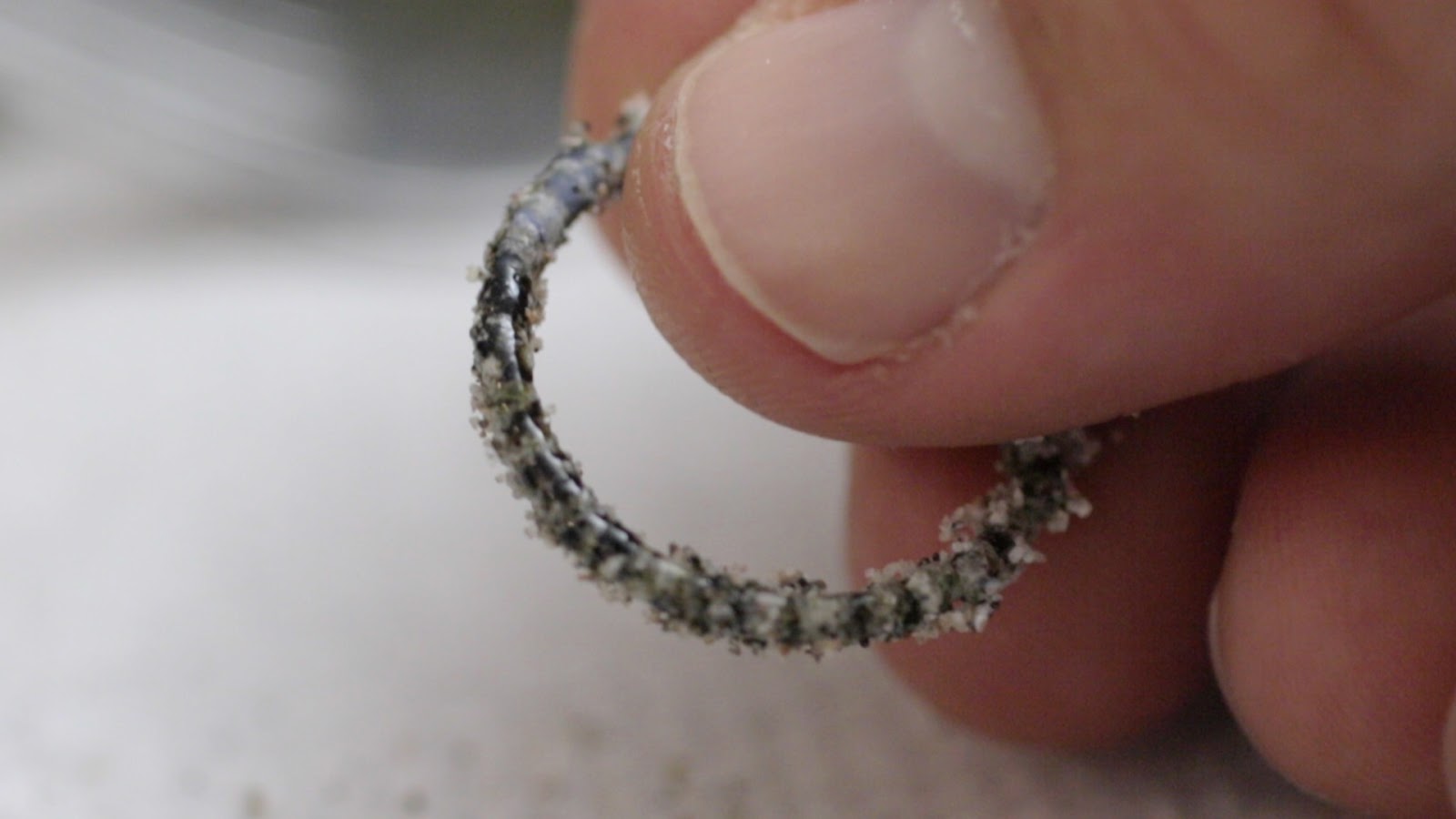

His initial experimental “melts” didn’t work so well, but he realized he had to use sodium carbonate as a flux to lower the melting temperature of the sand. Once this was added, he was able to successfully fuse sand into solid-ish objects, such as the circle and star shown at top.

While the process has been relatively successful as a proof of concept, a future step would be to engineer a method of adding layers of sand so that 3D objects could be created.

It sounds like there is a great deal of investigation left to this project, as the type of sand, flux chemistry, temperatures and feeder system must be developed. If successful, this could lead to a low-cost DIY 3D sand printer that some may find quite useful.

Such a device could be used to not only create sand objects, but also produce sand molds into which plastic or metal objects could be formed.

But then there’s one more challenge to overcome: potential patents on this process.

Via William Osman