With increasing interest in unusual 3D printing materials, a corresponding increase in adhesion solutions is occurring.

Italy-based Northype produces an adhesion plate accessory for open 3D printers that can greatly assist the problem of material adhesion during 3D printing operations.

Adhesion is a critical issue during 3D printing, as any 3D printer operator will immediately attest. Solutions are quite varied and involve specialized plates, chemical applications, tape, sprays and other unusual and often messy approaches.

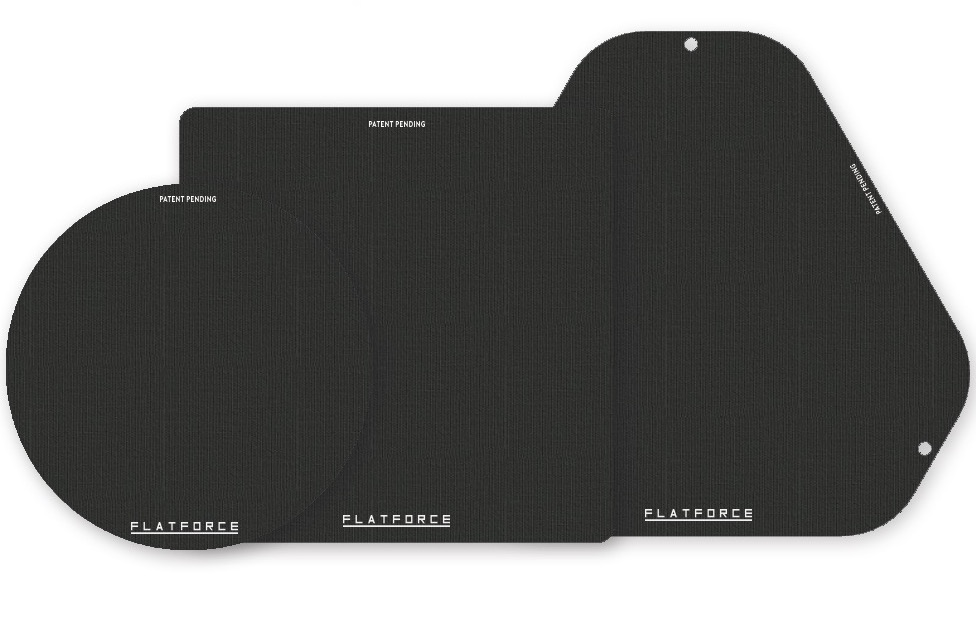

Many 3D printer manufacturers today produce devices with heated build plates that do work with many plastics, but sometimes that isn’t sufficient. It’s not uncommon to see a heated build plate with Kapton tape applied to ensure the ABS will stick. So heated plates are not always the answer.

Northype produces a specialized plate that can replace the glass plate on your heated build platform to provide additional adhesion. Their claim to fame is that they are able to provide adhesion for a much wider variety of materials, including many engineering materials such as nylon. In fact, they boast of 47 tested materials as of this writing.

With such a print surface, you can actually reduce the heat of your build plate and still obtain suitable adhesion. Here is the comparison chart for the FlatForce plate:

This is a very useful accessory, as it greatly simplifies the print operations by avoiding the application, maintenance and monitoring of secondary solutions like tape, liquids and sprays. It should also increase print reliability and even reduce your print times by reducing the heat-up time for the build plate.

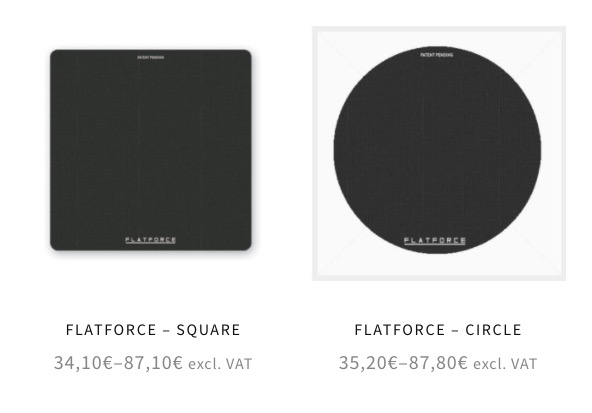

The FlatForce plate is available in multiple sizes and shapes, with prices ranging from a low of €34 (USD$) to €87 (USD$).

Via Northype