Airwolf 3D has announced a new adhesion solution for 3D printing polypropylene.

With the increasing interest in 3D printing a much broader set of engineering materials as we described recently, there is a corresponding increase in the interest in adhesion solutions. You can’t use an exotic material unless you can make it stick to the print bed when 3D printing!

Most 3D printers today include standard solutions for standard materials, such as ABS or PLA. A heated build plate enables quite a few different materials to adhere while heated. When cooled, some materials shrink imperceptibly, causing them to be released from the cool plate.

However, that approach doesn’t always work best for every material. One material that’s getting increased interest is polypropylene, that can be used for making production-quality parts.

Previously, a typical workflow was to 3D print an object in ABS plastic iteratively to arrive at a final design. Then it would be used as the final design for producing a metal mold into which polypropylene would be injected to create final production objects. But if you could simply 3D print polypropylene effectively you’d cut out a lot of steps – and expense.

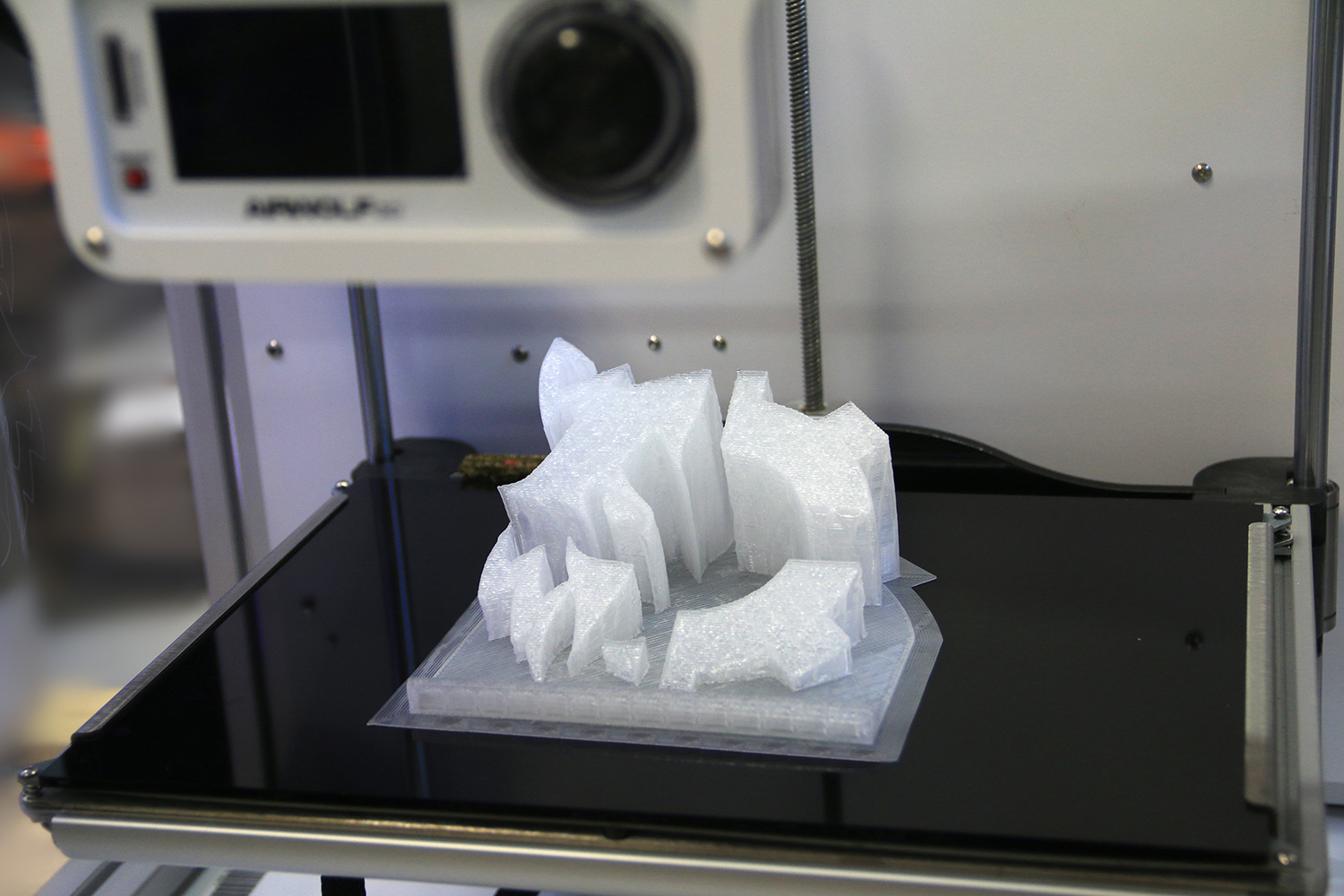

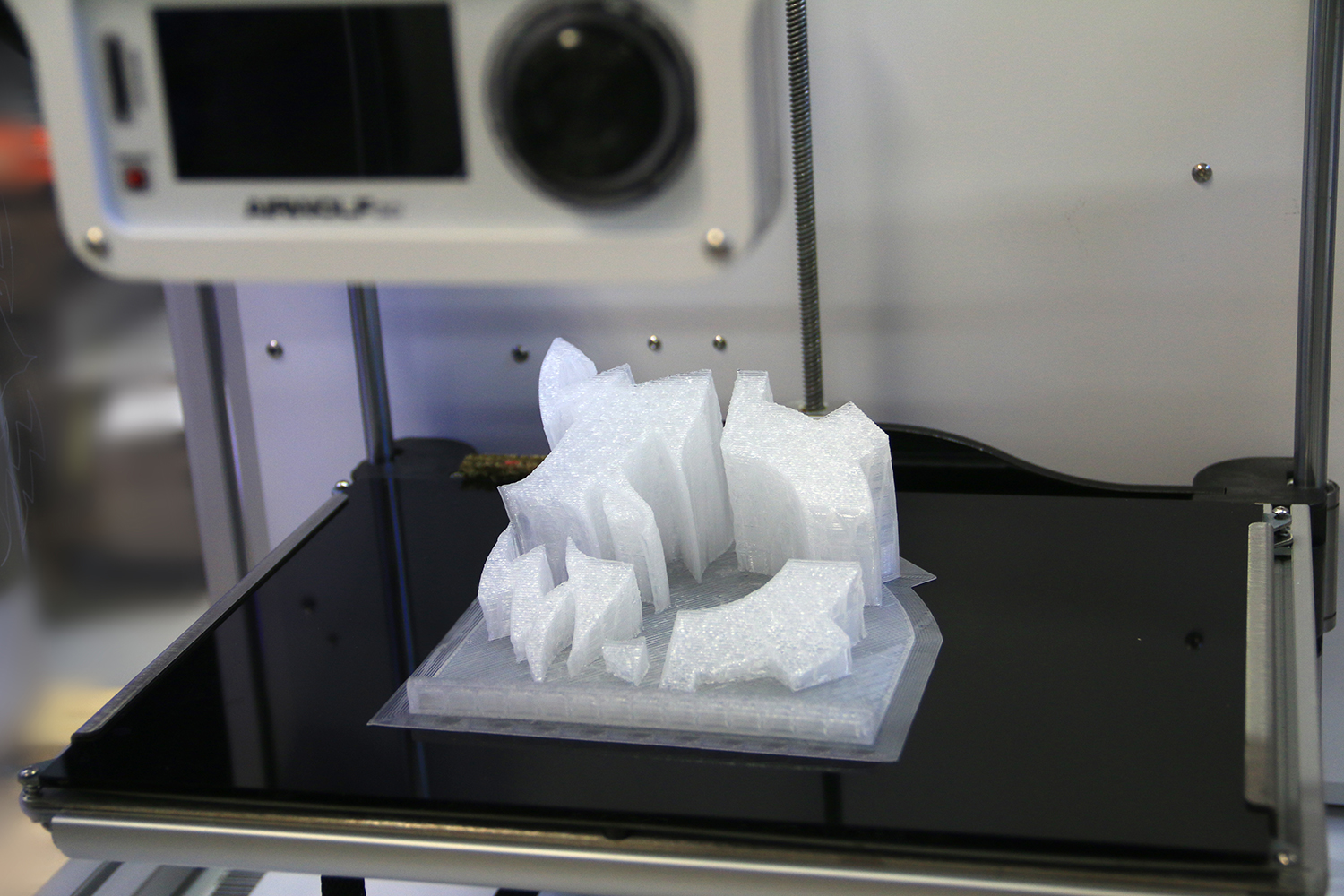

Airwolf 3D’s 3D printers can print polypropylene and many other materials, but they’ve released a solution specifically for polypropylene material:

Wolfbite ULTRATM, a premium solution specifically engineered to solve the problem of polypropylene parts warping because they fail to adhere to a 3D printer’s build plate. Wolfbite ULTRA ™ bonds polypropylene plastic parts to a build plate to allow printing without lifting and to enable smooth release of objects after printing. This new solution works well with heated beds on all types and brands of 3D printers utilizing glass printing surfaces.

Airwolf 3D now sells 2oz (60ml) bottles complete with a foam applicator for only USD$20. It’s easy to use, just paint it onto the print surface with the applicator and you’re ready to print.

Via Airwolf 3D

http://airwolf3d.com/