Israel-based XJet Ltd. announced they’ve been able to successfully 3D print ceramics using their proprietary NanoParticle Jetting process.

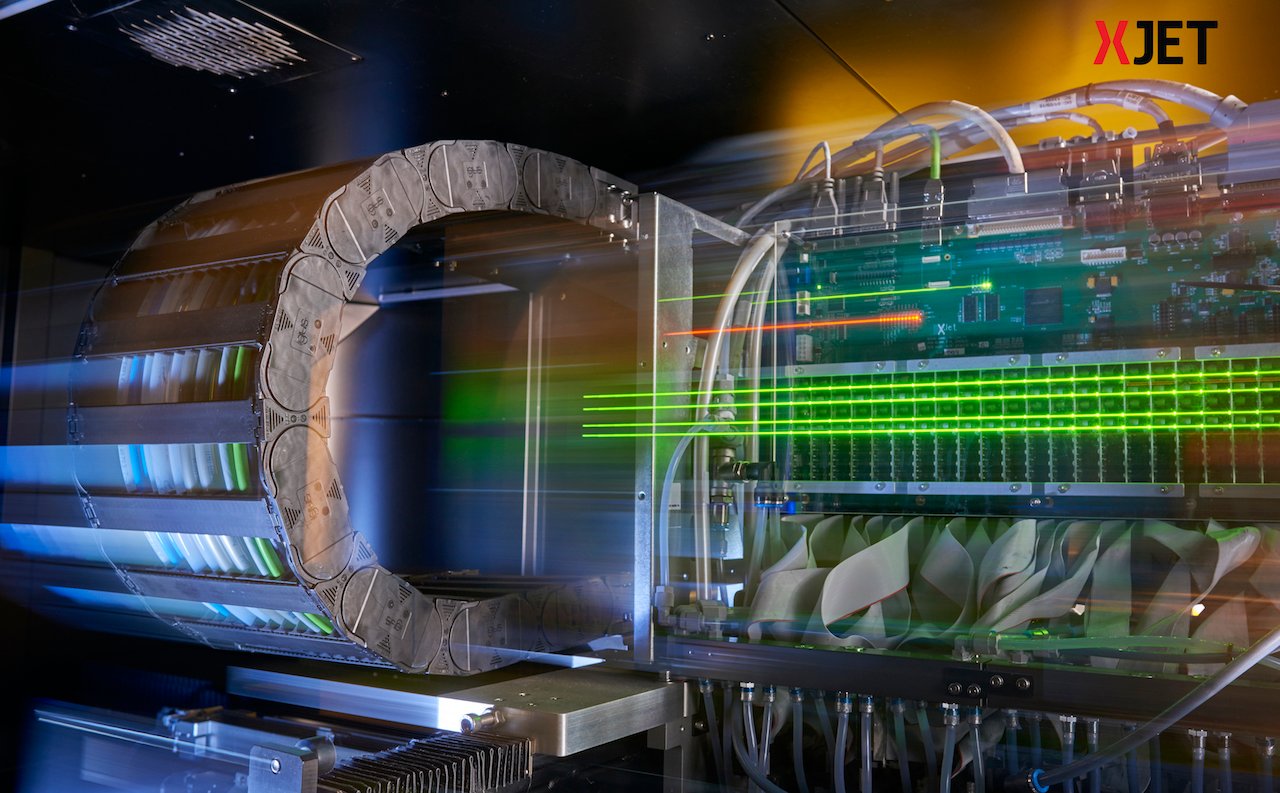

The company’s NanoParticle Jetting Process, a.k.a. NJP, is a new process is quite different from other 3D printing processes. It involves using inkjet-like print heads to deposit a mixture of liquid solution and nano-sized printing material. The depositions are subjected to high (+300C) temperatures, which causes the liquid solution “jacket” surrounding the nanoparticles to instantly evaporate and fuse the metal particles together in final position.

The process can produce very high resolution prints, as the inkjet and nanoparticles are of very small size.

But as you might imagine, it’s entirely possible to put nanoparticles of other materials into the solution. In their recent announcement, they’ve apparently been able to succeed in printing ceramics by using the same process by substituting ceramic particles instead of metal. It’s not clear from their announcement whether the ceramic sintering takes place during the print or is a post-printing activity, but regardless, this is a powerful method to produce 3D printed ceramics.

The NJP process does require support material that is not fully described, as far as I can tell. However, they say that the support material is separate from the model material and is “easily removed”. This suggests that it is a different material, perhaps being deposited by separate print heads.

I’m interested to learn more when we visit with them during the FormNext exhibition next week.

Via Xjet