While plenty of exciting developments are happening in the product design space, few are as revolutionary as advancements in generative design.

The result of artificial intelligence and the simulation of complex scenarios has enabled modern CAD software to play a participatory role in generating forms based on specific inputs provided by a user. The result is not only an entirely new way of manufacturing or creating products optimized for their specific applications, but also an entirely new aesthetic rooted in organic form.

While many of these parts—primarily produced through metal-based additive manufacturing methods—have been reserved for aerospace and racecar applications, The Elbo Chair, created by Autodesk Technical Assistant to the CEO Arthur Harsuvanakit and design intern Brittany Presten, is a perfect example of what can happen when the software is brought down from an aerospace engineer tool down to an artisanal craftsman tool.

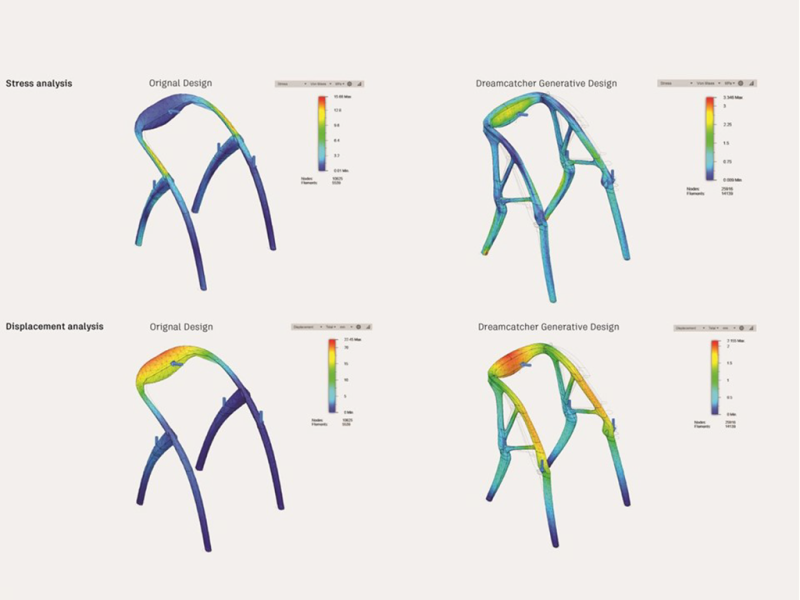

Created as a nod to Danish furniture master Hans J. Wegner’s ‘Elbow’ chair, the Elbo was created using both Autodesk Fusion 360 and Autodesk Dreamcatcher using load condition parameters based off of the weight of the average person sitting in the chair. The resulting design was split into ten separate components with each carved from Black Walnut using a CNC router. To create the organic forms with the CNC router, they machined the top side of each piece, then flipped the piece into its negative mold to secure the piece while the CNC router machined the bottom side.

Read the rest at SolidSmack.com