When you think of “Roland” with respect to making machines, you think “small desktop unit”. But that’s definitely not going to be the case soon.

Previously we inspected their desktop resin 3D printer / milling machine combo, the “monoFab”. It’s an interesting desktop unit suitable for makers and prototypers. And it’s not very big.

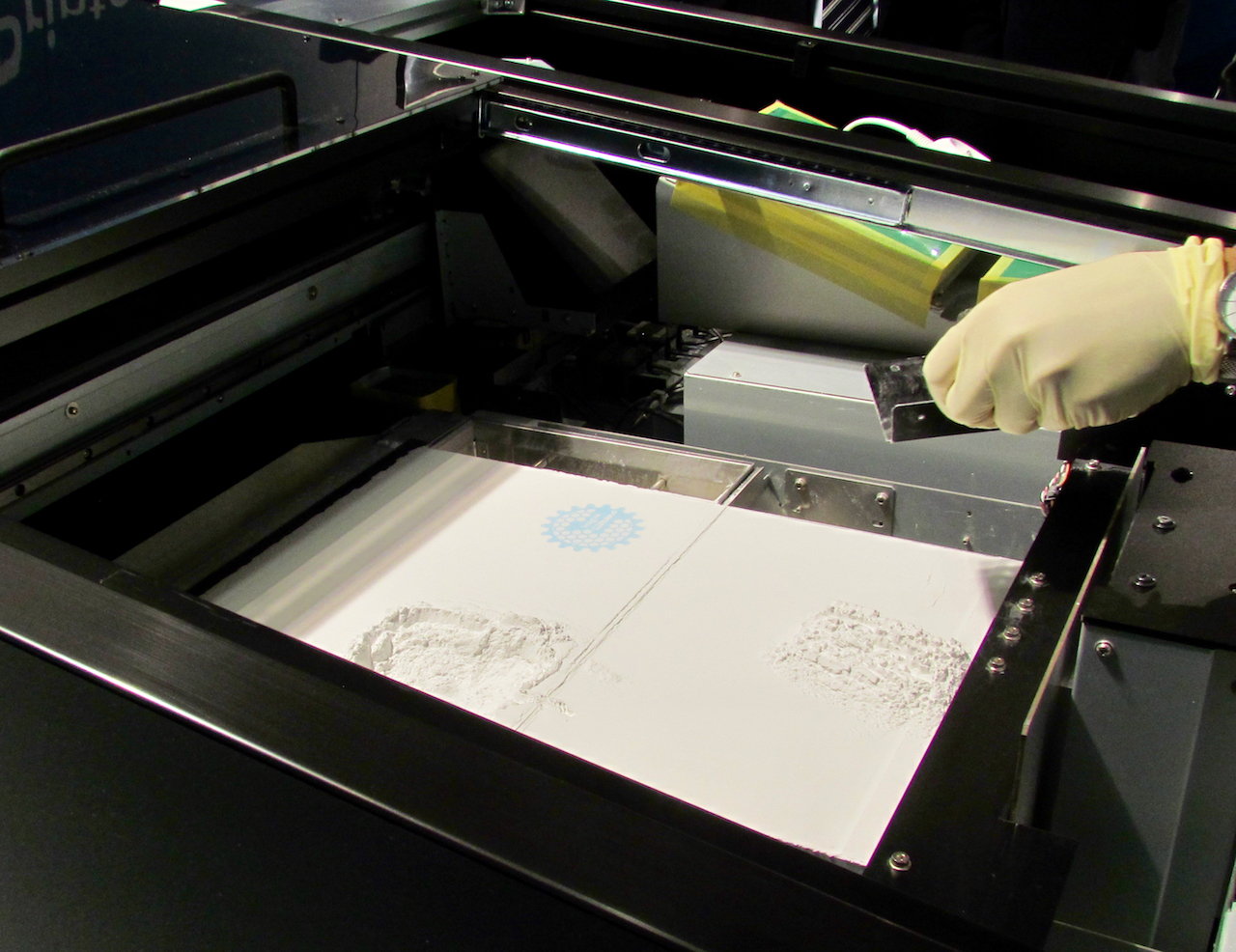

We were able to get a close look at a very curious machine under development by Roland: a large industrial-sized ceramic 3D printer.

It’s currently an unreleased product, and in fact actually has no product name as yet. But what I can tell you is that it’s a powder-based machine that uses a binder jetting process. Inkjet heads selectively squirt binder onto a flat bed of powder. The binder holds the “green” part into the desired shape, which then must be dried. Then it’s sintered to fuse the suspended powder into a truly solid object in a separate furnace.

But what kind of powder can be used? The company says the process works with ceramic (as shown in these images) and also aluminum and other metals. It’s a metal machine!

The plan is to release the machine in approximately 18 months after they work out some further details. The pricing is said to be “less than €50,000 (USD$53,000).

However, we asked about safety concerns, as most other metal 3D printing processes involving metal powder include significant safety systems because airborne metal powder is not only toxic, but frequently explosive! For this reason most powder-based metal 3D printers include atmospheric controls that evacuate oxygen during the printing process to avoid disaster. Typically Argon or Nitrogen is used to reduce the possibility of badness occurring.

But no such features were visible on the prototype Roland machine yet. I suppose we discovered what they will be working on for the next 18 months.

Via Roland