There is no shortage of resin-based 3D printers these days, and one new option is the atum3D.

Netherlands-based atum3D is new startup, only 18 months old at this point, but their machine is certainly powerful and suitable for many business uses. It’s positioned as a “small series production” system, and is entirely built by the company itself.

The company was founded by Tristam Budel, a long-standing experimenter in 3D printing technology, having required the technology for use in his workshop. Budel has published a series of Instructables related to high resolution 3D printing, and thus was well-positioned to launch a new product.

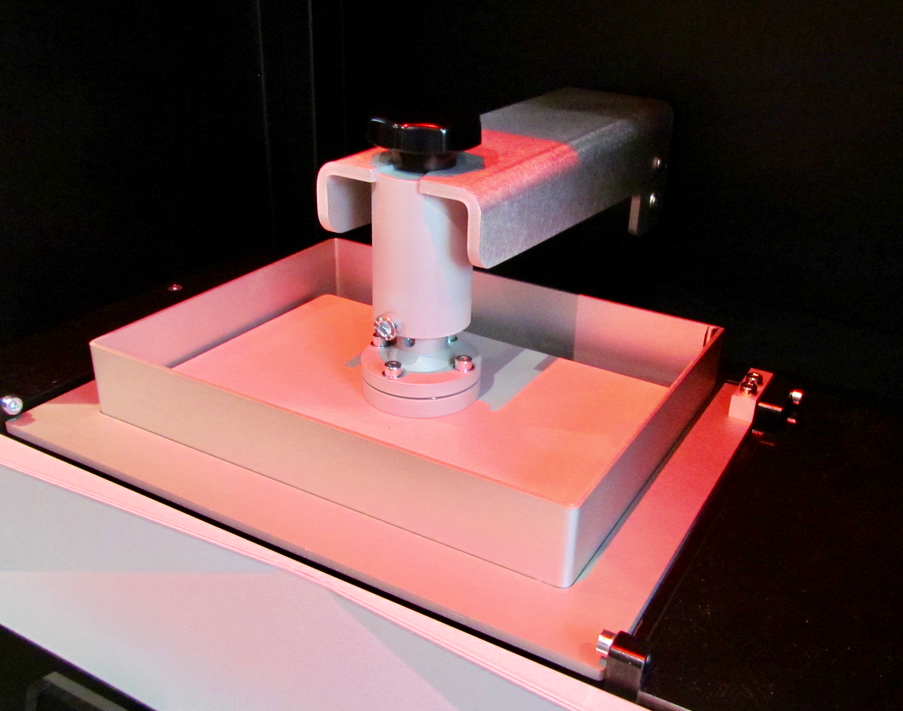

The DLP-powered resin machine is capable of producing high resolution 3D prints in a wide variety of plastic materials. atum3D does sell resins for use in their systems as a convenience, but they tout an open materials platform, where operators are free to use any resins available on the market. The company (correctly) believes production use will require many types of materials beyond that which they provide.

Where atum3D clients wish to use alternative materials, the company will provide a consulting service to assist in the tuning of the machine to ensure proper results.

The build volume of the atum3D DLP unit is 192 x 120 x 250mm, a reasonably healthy size for a DLP machine. atum3D’s Managing Director Tristam Budel explained that the atum3D is one of few DLP 3D printers that is entirely capable of 3D printing the FULL build volume as a solid block. Evidently this is not always possible. In fact, Budel explained to Fabbaloo that it’s possible to even go beyond the specification in the Z-axis and 3D print objects up to 300mm if absolutely required.

This unit is not one of the few speedy resin machines we’ve encountered lately, as it uses the standard “peel” process when printing each layer.

The atum3D DLP 3D printer is listed at €15,000 (USD$15,900) and thus places it among the market for commercial units.

I asked Budel how the company is funded, as it appears able to proceed, and was told their are a number of venture capitalists behind the company, providing them with the cash to get things started and grow.

Finally, I asked where the name “atum3D” came from. Budel explained it was concocted by his brother, who pointed out that it’s also the name of the ancient Egyptian goddess of Creation.

So, let’s Create!

Via atum3D