Metal 3D printing on the desktop is pretty much a dream for many designers due to the extreme cost involved, but soon there may be an option.

Ability3D is a startup company working on a hybrid CNC – metal 3D printer.

I’ve been skeptical of inexpensive metal 3D printing initiatives due to the safety and power constraints of the metal powder printing process, but it seems that Ability3D is doing something entirely different.

Instead of using a laser-fused powder process, which most metal 3D printer options use, they have a far simpler approach: they’ve essentially mounted a MIG welder as the “hot end” on this machine. The motion system then moves the “welder” around and deposits MIG wire material.

Now at this point you must be thinking, “but that would produce horribly inaccurate and sloppy prints” and you’d be right.

But here’s how Ability3D overcomes this: the machine also includes a simple CNC end mill that trims off the excess material – ON EACH LAYER!

Yes, this is quite a bit slower as the printing process is interrupted by milling activity, but the result is near perfect layers.

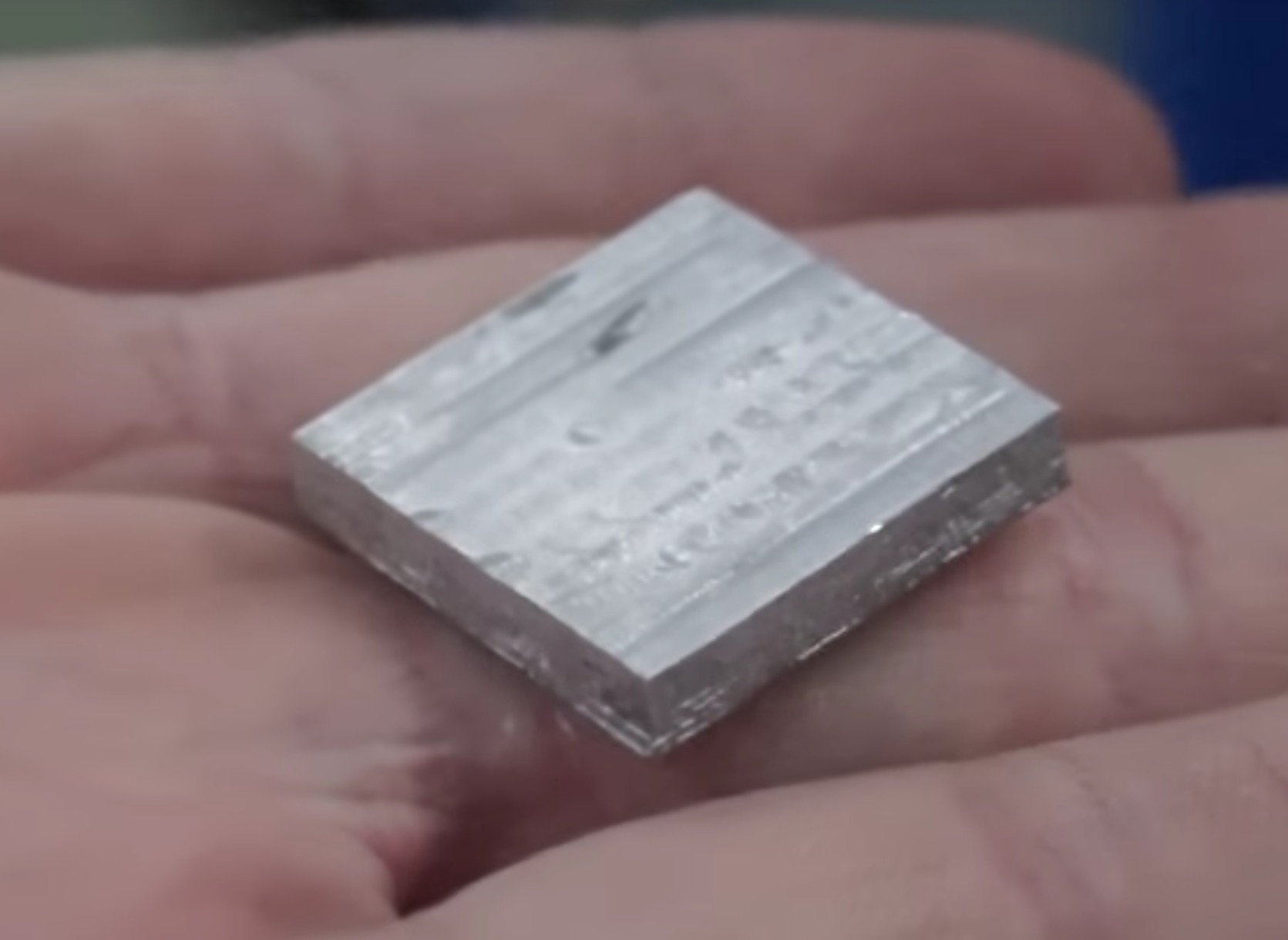

This hybrid of CNC and 3D printing is extremely interesting because it DOES NOT compromise the ability to 3D print arbitrary shapes that could not be handled by a CNC. The CNC is fully capable of accessing all parts of individual layers – AS THEY ARE PRINTED. The result is well formed, trimmed metal objects.

Can you get one of these? Well, not yet. According to Ben Willard of Ability3D, they will launch a crowdfunding campaign in January 2017, which isn’t that far away at all. Even better, they say the device will be for sale at around USD$3,000 each, vastly less than other metal 3D printing options.

And there’s even more: the CNC mill can be used for other purposes unrelated to 3D printing, such as milling wood or etching printed circuit boards. Lastly, you will also be able to obtain and install a plastic 3D printing extruder to replace the MIG head if you want to 3D print plastic.

I suspect this will be a rather popular machine.

Until January!

Via Ability3D