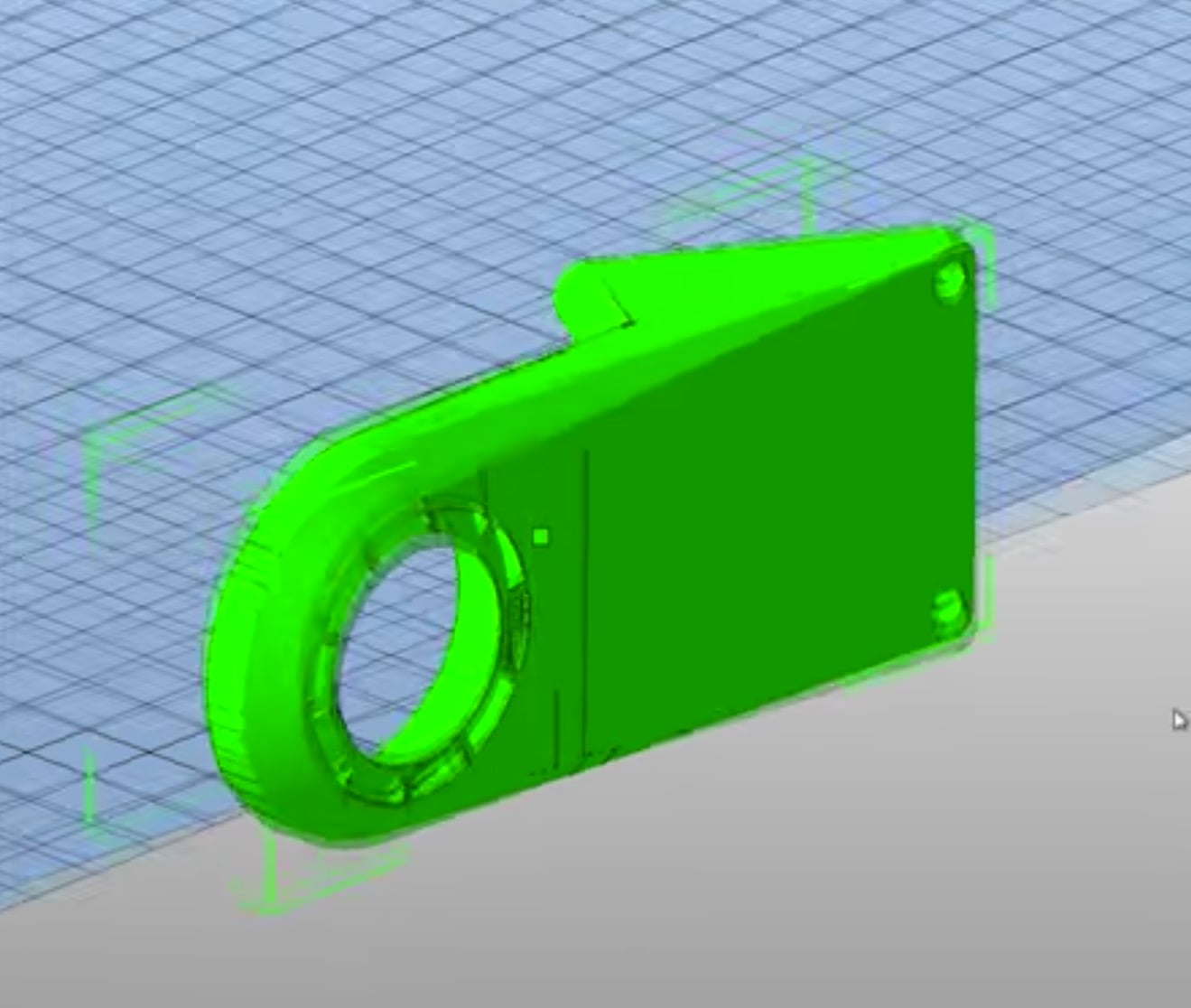

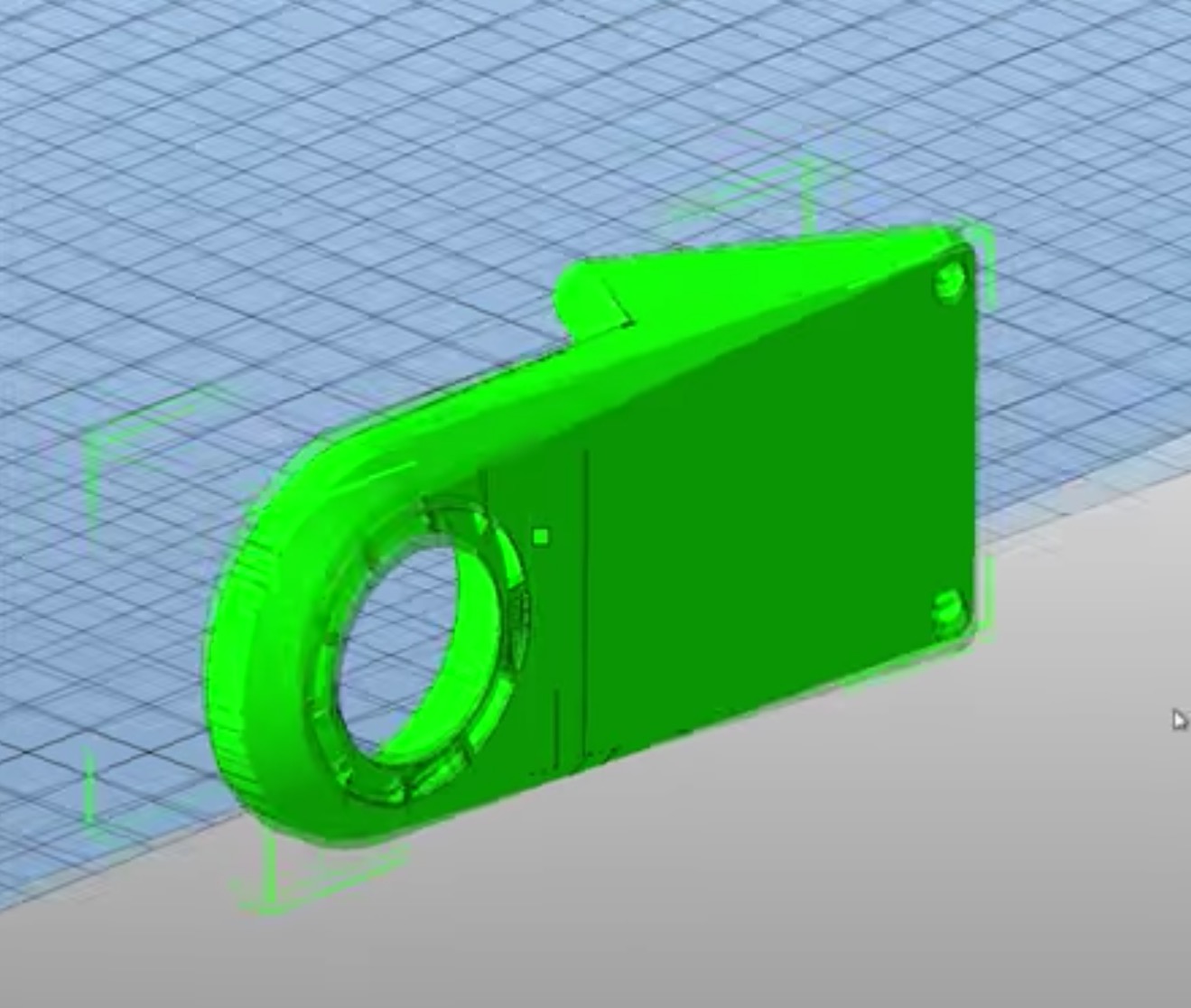

Have you ever had a “bad” STL file? I certainly have. Fixing them is often a tricky business.

The root cause of STL issues is that the file format itself is poor in that it makes it possible to define an invalid file. Yes, the format can work, but it also can validly define an invalid shape. That won’t change until we switch to a better file format to describe our 3D objects.

In the meantime we’re mostly stuck with STL files, particularly when loading a file from a 3D repository that doesn’t do print-quality checking.

In many cases you must somehow repair the STL file before presenting it to your 3D print slicing software. If you don’t it’s possible to confuse the slicer in such a way that the slicer – or even the print itself – could fail miserably.

Enter STL repair tools, of which there are several.

But there is a phenomenon I often encounter with such tools: they only fix “so much”. Often you may find SOME of the issues are resolved with a repair tool, but not all of them.

This is because different repair systems use different algorithms and approaches to detect and perform repairs.

And that’s often a solution: a problem missed by one repair tool may be found with another repair tool. The solution is to use multiple tools for repairing a wonky 3D model. Run it though one, then another, and even repeat. It’s possible to gradually resolve the errors until you have a truly correct 3D model.

There’s a great video that shows how this can be done using two popular 3D model repair tools, Netfabb Basic (now Netfabb Free) and MakePrintable, a web-based STL repair tool:

And this approach can be used with any combination of repair tools.

Don’t let those broken STL files win!