An unusual use of 3D printing has enabled far more powerful control over acoustic waves.

The medical industry makes extensive use of acoustical wave technology, most well-known through the popular ultrasound machines that can peer inside a living being by using sound reflections. It’s a great advantage over invasive techniques that damage the patient.

It would be a considerable advantage to use such noninvasive techniques for additional purposes, but that’s not currently possible because the technology used to generate the acoustic waves is rather blunt.

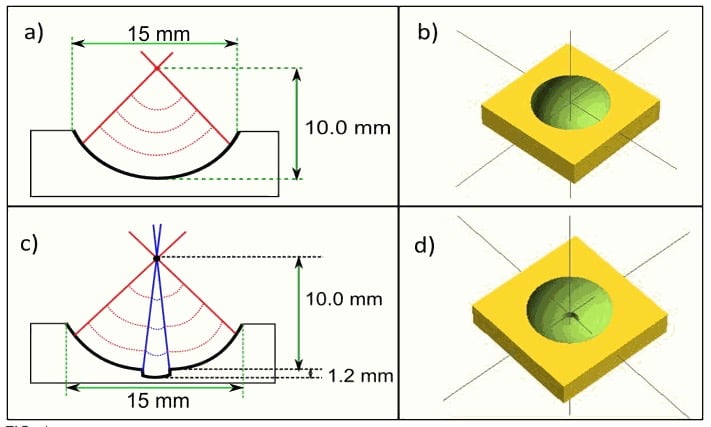

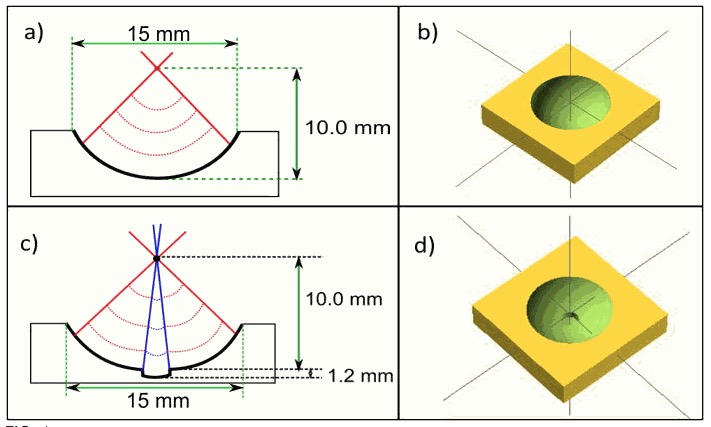

Today the waves are created using a negative glass lens covered with a layer of carbon nanotubes. A brief laser pulse hits the glass, causing the nanotubes to vibrate appropriately. The shape of the glass lens focuses the generated acoustic wave towards the target.

However, it turns out these glass lenses are extremely limited in shape, due to the methods of making them.

Researchers in Singapore have developed a new technique for producing these lenses using 3D printing.

Their process is to 3D print a lens shape using a high resolution resin-based 3D printer. The nanotubes are then applied to the new 3D printed lens using a cold process (as the glass nanotube process requires high heat) to keep the lens from melting. In this way they can produce lenses of arbitrary shape, enabling the generation of arbitrary shape acoustical waves.

Now to demonstrate how powerful this could be you must realize that this approach enables the creation of finely focused small waves, perhaps suitable for non-invasive surgical approaches.

There’s much work to be done on this approach, but it certainly sounds very promising.

Via Scitation