I’ve encountered Italy-based Sharebot on many occasions over the past few years, but I noticed something very interesting the last time we met.

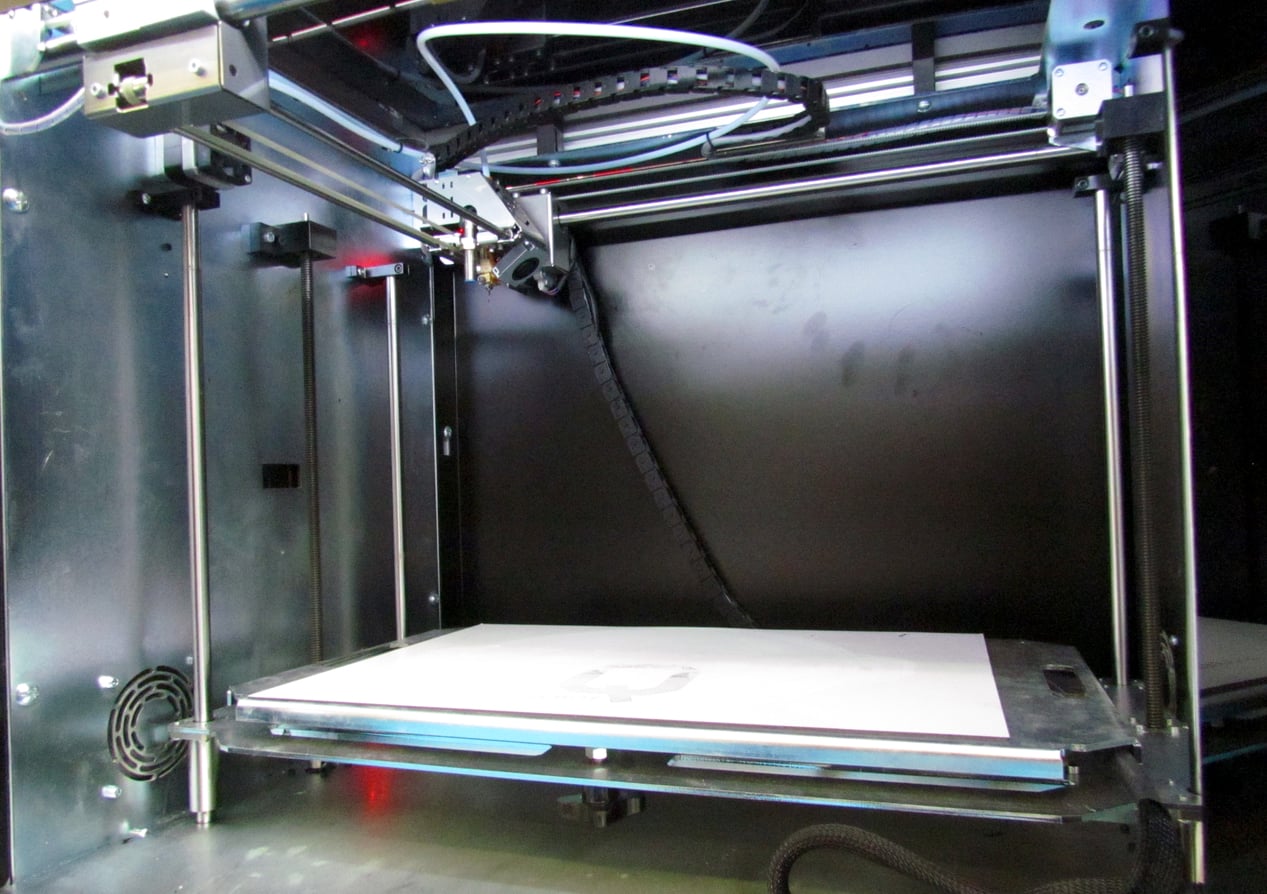

The company has been around for at least 4 years, launching with a conventional extrusion-based desktop 3D printer as so many other companies have done. Since that time they’ve increased the capabilities of their technology and provided a number of variations, including this unique ultra-wide desktop unit, the XXL.

I managed to see up close several of their latest units.

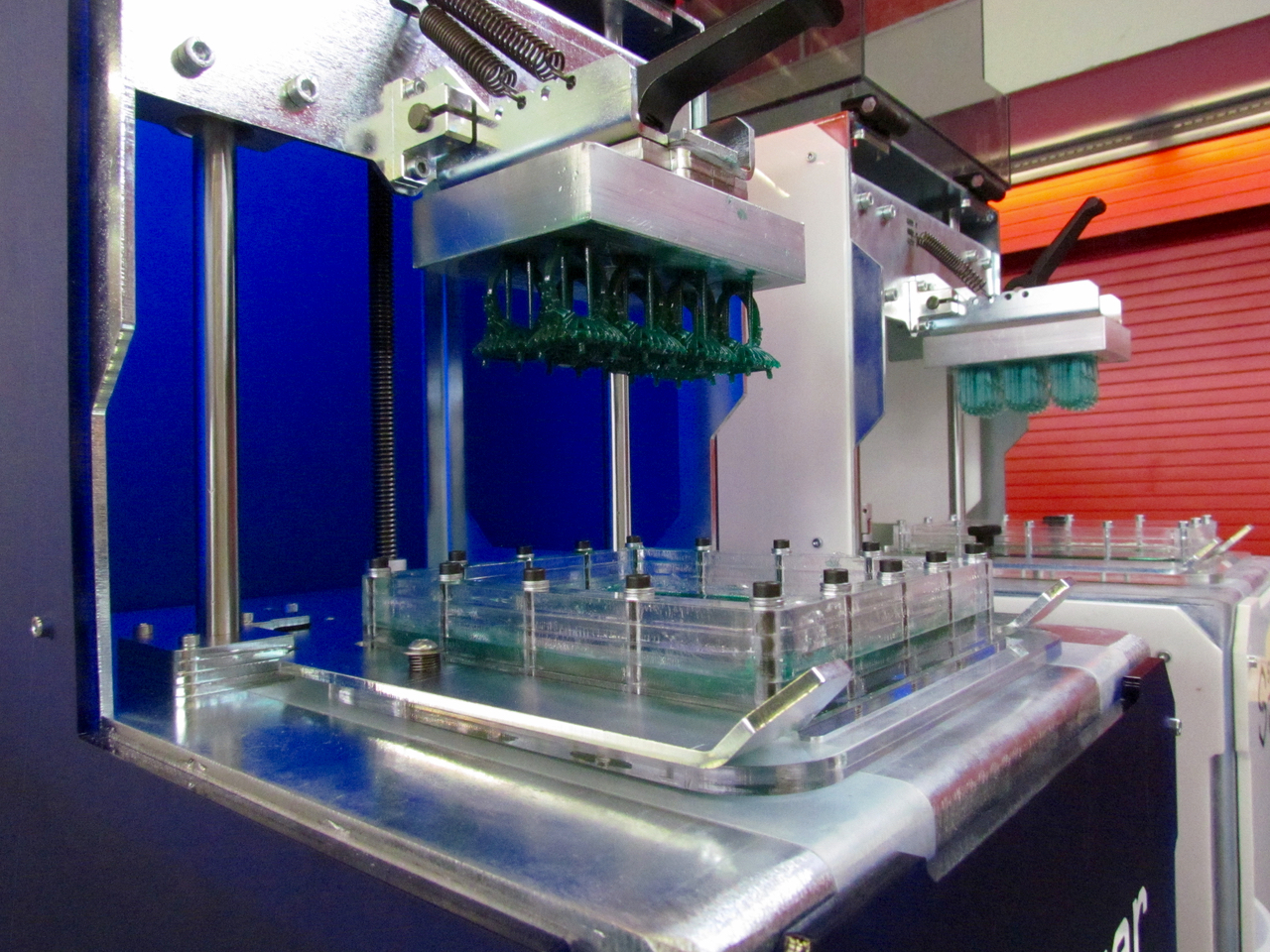

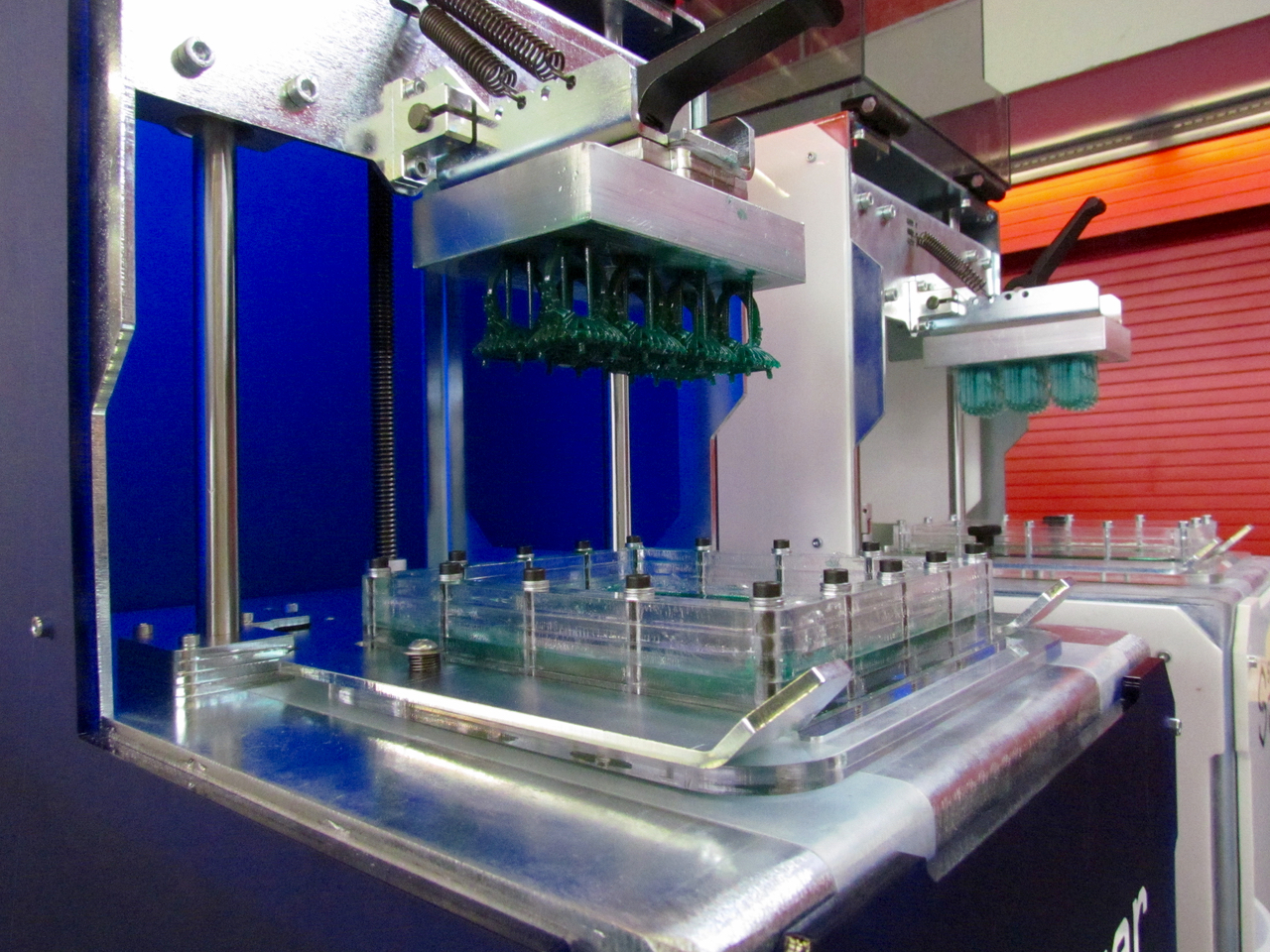

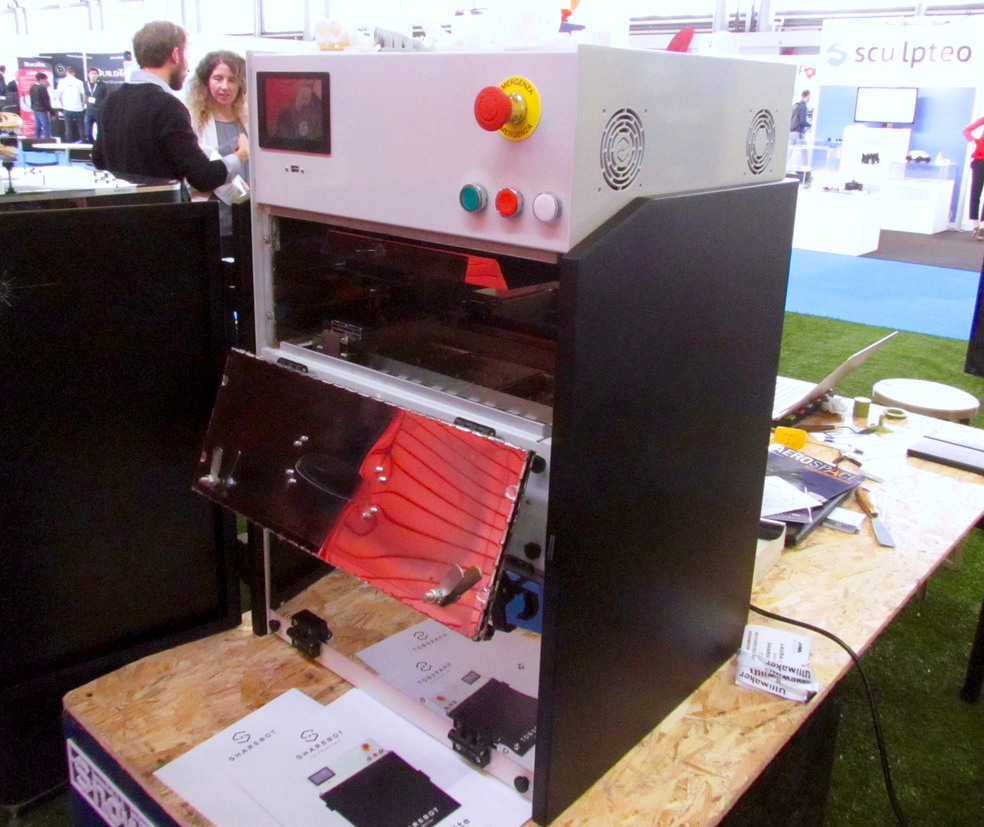

This is the Sharebot Voyager Warp, a resin-based 3D printer. It’s called the “Warp” due to it’s rather dramatic speed of printing.

The Warp is one of several resin machines that have solved the “sticking” problem that slows most resin equipment. They’ve coated the resin tank with a special material that prevents fused resin from bonding to the tank. In other machines, this necessitates a slow “peeling” process to separate the two. Meanwhile, the Warp has no requirement for this and can 3D print quickly, as fast as the resin can fuse.

But it does this very fast, because it uses an LED system to illuminate an entire layer (the resin surface) at once. So you have a speed up by doing the whole layer simultaneously – and a speed up from avoiding the peel process.

We were told the Warp can, for example, 3D print a dozen jewelry rings in only 15-18 minutes! The specs say “100mm/hr”. That’s pretty fast. Here’s a video showing the speed:

The LED light source is also far more reliable than other units that employ conventional projectors using bulbs. Bulbs burn out; LEDs last far longer.

The Voyager Warp is designed for professional use and can use a variety of resins – including castable resin. It’s priced at around €20,000 (USD$22,500).

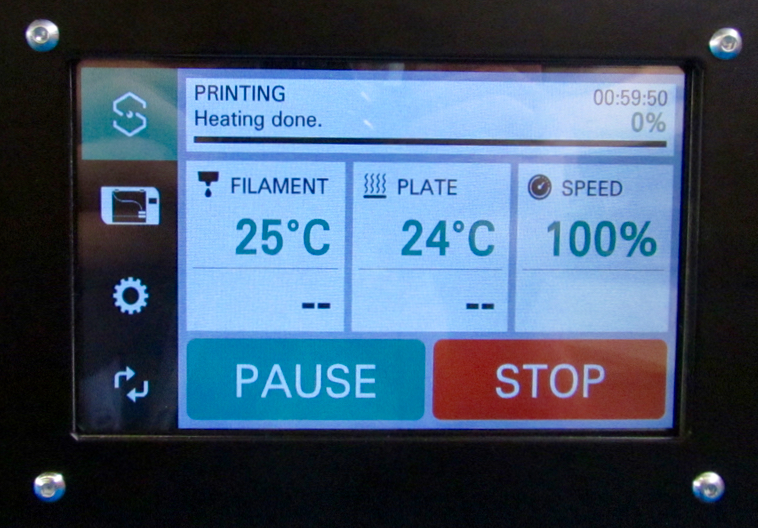

The latest iteration of their plastic extrusion technology is in the “Q”, which includes a very healthy build volume of 297 x 420 x 300mm and an automated calibration system for ease of use.

The Q is highly networked and includes a means to monitor and control the device remotely from most common computer platforms. There’s a webcam to enable visual monitoring as well. There’s a filament “out” detector that can pause printing operations and warn the operator remotely.

To assist with larger print operations, the Q includes the ability to handle plastic filament spools up to 2.2kg in size. It also includes a storage cabinet at the bottom for additional spools and tools. It includes interchangeable nozzles to enable fast – or fine – 3D printing. It’s priced at €9,000 (USD$10,000).

There’s also the large Andromeda machine, which is a much larger resin machine, having a build volume of 250 x 250 x 250mm. It’s not a “whole layer” printer like the Voyager, as it uses a laser. However, the resolution is quite good because Sharebot has ensured the diameter of the laser – and thus the minimum feature size that can be fused – is as small as 0.030mm.

The Andromeda is priced at €35,000 (USD$39,000).

And then there’s the SnowWhite, a powder-based 3D printer, which uses a laser to selectively fuse thermoplastic powders. The build volume isn’t particularly large at 100 x 100 x 130mm, but the technology permits printing of very complex objects without concern for fragile support structures: support is provided by unfused powder adjacent to the printed model.

The SnowWhite can 3D print in a variety of powders, including nylon and flexible materials.

The print quality is quite good as you can see here.

And here.

What got me about all this is the sheer size of their product line. This is a company that started with simple plastic extrusion, yet somehow has now developed multiple lines of 3D printers using several different 3D printing processes: extrusion, powder and resin. Even better, these machines are all notable in specific ways that may meet user requirements. Impressive!

Start small, but become big.

Via Sharebot