TU Delft researchers have combined two 3D printing techniques together to demonstrate a powerful new process.

The problem they’re attacking is the ability to create highly complex structures suitable for medical implant purposes. It turns out that many such bioprinted implants require highly detailed surface patterns that are compatible with biological processes.

While nano-printers can produce the required patterns, they can typically do so only on flat surfaces, which greatly limits the their utility in bio-scenarios.

But wait – there’s another process researchers have previously developed: 4D materials, or materials that can change shape after printing.

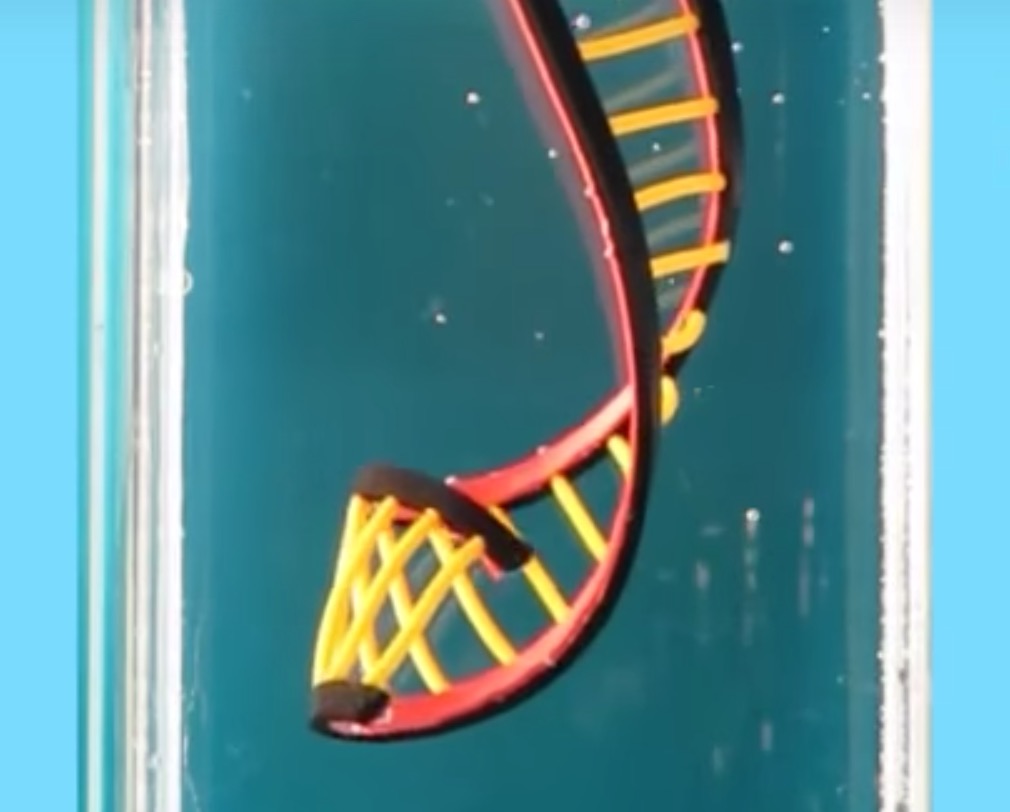

This is what the TU Delft researchers did: combine the two to enable production of complex structures with the appropriate surface patterns. Print the flat structure with patterns, then “activate” it after printing to reform its shape into the desired final object, using a variety of external stimulus, including temperature changes, etc.

To do this they’ve used layers of shape memory polymer and hyperelastic polymers to create structures that reform in predictable ways. Specifically, they have currently four motion paradigms:

- self-rolling

- self-twisting (self-helixing)

- combined self-rolling and self-wrinkling

- and wave-like strips

By using appropriately sequenced sets of these movements, they can twist flat 3D prints into desired shapes. Watch this video to see how a flat structure can become a twisted DNA-style shape:

While this seems to be an important step in bio printing, I’m wondering where else in 3D printing this technique might apply.

Via PhysOrg