The new Mark X from Markforged includes a unique and very necessary feature.

Markforged has been making interesting 3D printers for a few years now, focusing on professional use and in particular enabling the production of very strong parts through the use of nylon and embedded carbon fiber segments. Their well-received previous generation machine, the Mark Two was a bit of a revelation, as it employed a cloud-based system to enable the otherwise complex business of properly embedding carbon fiber.

Now they’ve announced a significant new product based on the Mark Two: the Mark X. Visually it looks similar to the Mark Two, aside from the lower cabinet, but there’s a lot more to this machine.

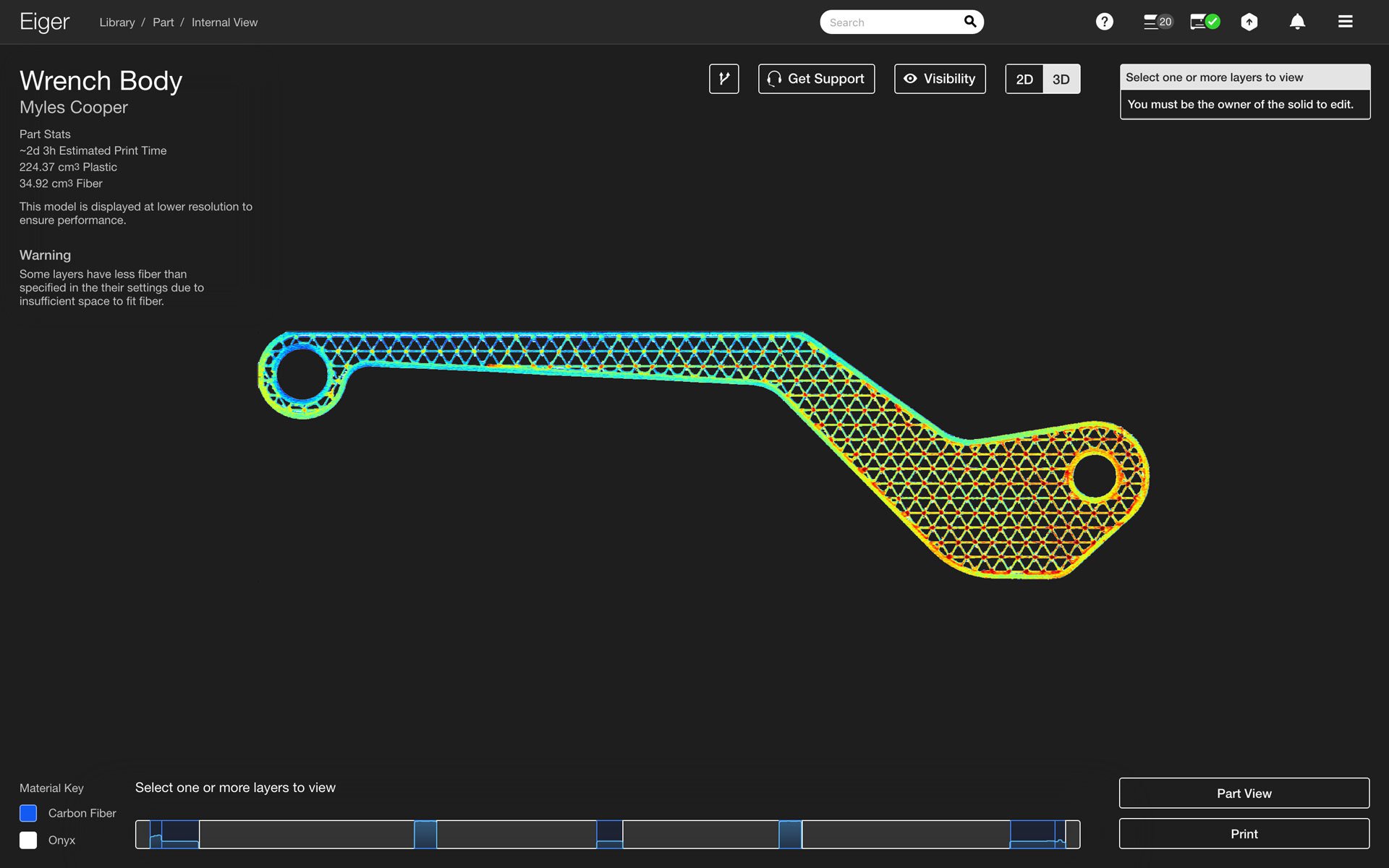

It is, of course, a 3D printer. The Mark X can print in nylon, as its predecessor could, but it also uses something called “Onyx”. It’s a proprietary material developed by Markforged that’s an extremely strong substance made by combining nylon and micro-carbon fibers. They describe it as “not only tougher than other 3D printing plastics— it’s also stiffer, more heat tolerant, and more dimensionally stable.”

The Mark X can also 3D print in their normal Carbon Fiber, as well as variations of fiberglass and kevlar.

Resolution is quite good on the Mark X, as it can drop 0.05mm layers in its vast 330 x 250 x 200mm build volume. I’d like to note that unlike most other 3D printer vendors that offer more-or-less uniform cubic or tall oriented build volumes, Markforged uses wide build volumes that are likely more suitable for the production of strong parts, where you can lay down continuous lines of carbon fiber.

But those are not “the” key feature of the Mark X.

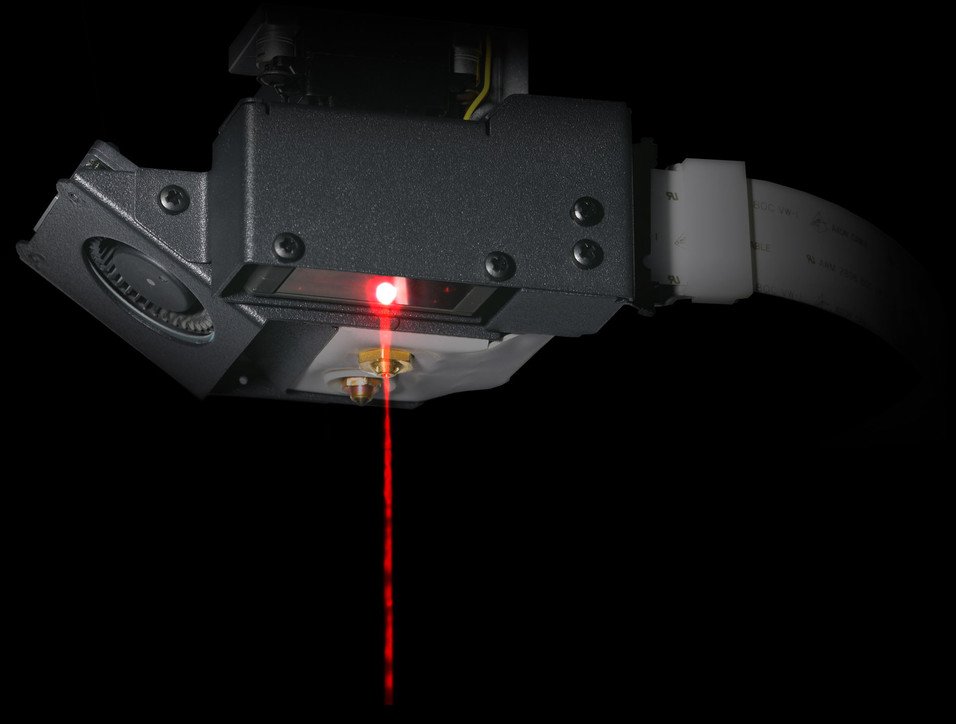

The key feature is the ability to check the correctness of printed parts with an onboard precision laser inspection system!

The laser system works in concert with their cloud printer management system to match the desired 3D model with the print. It will measure the exterior dimensions of the print and ensure they are within desired tolerances as compared to the original 3D model – while the print takes place!

This feature enables you to print production parts on the Mark X! They explain how it works:

Define a tolerance specification in Eiger, our cloud based 3D printing software, and the Mark X will scan your part while it’s printing to ensure that it always meets the spec. If an error is detected you will be alerted and can choose to cancel the print remotely, saving time and material.

I don’t know of any other machine that combines the ability to produce extremely strong parts – and ensure they are correct at the same time.

The Mark X appears to be available now, but for pricing you’ll have to contact Markforged for a quote. That usually means it carries a higher price, but with these features, the machine deserves it.

Via Markforged