This month’s community support selection is the RMADS project undertaken by researchers at Newcastle University.

Each month Fabbaloo selects a worthy non-profit project or activity contributing to 3D printing and provides not only a published story on the project, but also free advertising on our well-read pages. If your project would like to take part in the program, please fill out our application form here.

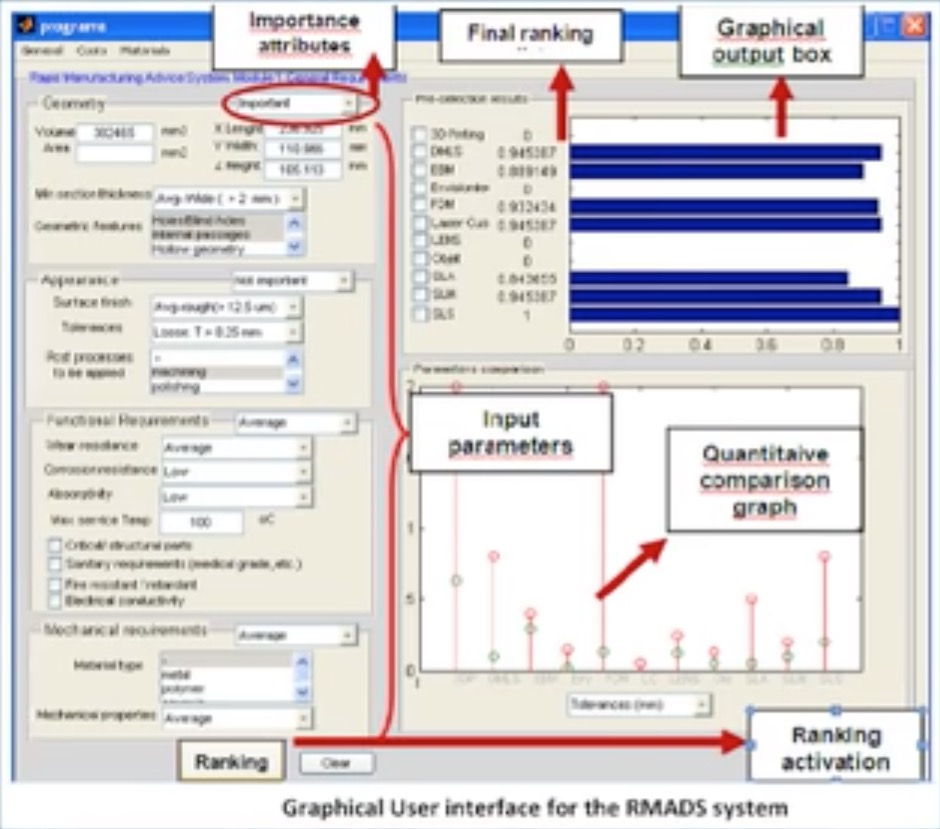

RMADS is an open source project that I believe could become quite valuable to current and future users of advanced 3D print technology: it provides advice to assist the selection of equipment and materials.

Dr. Javier Munguia of Newcastle University’s School of Mechanical and Systems Engineering explains:

This is an open-license 3D Printing Selector which has just been released of Github and allows users to either run the full app in compatible Matlab versions, or extract the system’s logic and use it with the programming language of their choice.

We have developed Custom-made standalone versions for industrial users who want to evaluate 3D printing capabilities for their industries and they can do so by running a part-by-part assessment.

The system is comprised of 3 modules: 1) General requirements, 2) Materials, 3) Costs and each of these modules is linked to a 3D printers and Materials database. These databases are the key and we suggest users to update it according to their needs. For instance, it makes no sense for heavy machinery manufacturers to have PLA and Ninjaflex as alternatives, but it makes all the sense for the footwear sector!

So it’s all about choices.

It’s a different type of system that provides advice to explore 3D printing alternatives. When we started developing it we used to define it as an “Expert system”, as it has different artificial intelligence tools embedded in the code. However with the recent advances in artificial intelligence & machine learning (e.g. IBM’s Watson) we decided to be less pretentious about it.

If you are a machinery developer and you want to analyse the feasibility of 3D printing a number of metallic components in series of ONE, or in small series, then you can run a RMADS session and get some ballpark figures.

There are other great solutions out there like SENVOL, that actually offers a huge updated database, and they do a great job providing consultancy; or Granta Edupack which we use –by the way- here in the University to select materials for engineering designs. However systems like RMADS are aiming at providing a straightforward assessment of 3D printing suitability based on the built-in logic.

Ultimately, we would envisage such a tool as a standard add-on to common CAD suites.

Require some assistance configuring a 3D print operation? You may want to check out RMADS and adapt the code for your own applications.

Via RMADS