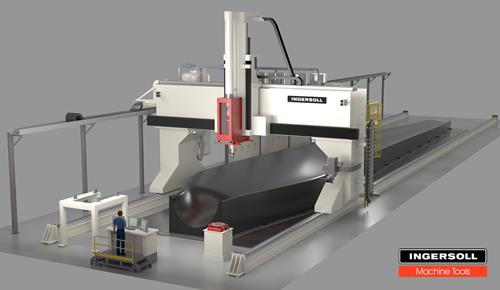

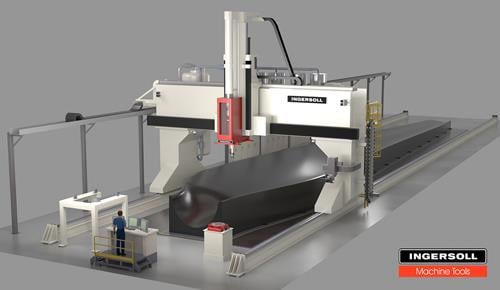

Ingersoll Machine Tools announced plans to develop a massive 3D printer in association with the US Oak Ridge National Laboratory.

This machine uses the well-known plastic extrusion technology originally developed by Stratasys decades ago – but now the patent has long expired, leading first to the explosion of inexpensive desktop 3D printers, and companies like MakerBot and Ultimaker.

But evidently the patent expiry has also unleashed a series of incredibly large 3D printers.

The Ingersoll machine is to have a build volume of approximately 7 x 3 x 14m. Wait – that’s fourteen meters long!

As you might imagine, the build time for such a massive volume would be endless, but apparently that’s not the case as the machine will be able to deposit an astonishing 453kg of material per HOUR.

The machine is named, “Wide and High Additive Manufacturing”, or “WHAM”. Appropriate, yes?

However, this is not yet an actual machine – it’s merely a concept that will require considerable development. While the mechanical portions of the machine are a challenge likely easily met, I suspect the big deal will be materials. Printing at such a size may require considerable effort to identify a composite mix that not only offers desirable end-user properties, but also enables reliable 3D printing. For example, it should not warp – print failures at that size could be financially catastrophic.

Via Composites World