Recently we examined machines from Deltatower, a Swiss-based manufacturer of large-sized delta 3D printers.

We’ve seen machines from this company previously, but now they’re quite a bit larger and more sophisticated.

Currently the company offers a number of machine sizes, ranging in build width from 445 – 900mm and height from 580 – 1200mm. That’s quite large.

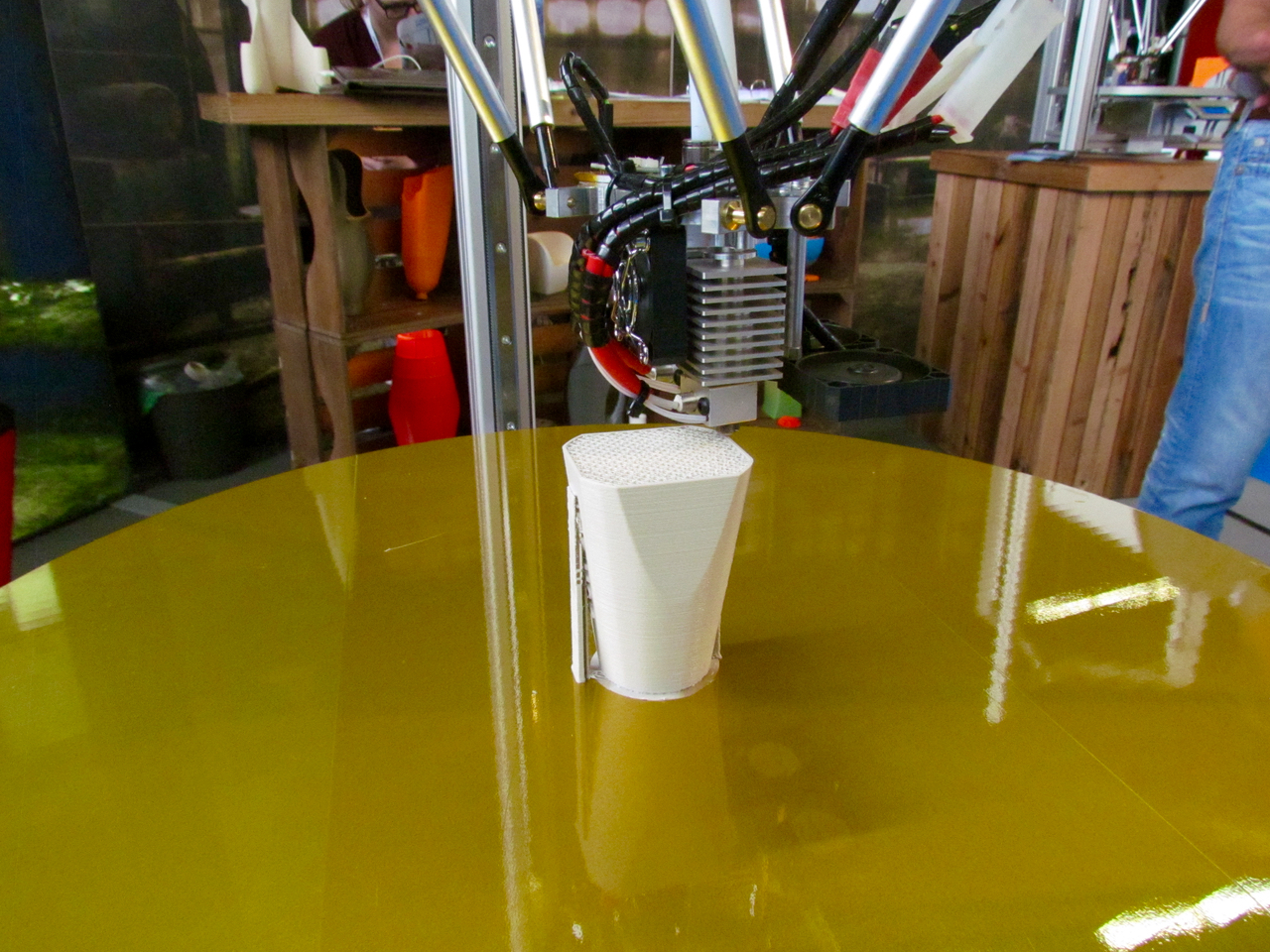

One of their machine is shown here, and as you can tell, it’s very tall.

These machines are said to be of “industrial quality” and include the normal features one might expect. However, there are two interesting innovations I want to mention.

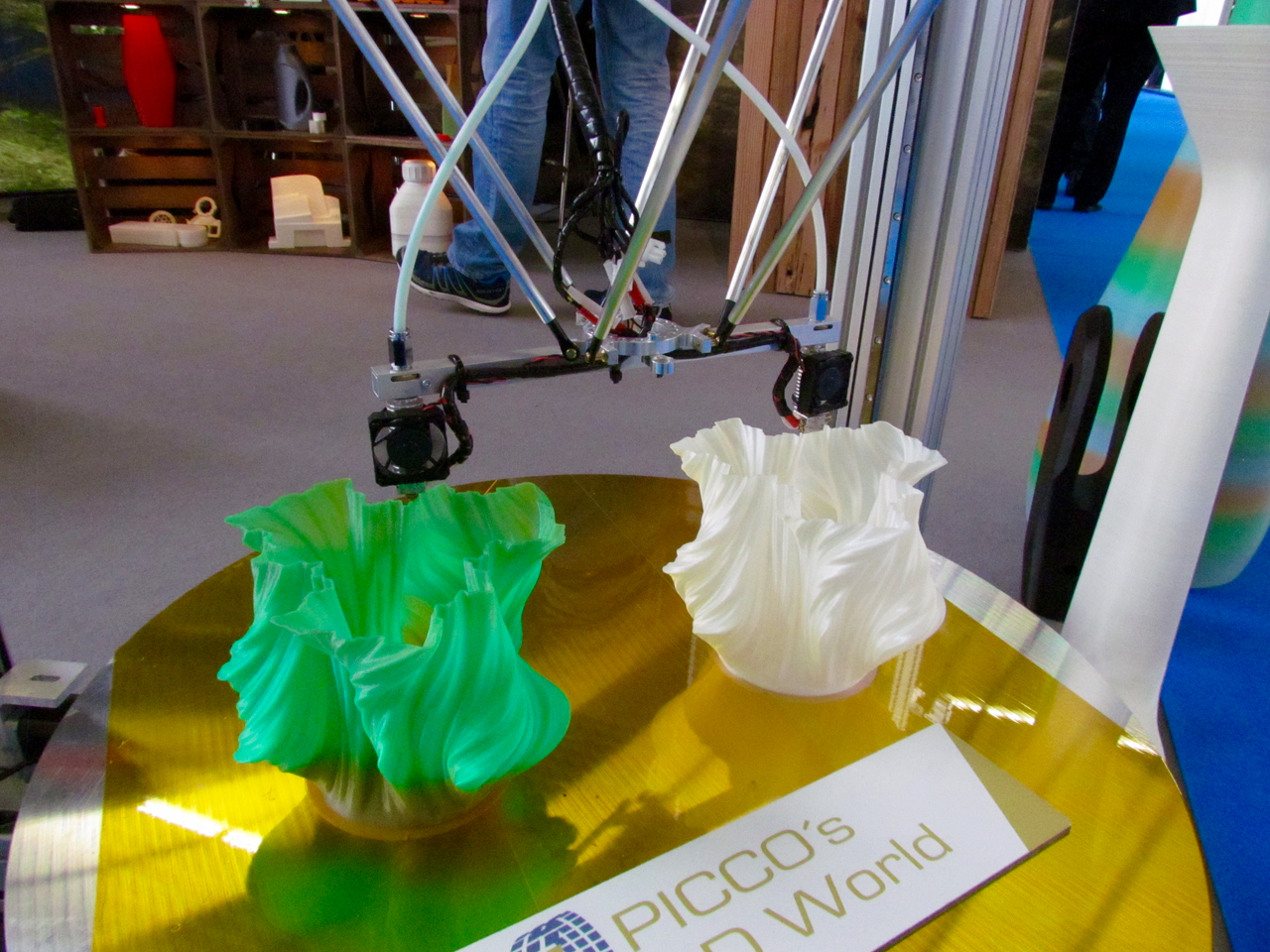

The first is what they call the “multiplex print”. This feature involves a second hotend and extruder installed on the larger machines. This enables printing two copies of the same object simultaneously, and each can be made from different filament.

While the image shows two heads, it’s apparently possible to install a third and essentially triple the throughput of the machine, if you’re interested in making multiple copies of tall objects in PLA or PETG plastics.

The multiplex option is available on the RTA700 model for €25,900 (USD$29,000).

The second interesting innovation is the “matrix nozzle”. They explain it as follows:

Large print rooms allow printing of massive objects. Massive objects require massive print nozzles. This is why Deltatower developed the matrix nozzle. Consisting of seven drill holes with optimised internal and external geometry, the matrix nozzle allows higher flow rates. Large objects can be printed in shorter time and with higher wall thickness.

It sounds like a more sophisticated hot end that can print more material faster, like a wide nozzle, but more effective. I have not seen this approach on other 3D printers, delta-style or not.

It’s always interesting to see unique innovations appearing from smaller vendors. It’s their ingenuity that pushes the industry forward.

Via Deltatower