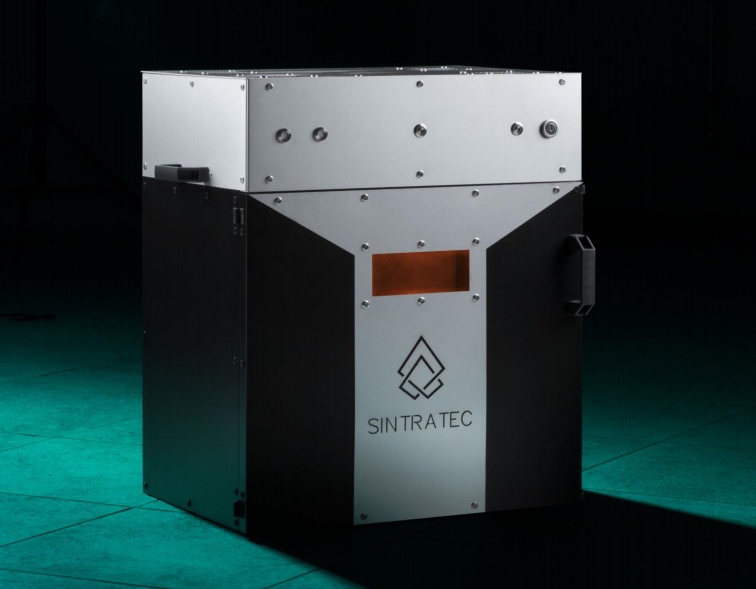

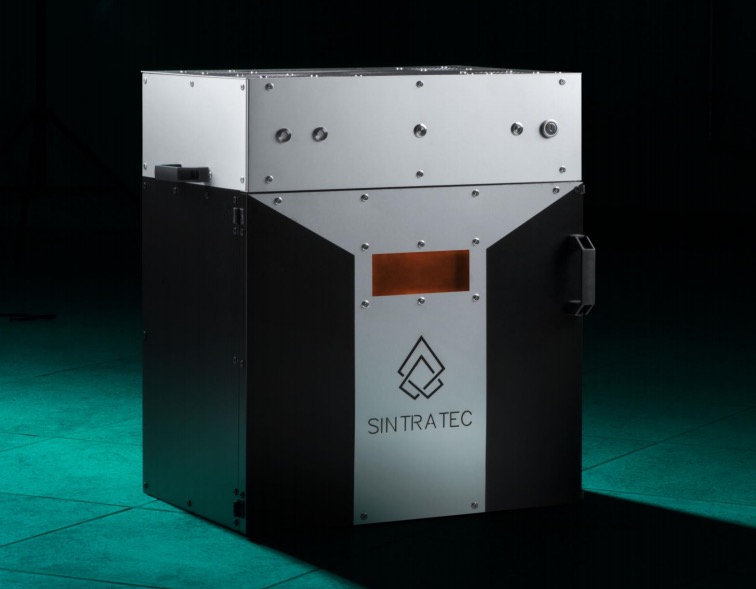

If you’re seeking a way to 3D print complex structures in nylon, there are a few choices, but one of the least expensive is Sintratec’s 3D printer kit.

Nylon is an ideal material to 3D print as it produces relatively strong objects compared to more commonly used materials. You can 3D print nylon filament on suitably equipped extrusion 3D printers, but the results are not quite as good as you’ll receive from the expensive industrial nylon powder-based machines due to the nature of the laser sintering process.

In this process, a flat bed of uniformly sized nylon particles are selectively sintered by a moving laser beam. Another layer of powder is added and the process repeats, gradually building up an object that can be extracted from the powder when complete.

The catch is that those industrial machines can be quite pricey, often exceeding six figures in cost. Of course, you can use public 3D print services to produce small numbers of high quality nylon prints, but the per-print is the most expensive you’ll encounter. If you need to print many parts, it might be less expensive to get your own machine if it costs as low as Sintratec’s kit option.

The Sintratec Kit offers a powder-based nylon laser sintering 3D printing capability, with a build volume of up to 130 x 130 x 130mm (although strangely they recommend using only 110 x 110 x 110mm for some reason).

Resolution is stated as 0.100 to 0.150mm, which might not sound terrific when compared to some inexpensive plastic extrusion machines, but the laser sintering process makes the surface smoother than you’d expect. Think smooth surfaces, but not extreme detail.

Print speed is notable: the Sintratec Kit can print up to 20mm per hour over the entire build volume – it’s less dependent on the object’s complexity. For higher resolutions, the speed can drop by half, but still is respectable. The game here is to fill up the build volume with as many objects as can fit and print them all at once.

The powder approach means you can attempt to print very complex structures without concerns for support material: the unsintered powder serves as support. You simply lift the print out of the powder when completed, dust off the residual powder and you have a completed nylon print.

Software for Windows (only) is provided with the Sintratec Kit, and has been developed specifically for this machine.

This product is a kit, and it’s a fairly complex machine to put together. The company says it should the around four days to build the 29kg machine, and they provide extensive online documentation to ensure you do so correctly.

Print material for the Sintratec Kit is of course powder, which is sold by the company. You can also experiment with any sinterable 3D print plastic powder, but not metal powder as the machine is not sufficiently powerful to melt metal.

The company currently offers a black polyamide 12 material that is composed of 0.06mm particles. It’s sold in 2L bottles that sell for €149 (USD$168). That’s a bit more than 3D printer filament, but not bad for powder pricing.

There’s one concern that should be accounted for before purchase of the Sintratec Kit: powder handling. Operating this machine will certainly generate powder spills from time to time, and some of the powder could become airborne. Therefore, you should install the machine only in an area that can withstand this effect. You should also strongly consider wearing air safety apparatus when working with the machine, particularly when loading powder and removing completed prints.

Pricing of the Sintratec Kit is quite reasonable for a machine of this capability: €4,999 (USD$5,650). This makes the machine a very good option for educational institutions or even makerspaces looking for a powerful 3D printer that can do things typical machines cannot.

Via Sintratec