I’ve been thinking more about the implications of Stratasys’ industrial 3D printing announcement last week.

To recap, the company revealed a startlingly deep development relationship with two industries, aerospace and automotive, and at the same time appeared to shift towards production manufacturing of 3D printing.

As part of the announcement, two demonstration technologies were unveiled: an 8-axis robotic 3D printer capable of efficiently 3D printing composite materials without the need for support material, and a second machine that prints sideways to enable production of infinitely-long models. Yes, infinite, so long as you keep supplying material to the device. Please read our details here, here and here.

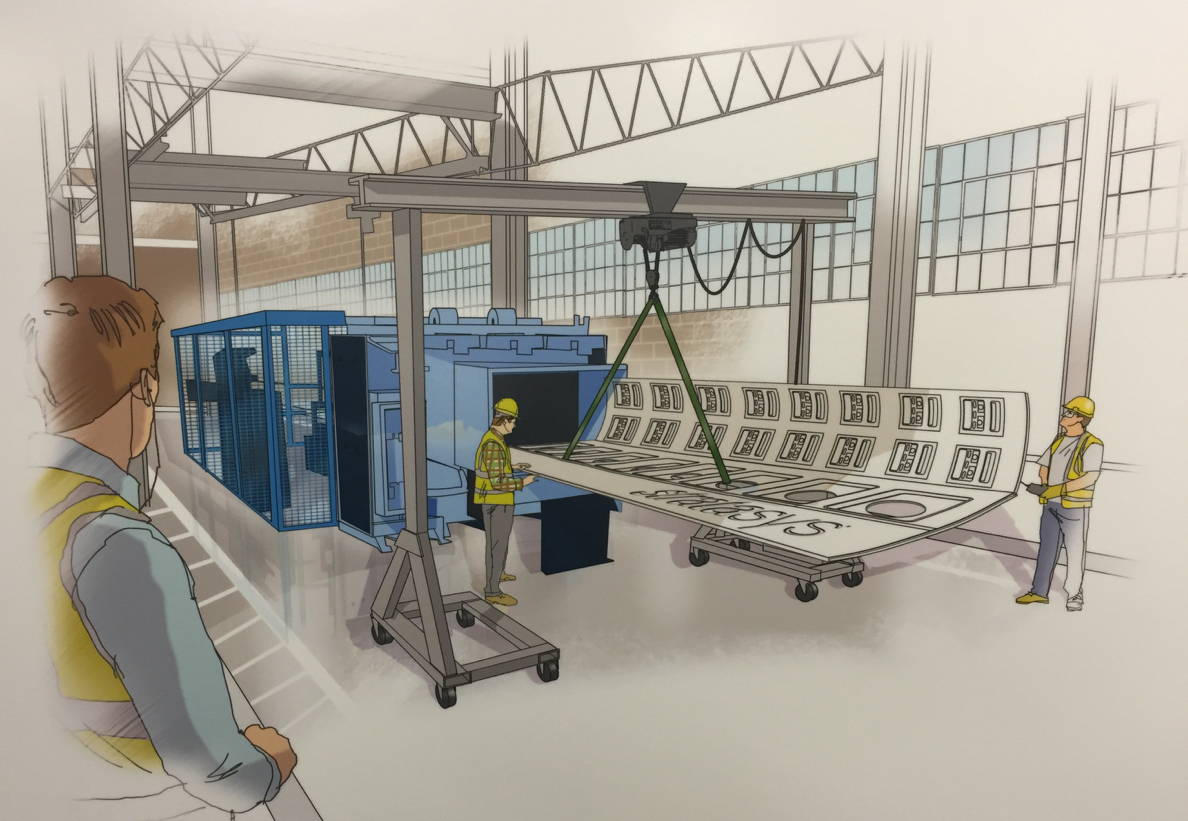

Size: The machine concepts announced had one common element: size. While I was not presented with machine specifications (which makes sense because they are “concepts”, not “products”), it was very clear these machines are able to produce very large objects, and in the case of the Infinite Build demonstrator, extremely large.

This size is a big deal because it opens up the possibility of using 3D printing for an entirely new class of problems that previously were unable to fit into existing 3D print technologies. Thus, industries like aerospace and automotive will be able to produce jigs, fixtures and even end-use parts at the full scale they are used in actual products.

Stratasys seems to also understand that the cost of 3D printing has also been a barrier to usage, and the move to pellet-based material may assist the change to 3D printing technology.

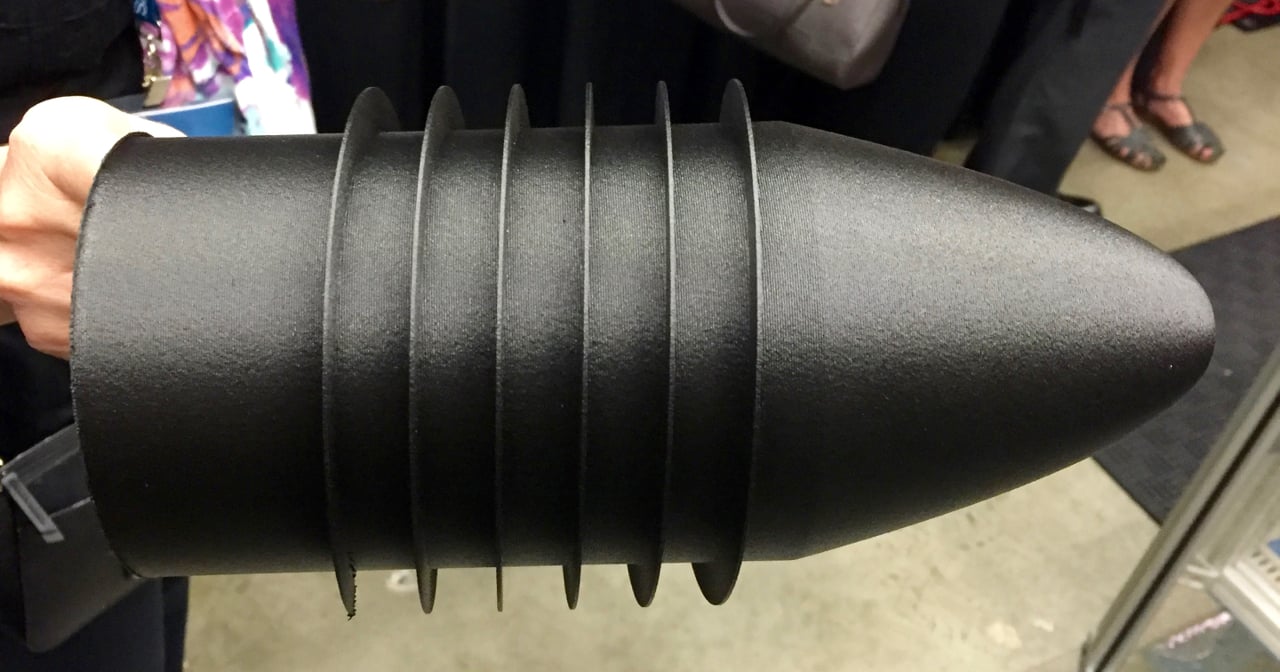

Speed: The two demonstrator concepts had another feature in common: speed. These machines were able to produce objects quite quickly, such as this composite component, made in about an hour. Doing so on other machines could be quite challenging in that short a time.

Speed is critical if you are 3D printing large objects. If typical 3D printing speeds were used on these industrial concepts, operators would have to wait weeks to receive a completed print. Not so with these speedy technologies.

Production: Up to now 3D printing has largely been used for prototyping rather than producing end-use parts. Although Stratasys themselves have made noise about making production parts, the manner of doing so was quite limited due to cost, size and material constraints.

Those barriers appear to be been at least partially resolved with the new machine concepts, and thus Stratasys seems to be focusing on ways to produce actual end-use parts in specific industries.

Shift away from machines: Perhaps this is a bit more subtle, but it also seems to me that Stratasys’ close work with industry has resulted in machines that are less “3D printers” than “integrated making equipment” that fits directly into manufacturing production streams.

For example, the costs of the new equipment wasn’t specified although it was quite clear they’d be far more expensive than current Stratasys gear. One reason for this is that the equipment is likely to be customized for each client. So it’s a “thing” that gets bolted into your production line, rather than a discrete “3D printer”. This is quite a philosophical switch for the company. I am not aware of any other company that has taken steps this deep into industry.

Competition: With their announcement, Stratasys has placed themselves on a part to depart from the “normal” markets of 3D printer manufacturers and get deep into manufacturing. While much has been said about HP’s entry into the 3D printer market and alternative vendors such as Carbon, neither of those companies has manufacturing industry development relationships as Stratasys has. To catch up would take many years, as it appears Stratasys has been doing in secret.

Timing: It is very curious that Stratasys – or any company – would announce a “concept” rather than a finished product. Speculation among the media included the notion that Stratasys wanted to poke at their new competitors to establish their dominance in the eyes of the market.

However, there’s likely a simple reason for the announcement: the gigantic manufacturing conference, IMTS, takes place in a few weeks. This conference is so large it occurs only once every two years. Thus, if Stratasys did not get the concept out now, they might have had to wait two years to get the same industry buzz. By then others might begin doing the same things, so I suspect Stratasys wanted to get the jump on them.

I’m very curious to see how the other major 3D printer manufacturers react to this, and it might take them a long time to do so.