It’s always amazing to see others leverage 3D printing in unexpected ways. One company doing so is Rocket Crafters.

Rocket Crafters is one of several space technology startups attempting to develop more effective means of putting objects into orbit and beyond. While they are certainly a lot smaller and less well known than say, SpaceX, Virgin Galactic or Blue Origin, they are nonetheless developing some interesting technology.

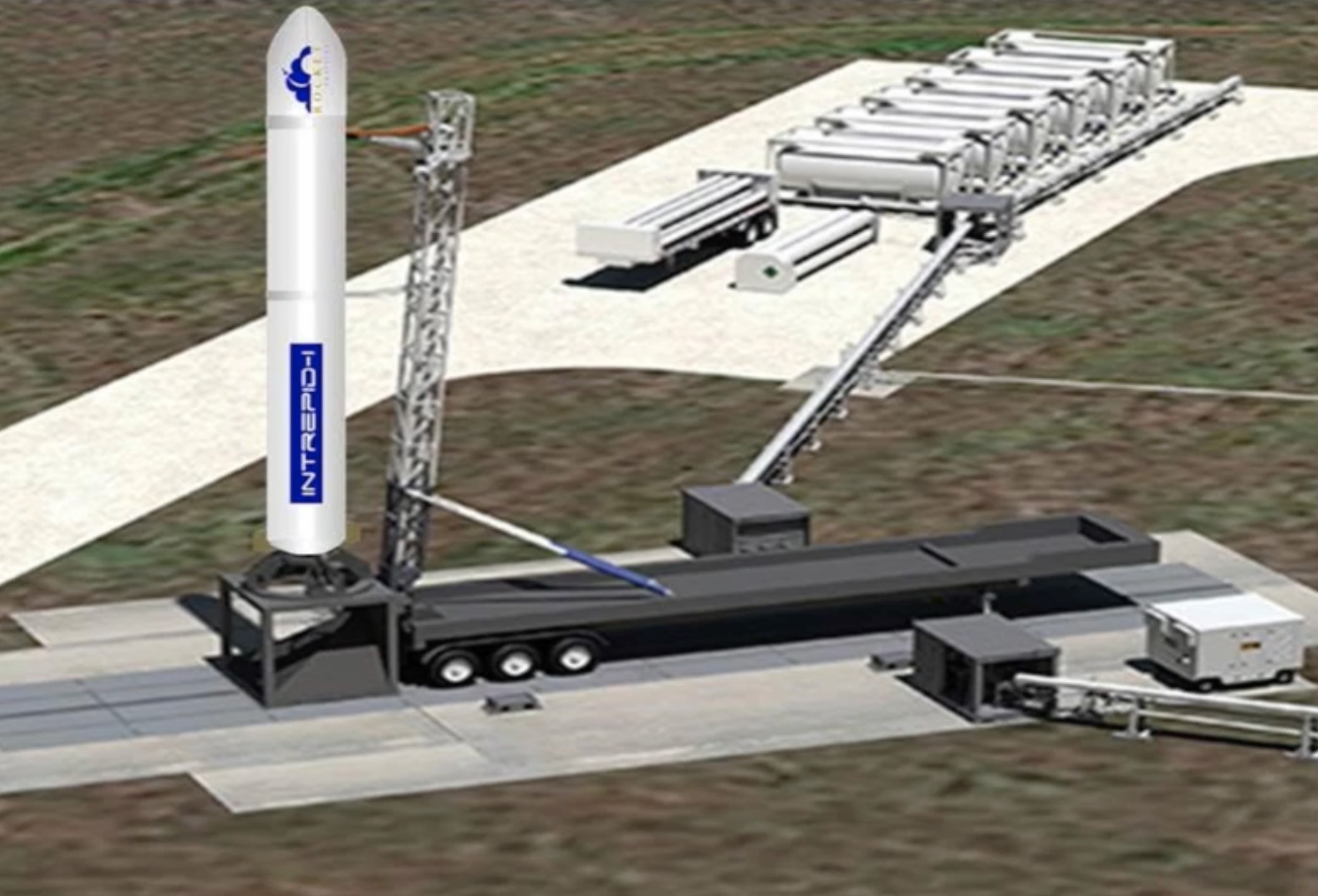

Their goal is to develop a launch system, the “Intrepid” that will be able to place small payloads (under 500kg) to custom orbits, including sun synchronous orbits well beyond the Earth. They say their goal is a system that would cost only USD$5.4M per launch, quite a bit less than even SpaceX.

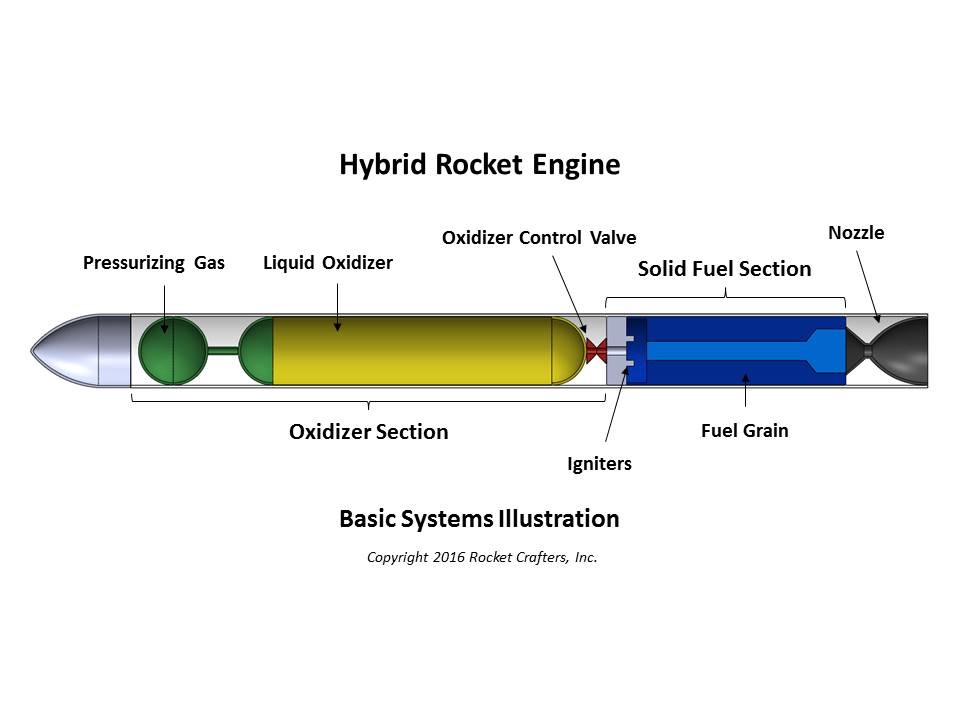

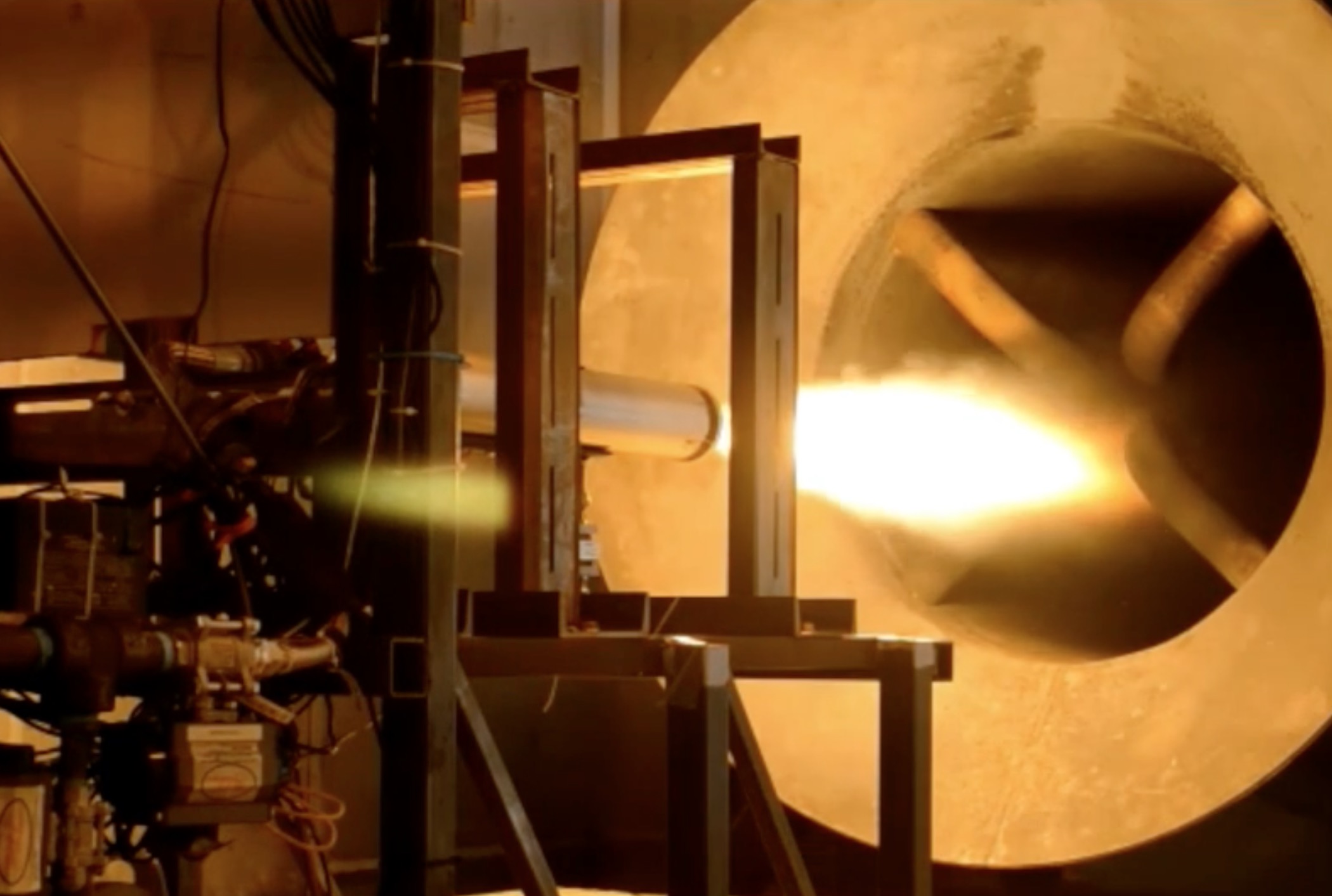

One contributing factor to their plan is the use of 3D printing technology, and specifically in their solid-fuel booster. In a solid-fuel booster, the burnable material is cast into a long combustion chamber, where it burns to produce thrust.

The challenge with solid fuel is that once you light it, it isn’t going to stop burning until it runs out of fuel. Normal solid fuel boosters have a uniform layer of fuel pasted against the sides of the chamber, and the burning occurs from the center outward in an even manner. This provides uniform thrust throughout the flight.

However, this is a problem: optimal flight patterns require the ability to jog the thrust higher and lower as various layers of atmosphere are penetrated. Since normal solid-fuel boosters are constant thrust, the flight profile has to go with the “lowest common denominator”.

But Rocket Crafters’ ingenious idea is this: 3D print the solid fuel in a burnable pattern that matches the optimum flight profile! In this way they can “throttle down” through the denser portions of the atmosphere where other solid fuel boosters cannot.

I can imagine they could design custom burn patterns for various flight profiles, each providing the most cost effective approach. It should enable them to make more effective use of solid fuel technology, which is far simpler to build than liquid fuels used by other rocket systems.

3D printing finds yet another productive application!

Via Florida Today and Rocket Crafters