We spoke with Tiertime’s Jason Wu, product manager of the new Cetus desktop 3D printer to find out more about this inexpensive device.

Fabbaloo: The Cetus 3D Printer is priced at an amazingly low USD$199 for the “super early bird” Kickstarter pricing. How is this possible? What manufacturing magic was able to achieve this low price level?

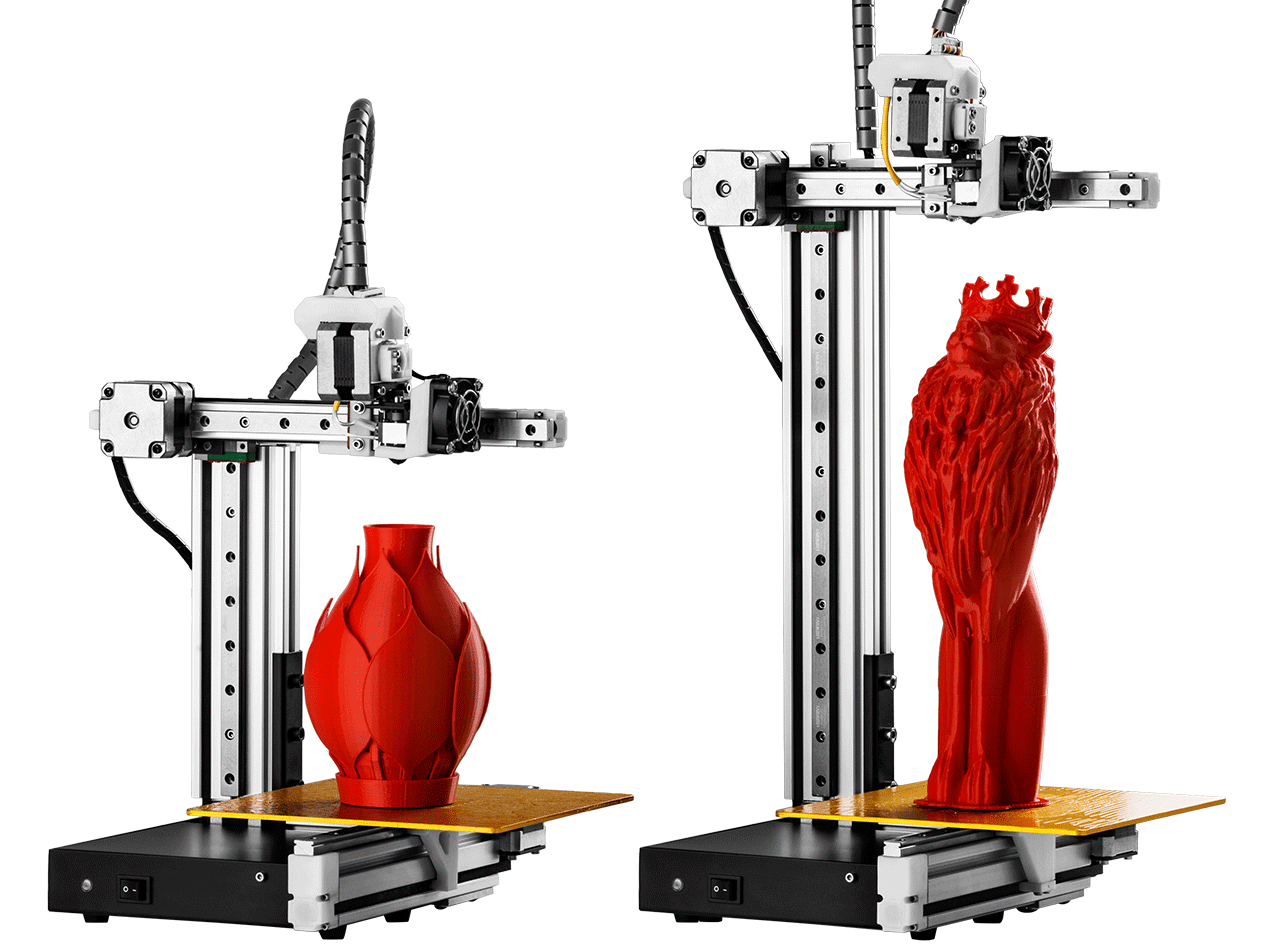

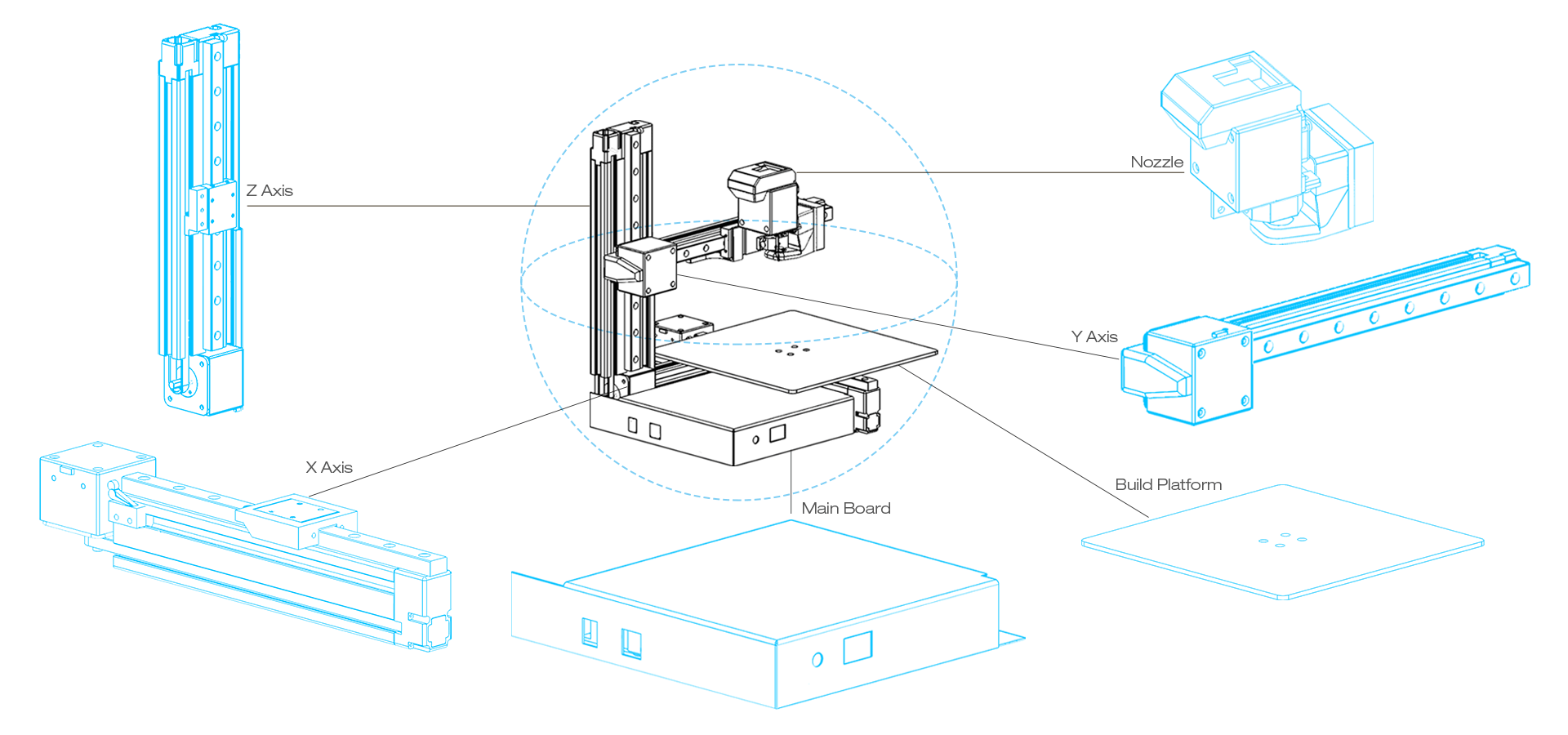

Jason Wu: The machine is made with aluminum extrusion, sheet metal, and some relative simple CNC parts. The plastic parts are 3D printed, e.g. the fan duct. So there is no upfront tooling cost for this product. The whole machine is also highly modular, X,Y, Z axis modules are almost identical. The minimalist design and simplicity also allow easier and faster manufacturing of the products. Therefore we can make the price more affordable with a relatively short lead time.

Fabbaloo: For such an inexpensive 3D printer, there are some interesting capabilities, like the ability to print layers as small as 0.05mm and a fairly large build volume of 180 x 180 x 180mm. What market are you targeting this machine for with these features?

Jason Wu: We are positioning this machine as a prosumer 3D printer with an entry-level price. Cetus is almost a plug and play device, first-time 3D printer users just need to fasten a few screws before it is ready to print. The machine is calibrated in factory so there is no need for the user to do so. We provide straightforward software with optimized printing parameters so a beginner does not need to know all the printing parameters before getting started.

For advanced users, Cetus also provides freedom for tinkering. The software can change print temperature, so users could experiment with different materials. We will support GCODE in the near future, so the Cetus could be used with other slicers on the market.

The printer’s extrusion body is able to accept standard T-nuts so user could easily modify it. An extra 5V output is on the extruder head, so an electronic add-on is also possible.

We are also providing upgrades: In the kickstarter campaign, backers could choose to upgrade to a taller version with a build volume of 180x300x180mm. A series of upgrades are also planned and will be release in the future.

In one sentence, Cetus is targeting the general desktop 3D printing market covering from beginner to enthusiast.

Fabbaloo: The machine design seems to be very lightweight due to fewer parts. How does the machine maintain printing accuracy with far fewer rods and gantries used in other, more expensive machines?

Jason Wu: The printer use high quality linear rails on all 3 axes; our baseline is to use HIWIN or better rails. The body is full metal and therefore very rigid. This results in excellent print accuracy and makes the printer very quiet as well.

Fabbaloo: I’ve not seen an inexpensive machine with the ability to change nozzle sizes (the Cetus 3D offers 0.2, 0.4 and 0.6mm nozzles). What are these able to do for the operator? What benefits do they offer?

Jason Wu: The different nozzles will provide much more freedom for operators to get better results for different purposes. If you need highly detailed prints, the 0.2mm nozzle could give double the resolution of the 0.4mm nozzle. You can go to our Kickstarter campaign to see the print samples. On the other hand, if you need something to be printed faster especially bigger prints, the 0.6mm nozzle will come in handy. The 0.6mm nozzle is also excellent for printing flexible materials such TPU/TPE and composite materials such as wood composite or metal composite materials.

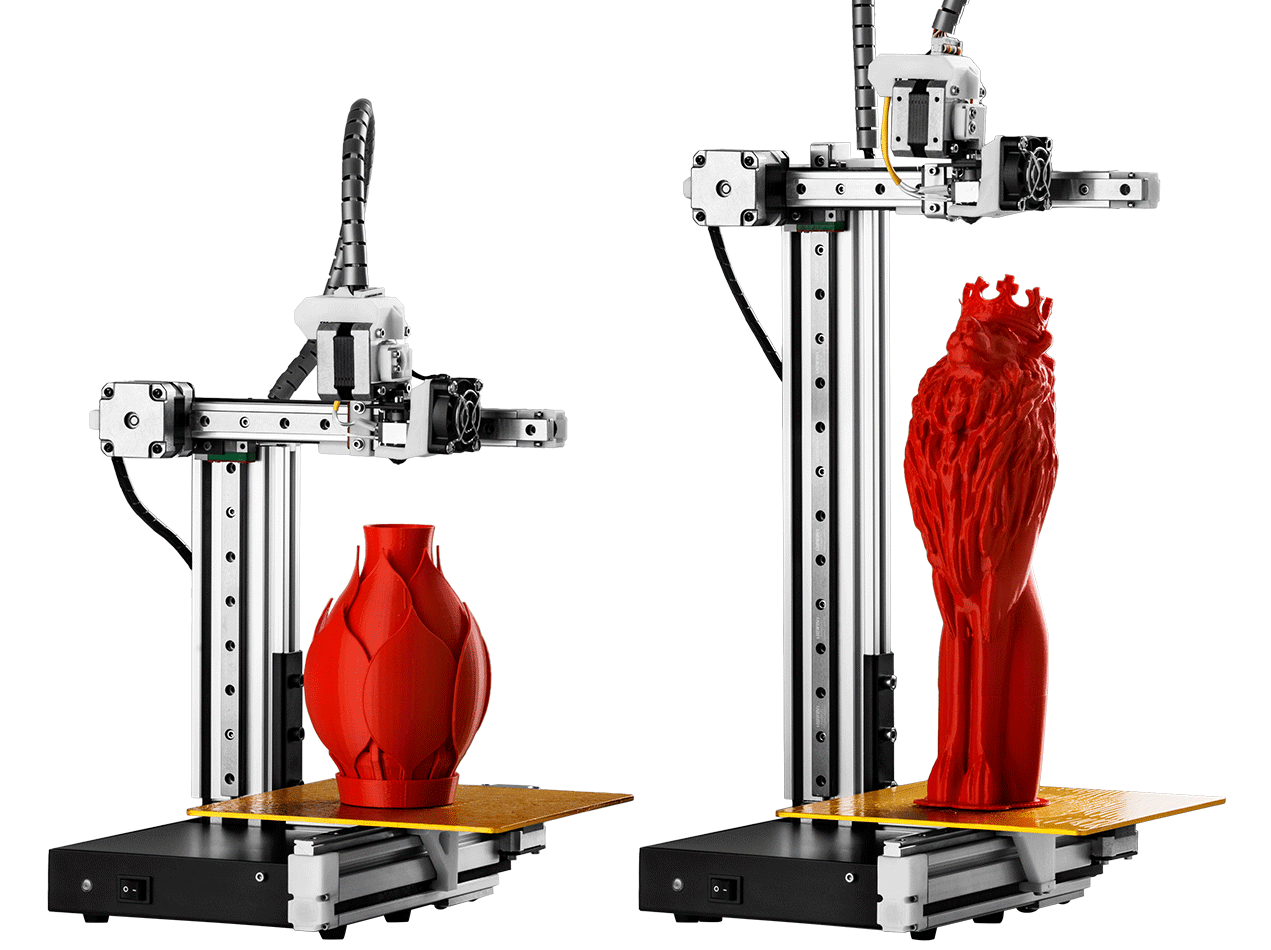

Fabbaloo: I’m told there are two versions of the Cetus 3D, one being the extended version. What is the difference and why are two versions offered?

Jason Wu: The only difference between the two is that the extended version has a longer z-axis, it provides 180x300x180mm volume which is 66% more than the standard version.

Thanks to the open design of the printer, all 3 axes could be extended. We think that some people may want to have bigger print volumes, and the easiest axis to extend is the Z-axis, therefore we made a taller version. We may also provide x-axis extension upgrade in the future.

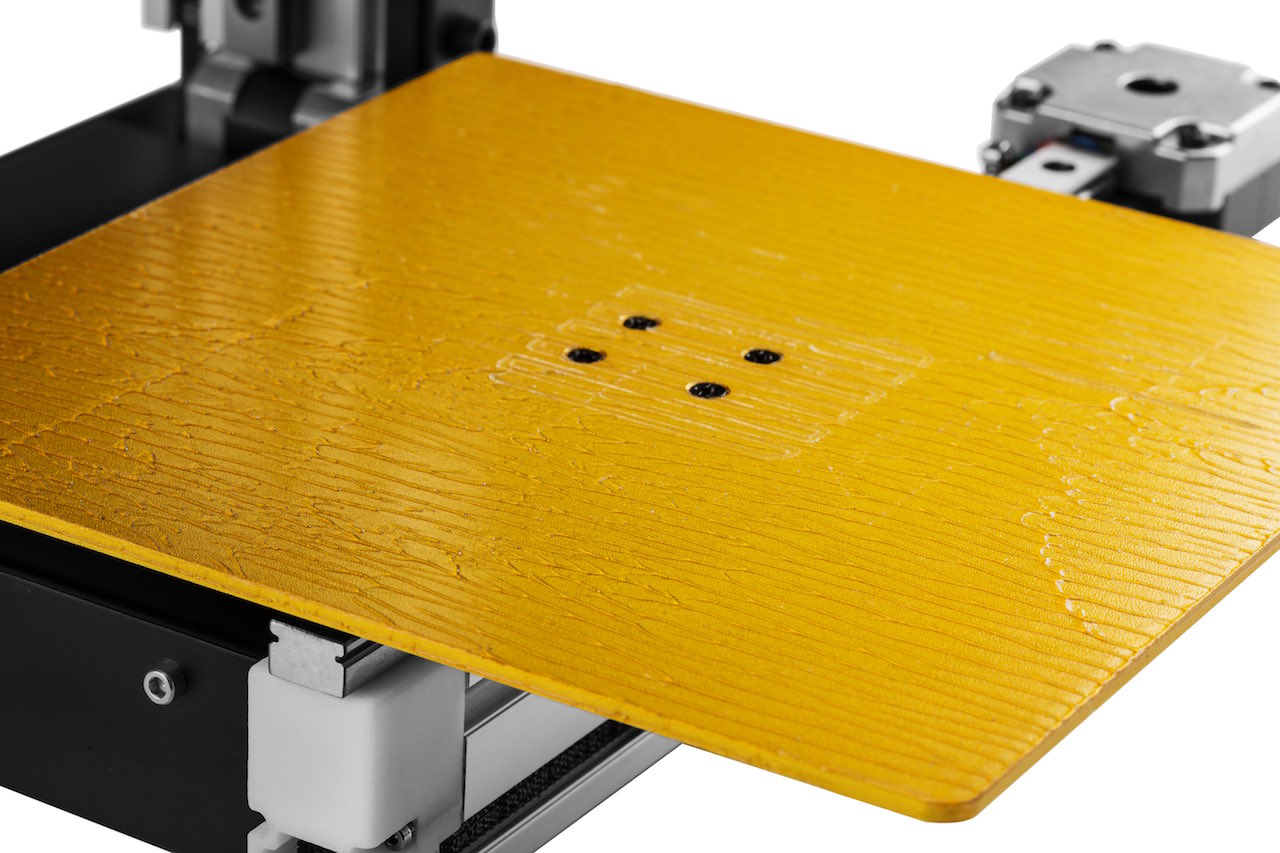

Fabbaloo: The Cetus 3D printer does not include a heated print surface, so how do prints adhere to the print bed during operations? What method of adhesion is used? What materials are possible to print?

Jason Wu: We put a special coating on the build plate, it is sticky to PLA but gives a sharp separation if a little force is applied to pry the printed object. We found this coating works very well with PLA and some other materials such as TPU and PETG.

The current configuration of Cetus does not provide a heat bed, so some materials will not work, such as ABS. We will provide future upgrades for more material support.

Fabbaloo: What print and travel speeds are achievable on the Cetus 3D printer?

Jason Wu: The perceived normal printing speed is about 50mm/s, and travel speed is about 100mm/s.

Fabbaloo: How has the machine been received by the public so far?

Jason Wu: We reached the goal of 100,000 on Kickstarter already. A lot of people are quite excited about the printer. We are sending a prototype printer to external testers for evaluation, and so far most of them give very positive feedbacks about the printer.

Fabbaloo: I’m sure many people would like to get their hands on a Cetus 3D printer. When do you expect to deliver machines?

Jason Wu: The Kickstarter campaign is already online, and it will end on 9th Oct. The Super Early Birds are all gone, and Early Birds are running low, so don’t miss the chance to support Cetus. We are working hard to make sure the first 1,000 backers will get their Cetus printer by Christmas!

Via Kickstarter, Cetus3D and Facebook