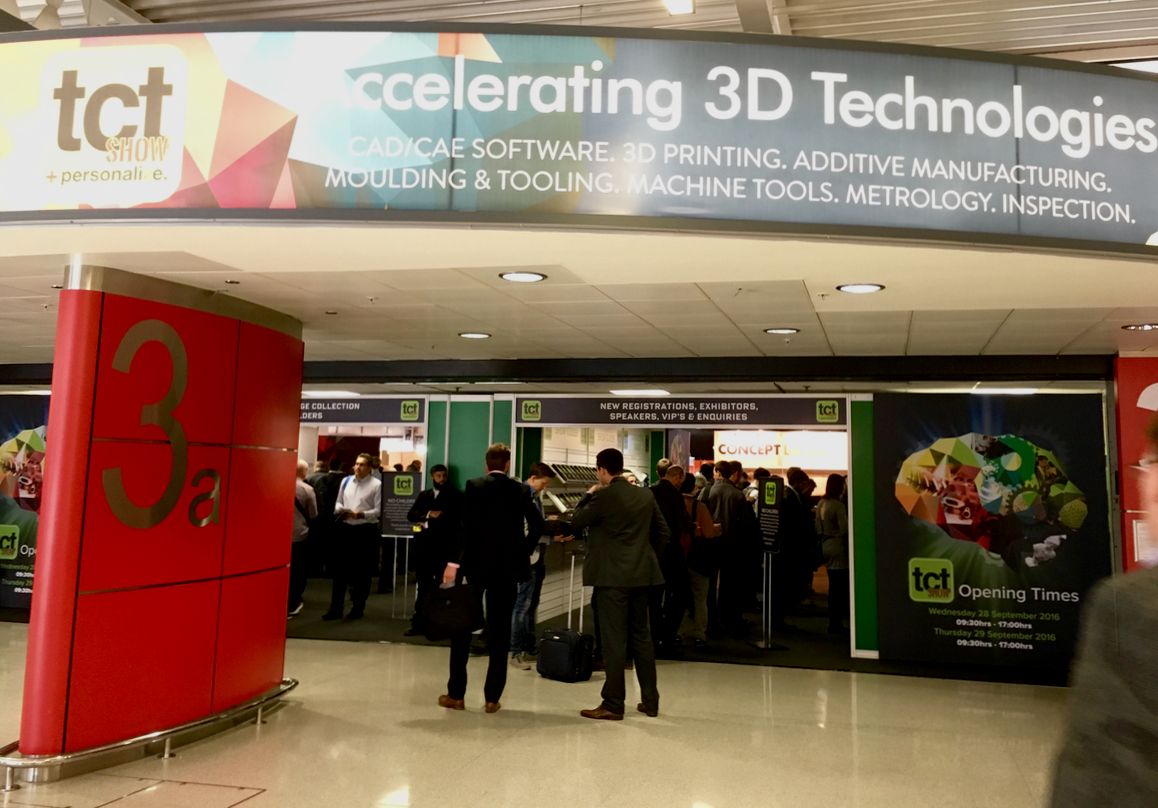

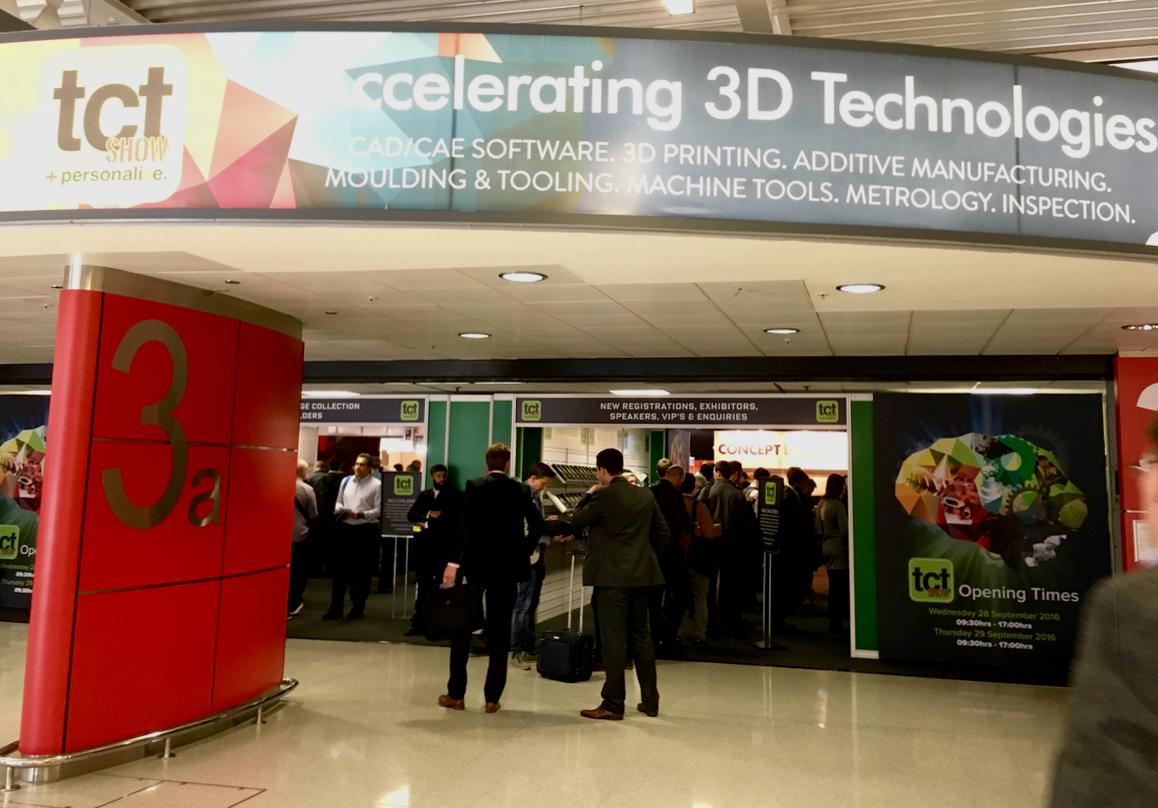

The TCT Show, this year boasting its 21st edition, continues to go from strength to strength.

Back at the NEC in Birmingham in the heart of the UK’s still strong manufacturing belt, the show not only brought together a wealth of additive manufacturing and product development exhibitors, it also manifested a real and vibrant buzz of positivity around the 3D printing industry. While it can be argued that TCT is a regional show, albeit the very strongest in the UK, I believe it reflects an increasingly positive (again) global trend in additive manufacturing and 3D printing, in much the same way as the Rapid (USA) and formnext (Germany) events do in their respective regions.

Each of these shows do draw global exhibitors, but the visitor numbers for each reflect a high regional bias, and I think this is a contributory factor to the increased number of shows across the year. I’m sure there are plenty of people that would argue differently, but that’s my take.

Back to TCT though and a surprisingly fast trip down the M6 saw me heading into the NEC slightly ahead of schedule and with time to grab a much needed coffee, and I was barely through the front door when I bumped into the Carbon team. Exhibiting for the first time at TCT, they were excited to say the least and it was a lovely start to the day. I was able to sit down with Phil DeSimone and Paul DiLaura, Carbon’s new VP of Sales who came to them from Dassault, later in the day to probe more specifically into Carbon’s novel business model, expansion intent and continued material development.

Carbon’s stand on the show floor was incessantly busy over the two days, but there was considerable disappointment from various quarters at the lack of a working machine at the show. However, the first platform will not arrive in the UK until Q1 next year.

Another company that had a massive presence at TCT was HP. The company was, quite simply, making a statement to the AM community relative to the size of its stand. But they did suffer from a similar problem to Carbon, in that there was no working machine at the show. Shipping of the MJF platforms are quoted as Q2 next year. May I was told. But the positivity that both Carbon and HP are generating was palpable and a contributing factor in lifting the entire sector, I think.

My foot was barely over the threshold of Hall 3A, before I ran into a couple of old favourites within a few minutes of each other. Catching up with Andrew Allshorn of @3DSquared and Neil Burns of Croft AM basically set the tone for the day, with reports of fast growth and exciting new projects that I am not allowed to report on yet, but some of the clients’ names they were whispering were really very impressive, and indicative of the attention and application of additive tech today. The secrecy and NDA frustration remains the same, though, unfortunately. Drives me mad!

I was delighted to be able to sit down with Prof Phil Dickens and his wife Carrie. Phil was speaking at the TCT conference, which unfortunately passed me by this year, but was also representing Added Scientific. My eye was caught by Carrie’s jewellery designs, however.

A talented designer, she had some of her additive pieces with her – as demonstrators. They are beautiful, but we were chatting about the process of manufacturing them both the challenges and the results. The challenges it turns out, come with the post processing and tolerances — echoing the voices of many manufacturers regardless of sector.

I was also fascinated to learn about some of the other projects being undertaken by consultancy firm Added Scientific. Of particular note was the Functional Lattice Package (FLatt Pack) software, specifically being developed to create strong lattice structures that can be additively manufactured that enable a wide range of applications to benefit from light-weighting, which brings huge cost savings for users of AM.

This was a recurring theme from vendors and users alike over the two days and a primary driver in the adoption of AM technologies — right up there with time savings. No matter what else changes across the additive landscape – these themes remain constant.

A good example came from Stratasys’ show announcement of its partnership with French company Schneider Electric, a global organisation that has adopted both Fortus and PolyJet processes across its operations and has gone on the record to report 90% time and cost savings as a result.

Over the two days at TCT, virtually every conversation I had with vendors and visitors alike was peppered with this sort of positivity. However, I say ‘virtually’ because there is still much work to be done, as evidenced by a conversation I had with independent consultant Kevin Smith — work that needs to be done outside the affirmative community hubs that events like TCT create.

Many of the vendors were reporting that the awareness and understanding of visitors was noticeably higher than even last year. But while attendance was high, what about all those companies that have not engaged with AM, and those that have but still don’t “get” it. As Kevin and I talked about the disruptive nature of additive tech he told me how it is still being resisted by a large number of companies — mostly companies that are so entrenched in traditional ways of working – such as foundries – that they can neither comprehend or believe the advantages that are presented to them. Even when the costs, based on real benchmark products, are set down right in front of their eyes.

One project that Kevin cited was for a company where he could demonstrably prove vast savings in part cost, improved part quality and hundreds of thousands of pounds saved in shipping costs. The company refused to proceed based on a complaint of “but there’s no tooling!”

“Unless we change this perception, the disruption just won’t happen in production,” Kevin told me. He’s a man on a mission — a mission we all need to undertake!

A couple of companies were noticeable by their absence from TCT, mostly US companies such as 3D Systems (who were represented by resellers), ExOne, Optomec and Sciaky. But also Prodways and SLM Solutions, although the latter was present via its UK distributor Laser Lines who had a very impressive stand in the centre of the floor.

In contrast to the absentees and a couple of the big players present, Picsima was present on the show floor with a working machine, 3D printing in silicone. Unsurprisingly, they were getting a great deal of interest. Even while the team behind this process has not acquired the funding for full commercialisation — yet — I suspect it won’t be long. The potential of this process is phenomenal.

Concept Laser’s stand at TCT was continually inundated with visitors, it was hard to snatch a few minutes with Ray Neal to catch up, but I finally managed it on day 2 of the show. The big story there was the production of a medical device component, highlighted in a keynote presentation by Alex Berry of Sutrue, which demonstrates just how disruptive AM production can be. Full story to follow, a story that could well set a new precedent!

I also managed to catch up with the Arcam team, and was delighted to find the company’s new Marketing Communications Manager was Leslie Frost, previously of Stratasys. To say that they were all upbeat about the GE bid for acquisition would be an understatement! I did push on how, if the deal is completed at the end of October, it would affect Arcam customers, particularly those operating in the aerospace sector. The resounding response was that it would be better, and that yes, GE will absolutely supply and service competitor companies. It happens already with other products and services across the aero sector. I have to say, I still have a cynical voice in my head on this one, but I guess we’ll only find out for sure when — indeed if — the deal goes ahead.

Across day 2 I was able to sit down with a number of different company leaders. Interviews with Mcor’s CEO, Conor Maccormack; Zinter’s CEO, Shane Nelson; CEL Robox’ MD Chris Elsworthy; and MakerBot’s European MD Andy Langfeld were all open and insightful affairs that will result in upcoming posts.

Similarly, on the spot landings on the stands of FormLabs and Envisiontec produced equally illuminating information. I also got to see the new stereolithography (SL) machine developed and manufactured in the UK by RPS. From the specs it looks impressive, and it has an open materials approach that I think will serve it well. I spoke with Rory Jackson about it in some detail and what the guys at RPS don’t know about SL is not worth knowing. This is one to watch I think.

One thing that really struck me at TCT this year was that there were still a fair proportion of desktop 3D printers on show, and without exception, of the ones I caught up with, they are all reporting huge growth and full order books. Some are even struggling to meet demand, it’s that high. Again, without exception, they believe that this is because the nonsense has died down and the emphasis is now correctly balanced and targeted at the education, design and concept development markets. The stands of BCN, Hawk3D Proto, Zortrax, Prusa, Create3D, E3D, CEL Robox to name a few were constantly busy with scores of visitors.

There was so much to see, so many people to speak to, it was only as I was on my way home, when the M6 was much less kind that I realised just how many people I had missed. To be honest, I doubt I could have spread myself much thinner, no matter how much I wished it. There may be a resolution to this for 2017, the organisers of TCT wisely announced that next year’s show will be three days, and that will continue from now on.

Good move.