I’m watching a video demonstrating a “meta material mechanism” and the mind boggles at what become of this concept.

The demonstration was developed by researchers at the Hasso-Plattner Institute in Potsdam, Germany and involves creating mechanical devices not with independent parts, but with a single object made from meta-materials.

Just watch this video to get the gist of the concept:

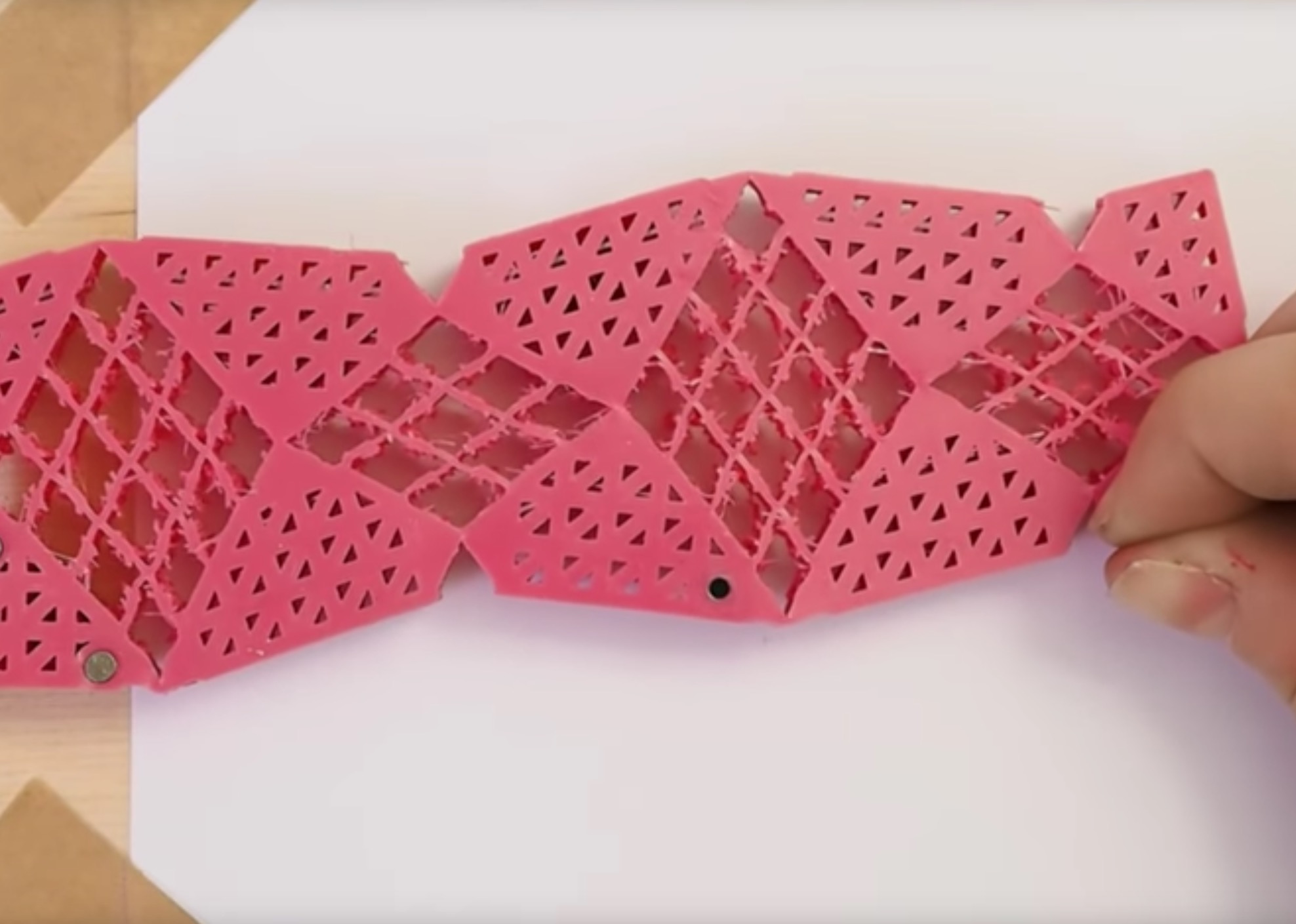

In this example, it seems they’ve created a specific meta-material – a structure with flexible and rigid elements that enables motion. The motion performs a designed task, to open the door latch.

And that’s not all. The research team has developed several mechanical objects using such designed materials.

Such complex structures are easily 3D printed on many inexpensive machines, so you might suspect this could become a common practice. However, the secret to this approach is not the printing, which merely enables the process to occur.

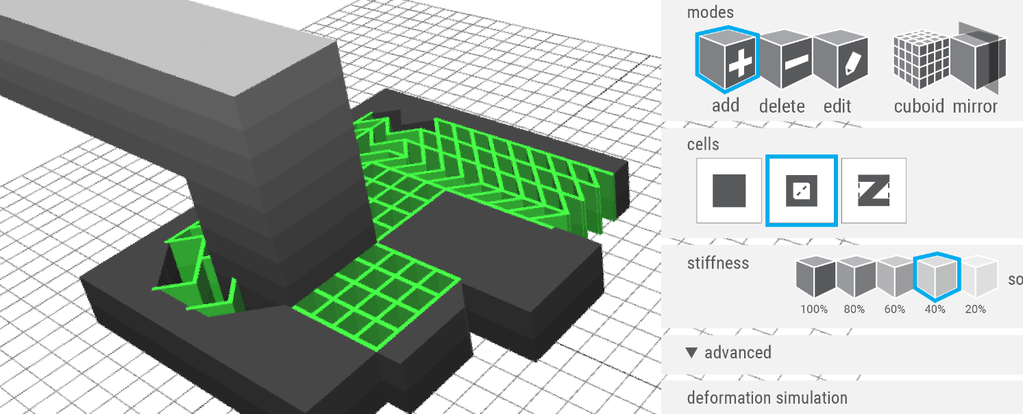

The true heart of this approach is the software used to design the objects. Such software would have to understand the desired motions and somehow generate the appropriate meta-materials for the job. In other words, the interior structure must match the required motion.

But it appears they’re well on their way to creating such software, which I suspect would eventually end up with a set of mechanical “elements” that could be combined into more complex mechanisms.

From the look of the prints, it also appears they’re using a single plastic to produce these objects, and leveraging the principle of “thinner is flexible”. Thicker portions comprise the “solid” sections of the print.

The implication here is that anyone with the necessary software and a 3D printer with a slightly flexible plastic could theoretically produce such amazing objects.

But, as with any 3D modeling, you’ll need a very good imagination.

Via HPI