There have been many aborted attempts at producing recycled 3D printer filament, but Reflow’s approach appears to be successful.

In the past I’ve seen many attempts at producing desktop machines that recycle plastic into 3D printer filament. Typically the concept is to collect leftover prints or plastic, grind it up into fragments and remelt them into filament, but by and large, these ventures have been entirely unsuccessful for a variety of important reasons:

- The quality of the input plastic is questionable, unpredictable, contaminated, multicolored and inconsistent

- The input material can be different types of plastic that cannot be mixed into a proper filament

- Output filament quality had no means for quality assurance (measurement of filament diameter and roundness)

- Insufficient (or no) recognition of the requirement to properly cool the extruded filament in a controlled manner

- Lack of a means to collect the output filament on a proper spool

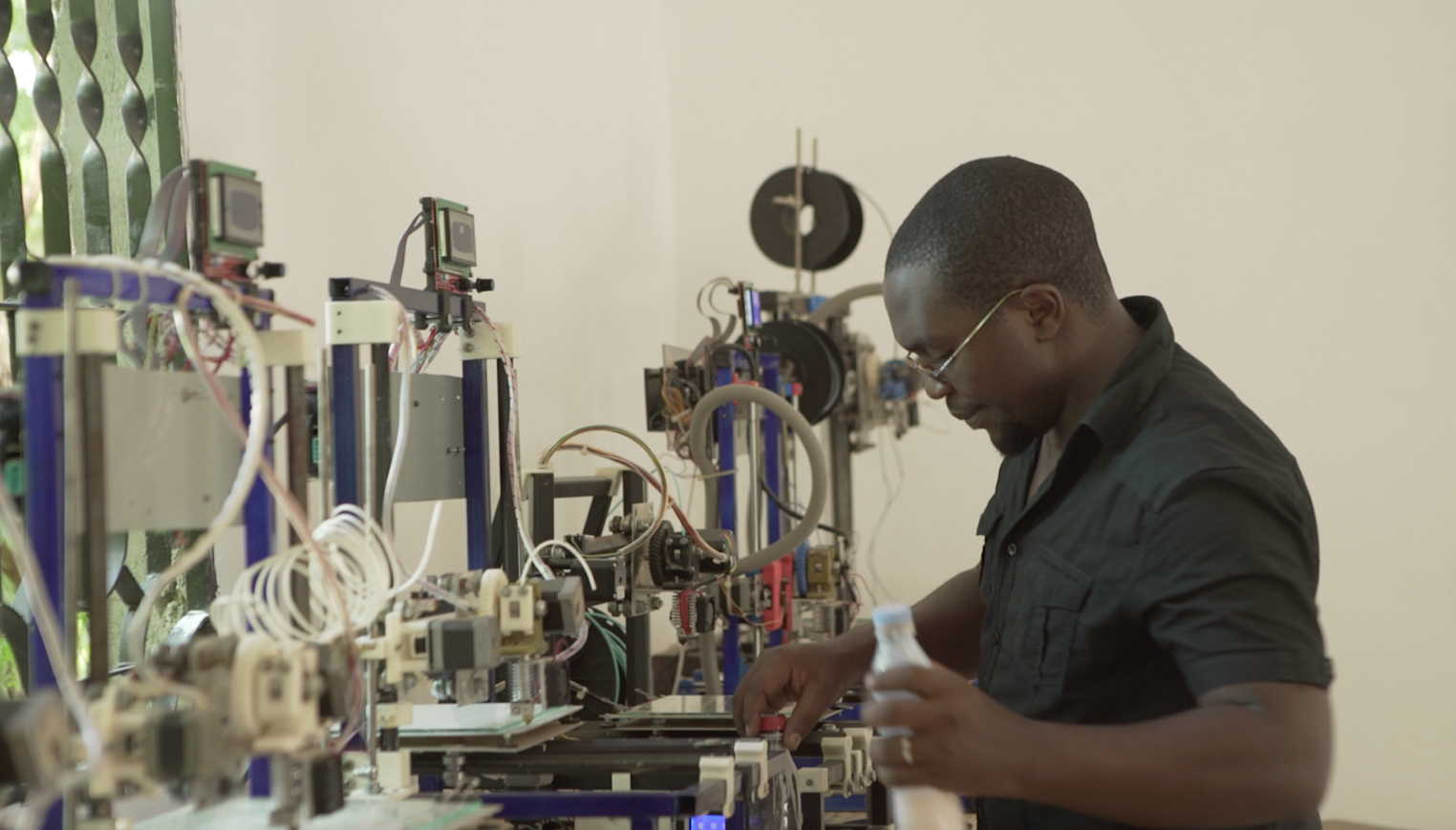

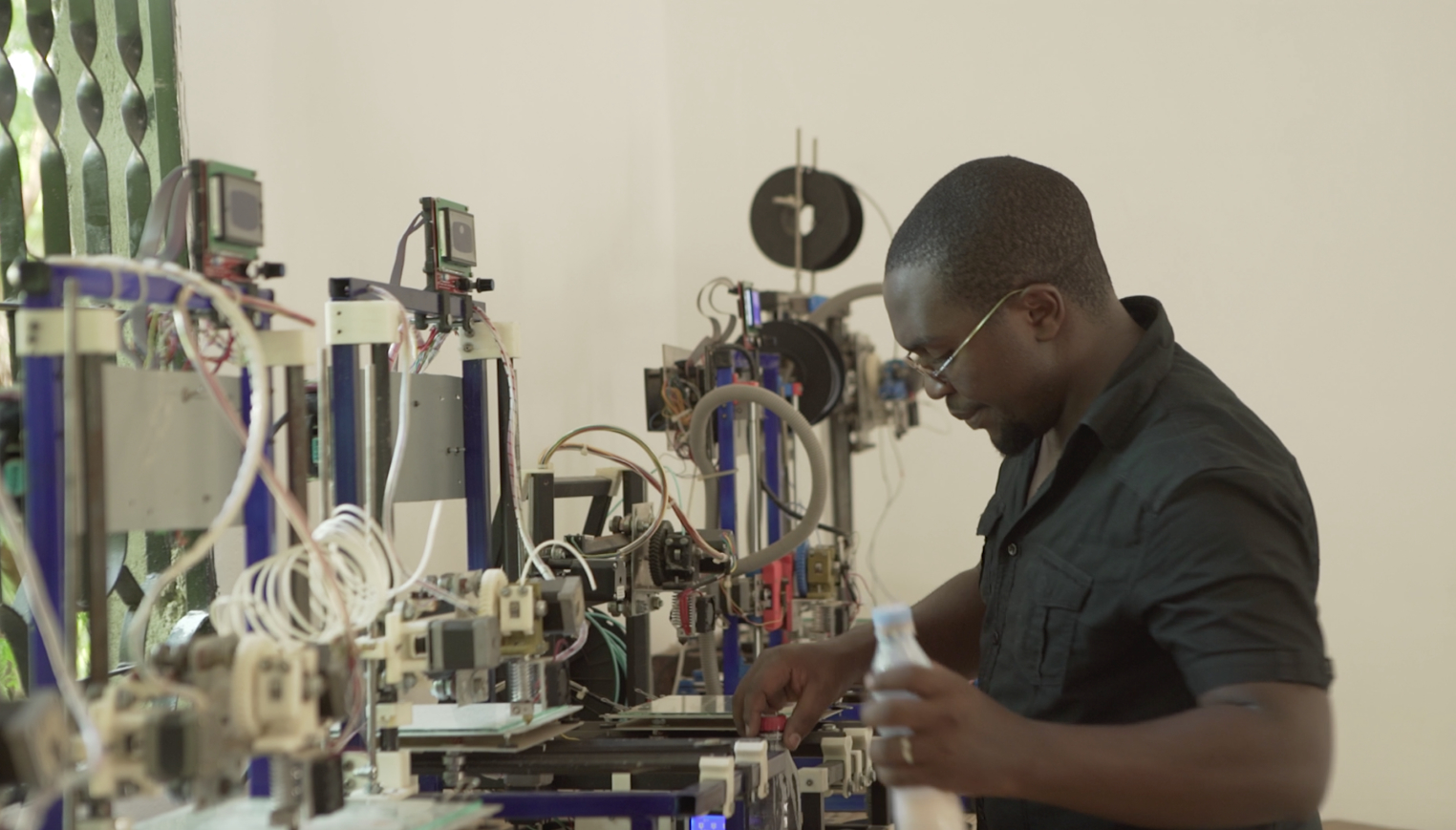

When I first spoke with Reflow’s CEO Jasper Middendorp, I expected yet another questionable recycling venture. However, I was very pleasantly surprised to find out this company has actually not only considered all these common issues, but have implemented solutions for them, too! Let’s see what they are doing.

Their goal is to provide a means for developing countries to locally produce usable 3D printer filament, and their initial locations are in India and Dar es Salaam, Tanzania. They’re looking for sites having good existing waste collection systems on which they can piggyback the collection of appropriate plastic materials. Ultimately they want to establish an international network of recycling centers producing zero-waste 3D printer filament.

The side effect of this, of course, is to encourage the development in such countries by empowering their engineers with inexpensive making materials. You can’t expect those in poorer countries to be able to purchase typical spools of filament at developed country prices, particularly with arduous import duties imposed on top of those prices.

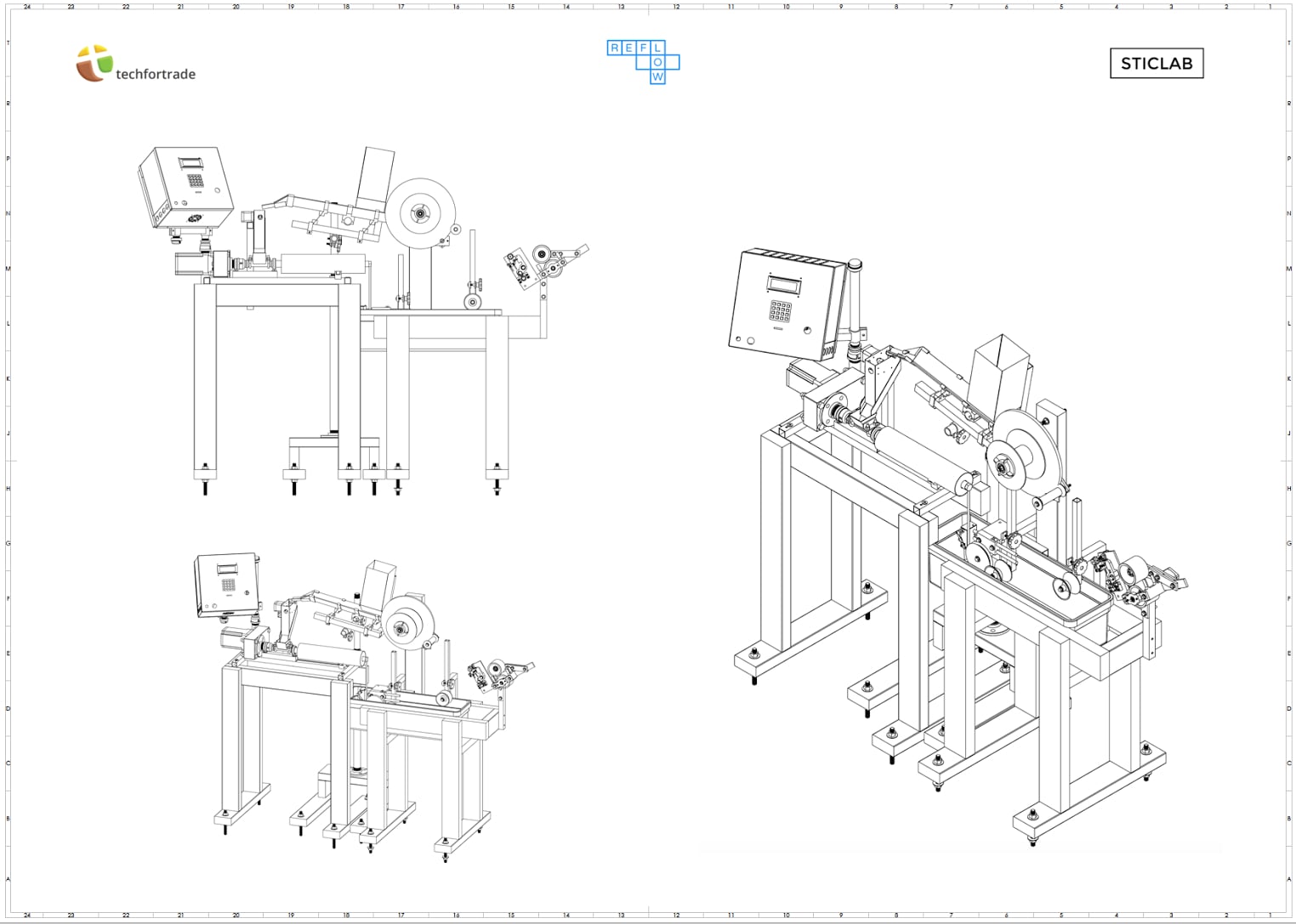

And so Reflow designed an open source mechanism to produce filament. What attracted my attention was that their design includes a number of critical features that should enable successful filament production:

- Restricted selection of input material (e.g. specific plastic bottle types only)

- A defined cleaning process using chemicals, water and tumbling

- A controlled-temperature water bath to accept hot extruded filament

- A laser system, placed at the extruding nozzle, which constantly measures output filament diameter

- Realtime feedback to the motor system to adjust flow

- A “starve feeder system” and single screw to drive material forward

- Use of three independent heat zones through the process

Such equipment can be locally built, they say, for only USD$1,500 and will enable the production of approximately 10kg of usable 3D printer filament per day. That could enable a very reasonable business, at least in larger centers where there may exist good numbers of 3D printers requiring material. Dar es Salaam, for example, is a city of more than four million, which gives you a clue why they are starting there.

Reflow isn’t stopping there. In addition to the high-quality filament machine, they’re also developing a kind of ready made web shop that can be used by those wishing to startup a local filament business, complete with branding, training and more.

The machines are to be launched in October.

I believe this is a hugely valuable investment by Reflow, as it will enable 3D printing to feasibly exist in places where it would otherwise be far too expensive. Filament, after all, is a regional business due to shipping costs. But the regions producing today’s filament are almost never in third world countries, leaving the resident entrepreneurs facing high material costs.

Unless they can organize a Reflow recycling center.

Via Reflow