Optomec announced an improvement in their Aerosol Jet Technology that permits production of very small structures.

Optomec’s Aerosol Jet Technology is a bit different from typical printers. In their method, an aerosol of material is blown into the build space where it is instantly fused using a high power laser. They’re able to 3D metal in this way, for example.

They’ve also pioneered methods of 3D printing electrical circuits into 3D models, so their technology is quite versatile.

Now they’ve announced a new capability:

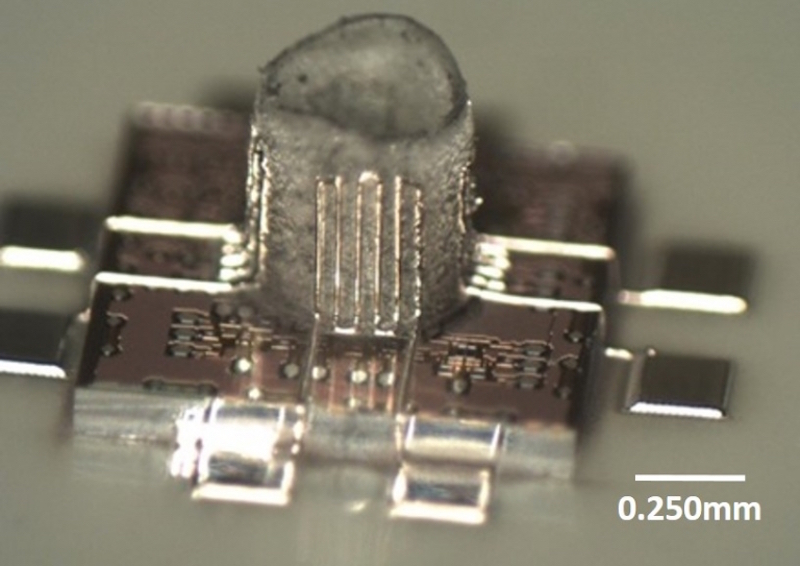

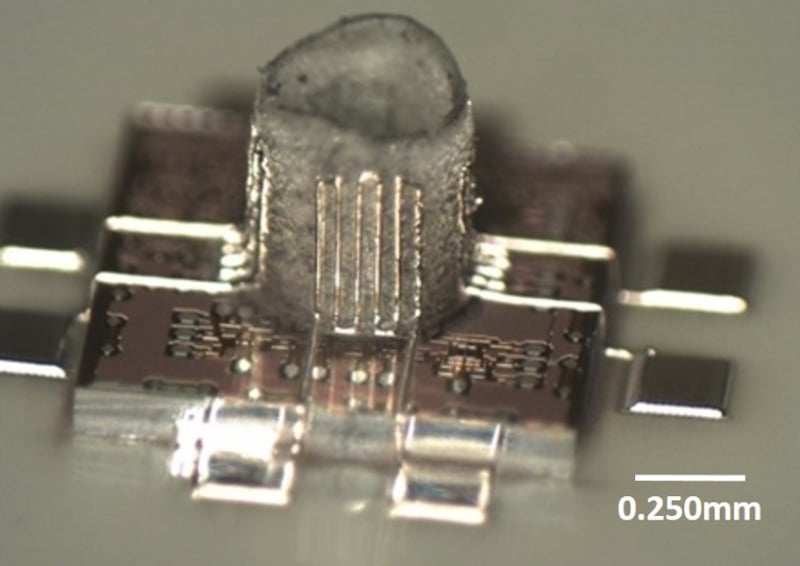

Aerosol Jet Technology can enable 3D polymer and composite structures to be printed at the micron scale with embedded electronics. This breakthrough has significant potential to reduce the cost and size of next-generation products used in the electronics and bio-medical industries.

How small, exactly? They say they can produce lateral structures as small as 0.01mm and vertical structures between 0.001 and 0.0001mm (that’s 1 micron to 100 nanometers!)

But how, exactly have they done this? They explain:

This new capability is enabled by combining Optomec’s proven Aerosol Jet solution for fine feature printing with a proprietary in-situ curing capability for rapid on-the-fly solidification.

The rapid solidification is the key to producing very fine structures.

Optomec says they can produce micron-level structures in photopolymers and “certain composite” materials. They’re also able to plant electrical traces on the surface of the print, as they had been able to do previously.

Via Optomec