A project by Netherlands-based Aad van der Geest has created “ColorPod”, a concept for converting a monocolor desktop 3D printer into a full color machine.

The process used by ColorPod is actually quite familiar: it’s the same process used by the now-defunct ZCorp (acquired by 3D Systems in 2011). It’s a powder-based process that combines color inkjets and binder to enable building full RGB-color objects.

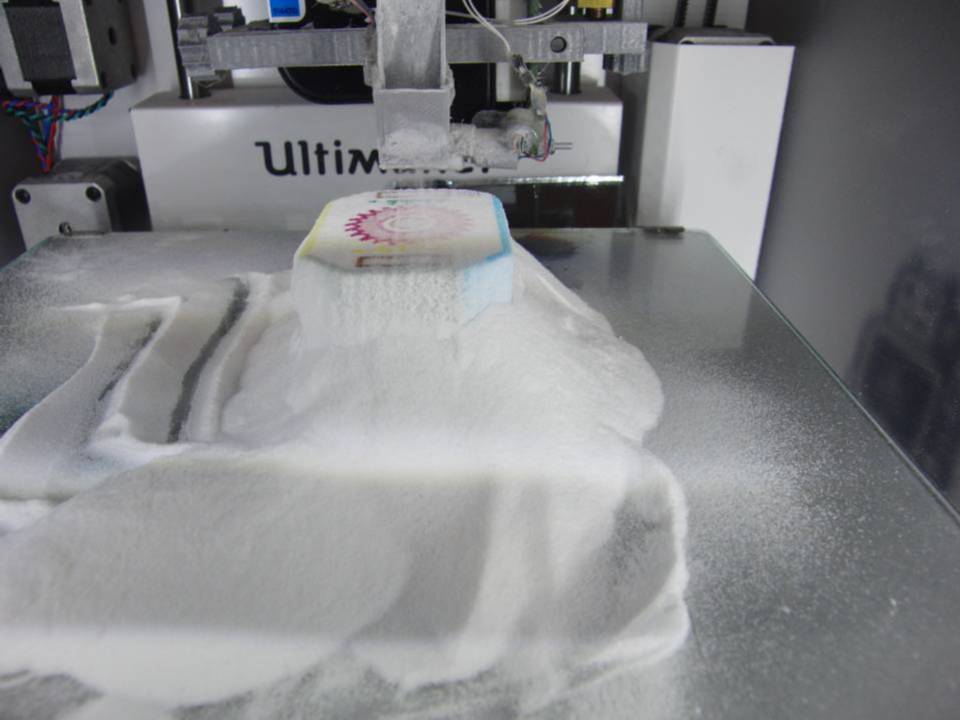

Here’s how it works:

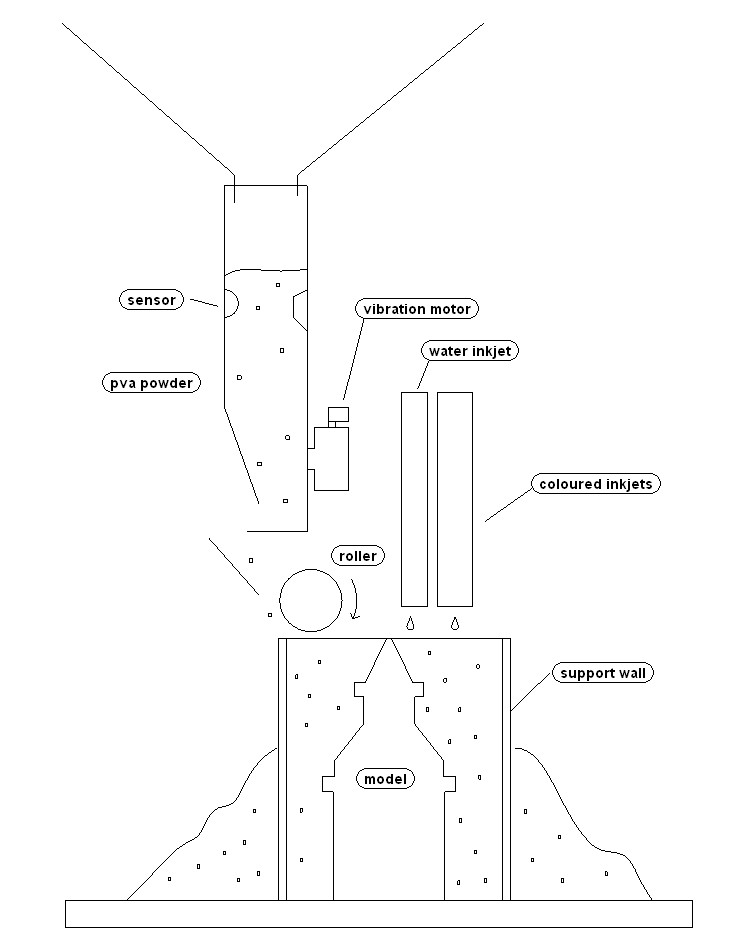

- The print head on a typical desktop 3D printer is replaced with a mechanism that can deposit powder and drive inkjets

- The “powder head” contains a supply of fine powder, which might be wallpaper paste, plaster, sugar or other substances one could experiment with

- The powder head uses a roller to deposit a smooth layer of powder

- The inkjet head then performs a second pass on the flat surface of the powder, selectively dropping colored ink onto the powder

- The print bed is slightly lowered and the process repeats

van der Geest also provides software to drive the ColorPod system, an essential component.

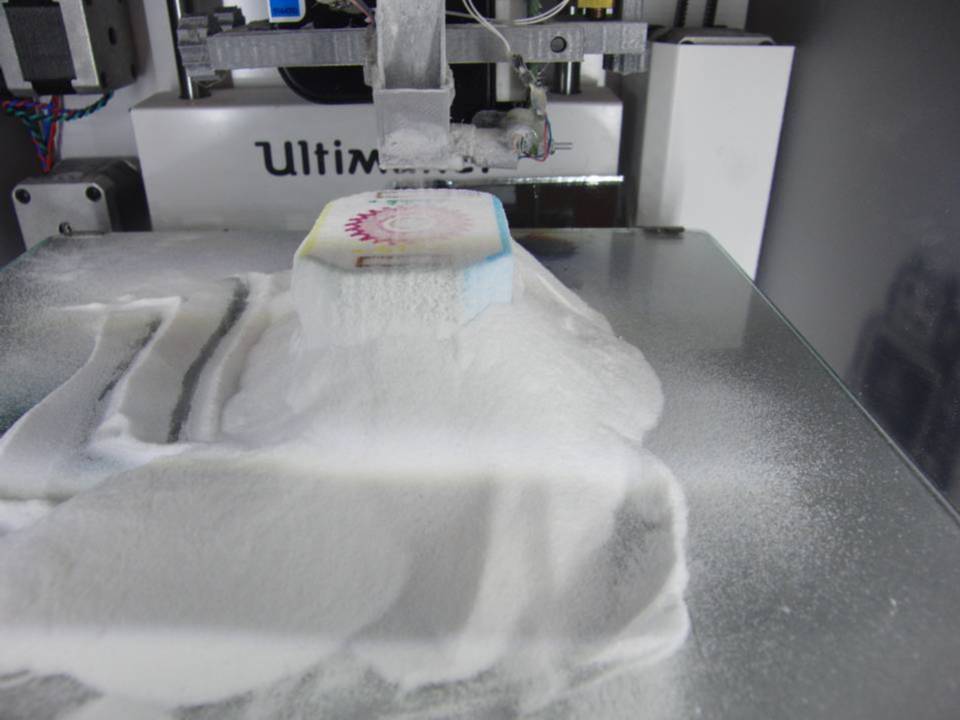

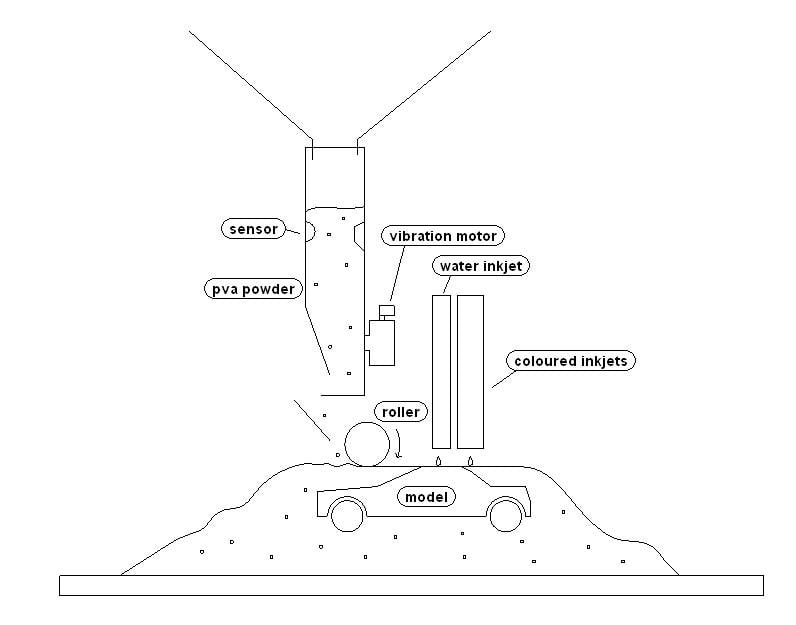

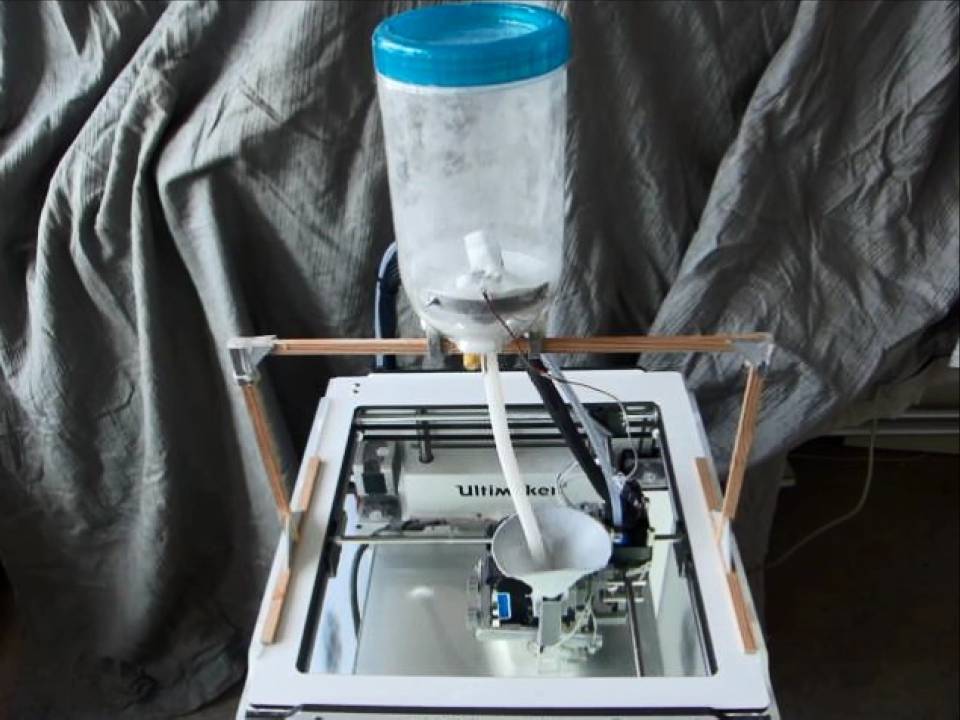

You can see a ColorPod prototype in action in this video, where it’s attached to an Ultimaker:

The print is definitely in color!

As you might imagine, unless you take special steps to design a method to corral the loose powder, your ColorPod-equipped desktop 3D printer will be covered in the stuff. While the design of a powder-control structure would vary by machine, I think this should be almost mandatory to keep powder out of the mechanical components.

One very interesting variation proposed by van der Geest is the use of “support walls”. These would be throw-away walls surrounding the print to permit deposition of powder for tall prints. You can imagine the powder would naturally form a pyramid shape as it collapses under its own weight. If a 3D model doesn’t fit into a pyramid shape, then you’d have to use the support wall technique.

After printing there is the matter of solidifying the print. Ink is certainly not a good binder. This is also a problem encountered with the ZCorp process, which is solved by infusing the porous print with a more robust binder, such as super glue (Cyanoacrylate). This process will not only harden the model, but could also bring out the colors, which otherwise will be muted by stray powder. However, some reports say that white portions become slightly transparent.

While you can actually 3D print color objects with this add-on, remember that they will be small and quite fragile, even when infused with super glue. The colors could be less than your expectations.

The ColorPod is designed to be installed on any RepRap-style 3D printer, which includes a great many designs and even some commercial products. This project is not for everyone, as you’ll require some technical skill to install and use ColorPod. That said, if you were able to build a RepRap 3D printer, you probably can handle a ColorPod.

Can you get one? Yes! van der Geest is selling them on Tindie at a cost of USD$349 for a fully assembled version that you can install on your RepRap 3D printer, or a set of parts for USD$139 where you can 3D print the remaining parts to build your own.