A few 3D printer manufacturers have integrated different making tools into their devices, but the new Versa3D from CreateAll seems to go a lot farther.

This is no mere hobby machine, but is designed for professional use.

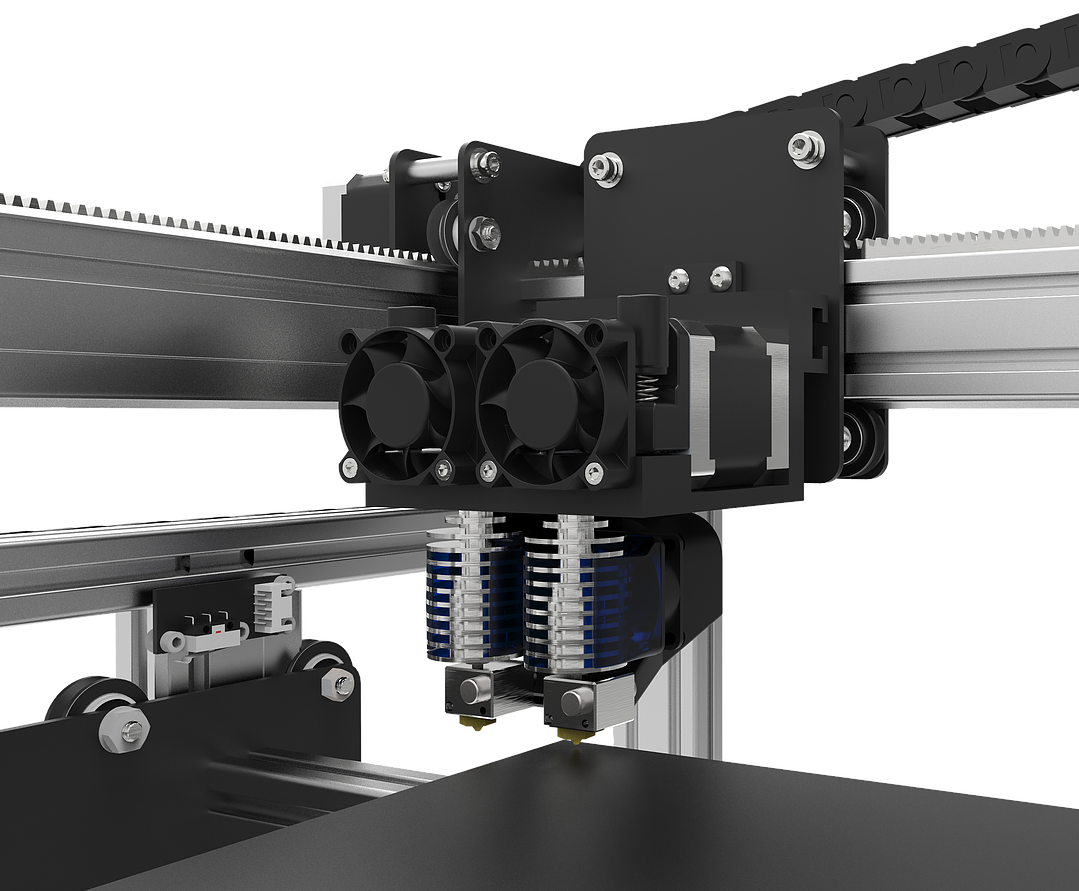

Yes, it’s a 3D printer, and a dual extruder version at that, but there is more to the story. The Versa3D includes a CNC milling toolhead as well as a laser toolhead for engraving and cutting.

There are a couple of machines that integrate similar functions, but this is where CreateAll’s product differs. Let’s look at how they implement these features.

The 3D printing subsystem includes all-metal E3D extruders, capable of highly reliable 3D printing of multiple materials, well beyond ABS and PLA, up to 300C. Of course, there is a heated print surface, too.

The build plate is auto leveling, but uses a LIDAR system, something I’ve not seen before in any other 3D printing machine. They explain:

With the help of a sophisticated firmware, bed leveling is no longer routine for 3D printing. Using a lidar sensor system, the firmware is able to measure distances and compensate for any variations all automatically. This improves the accuracy of the prints and helps with bed adhesion.

They’re also including an extruder fan that permits the use of additional materials that require immediate cooling after extrusion.

Also I should say that the build volume is pretty large: 300 x 300 x 220mm.

The milling toolhead is powerful, at 300W and should be able to slice through a good selection of materials. CreateAll says it runs silently, but that’s only the motor; milling is inherently a loud process. Messy too.

The milling toolhead uses a rack and pinion motion system instead of the more typical belt and pulleys. This is critically important when you’re trying to push the milling head through a hard chunk of material.

The LIDAR system used for bed leveling is also used by the milling subsystem to detect the edges of the material. This should simplify usage procedures and produce more accurate results.

The milling subsystem uses a T-slot bed, meaning you will have plenty of opportunities to secure the milled material before starting the process. This, again, is critically important: if material is unsecured, you could easily find a chuck of two-by-four in the side of your head, as the 300W mill could kick it out unexpectedly.

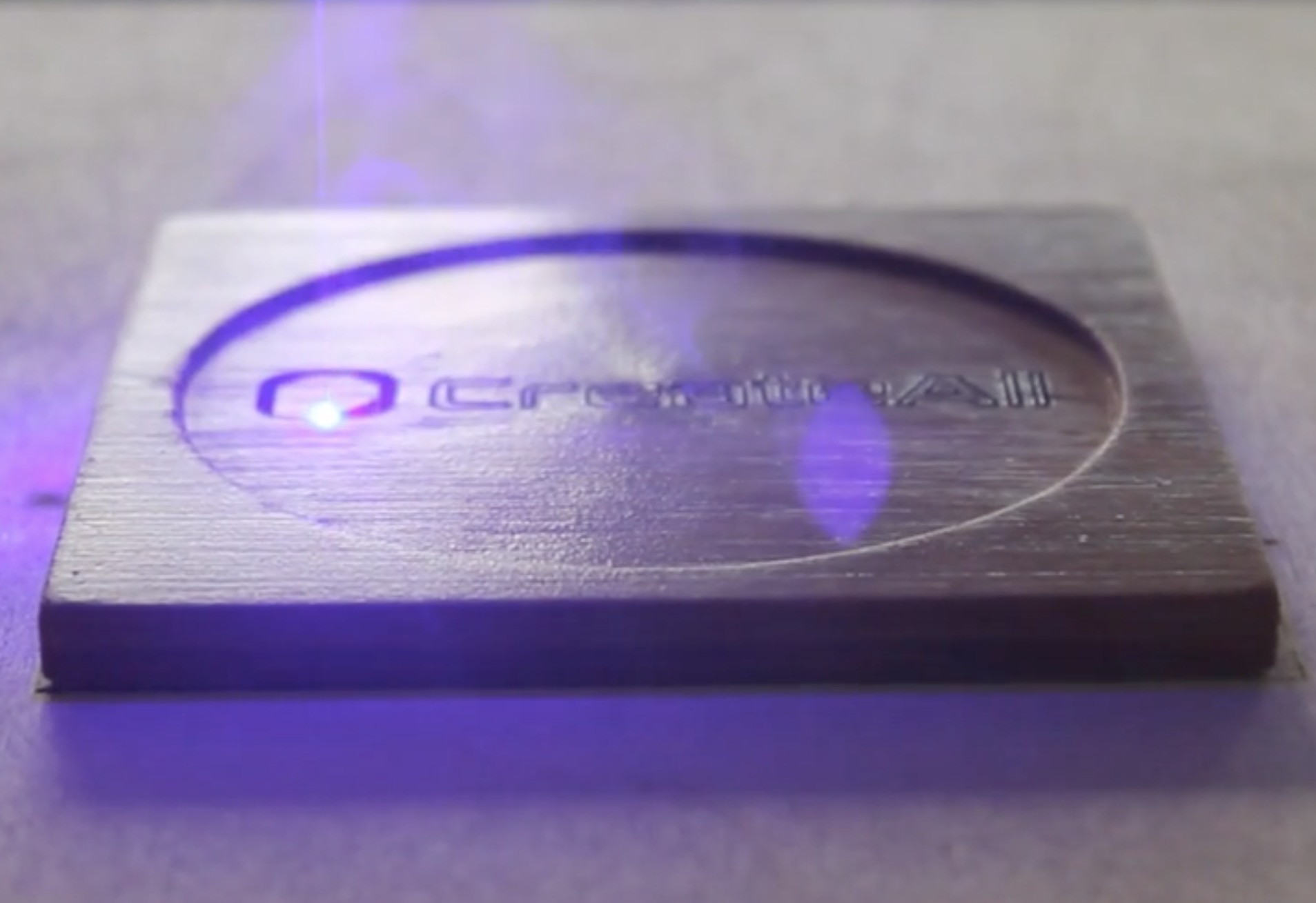

The 2.5W laser is of similar power to other units, and is far less powerful than you’d find in typical table-sized laser cutters, which are often 20W, 40W or even higher powers. However, they say it is sufficient, with “impressive cutting and engraving power”. I suspect you’d have to make the movements very slow to achieve this.

However, the laser subsystem has several interesting advantages. First, it has an adjustable focus, meaning you should be able to laser objects of different sizes effectively without having to position them precisely at the laser focus manually.

Another very interesting laser feature is the ability to engrave in the Z-axis. Typically laser functions operate over a 2D plane, but the Versa3D is able to move up and down over a 75mm window during operation. Again, this could simplify workflow by reducing the number of laser jobs for a complex object.

If that’s not enough, the machine also includes on-board 3D print slicing and the ability to monitor and control operations remotely through a web app.

This machine definitely looks like it could easily fit within any workshop and provide powerful capabilities.

For now, however, it’s available for pre-order on Kickstarter, where they are asking only USD3,499 for a complete system if you get in early.

As good as this looks, however, as of this writing only a handful of units have been ordered and they are nowhere near their goal of USD$100,000. It would be shame if this unique product doesn’t get funded, but in my opinion, it’s unique features should push it forward.

Via CreateAll and Kickstarter