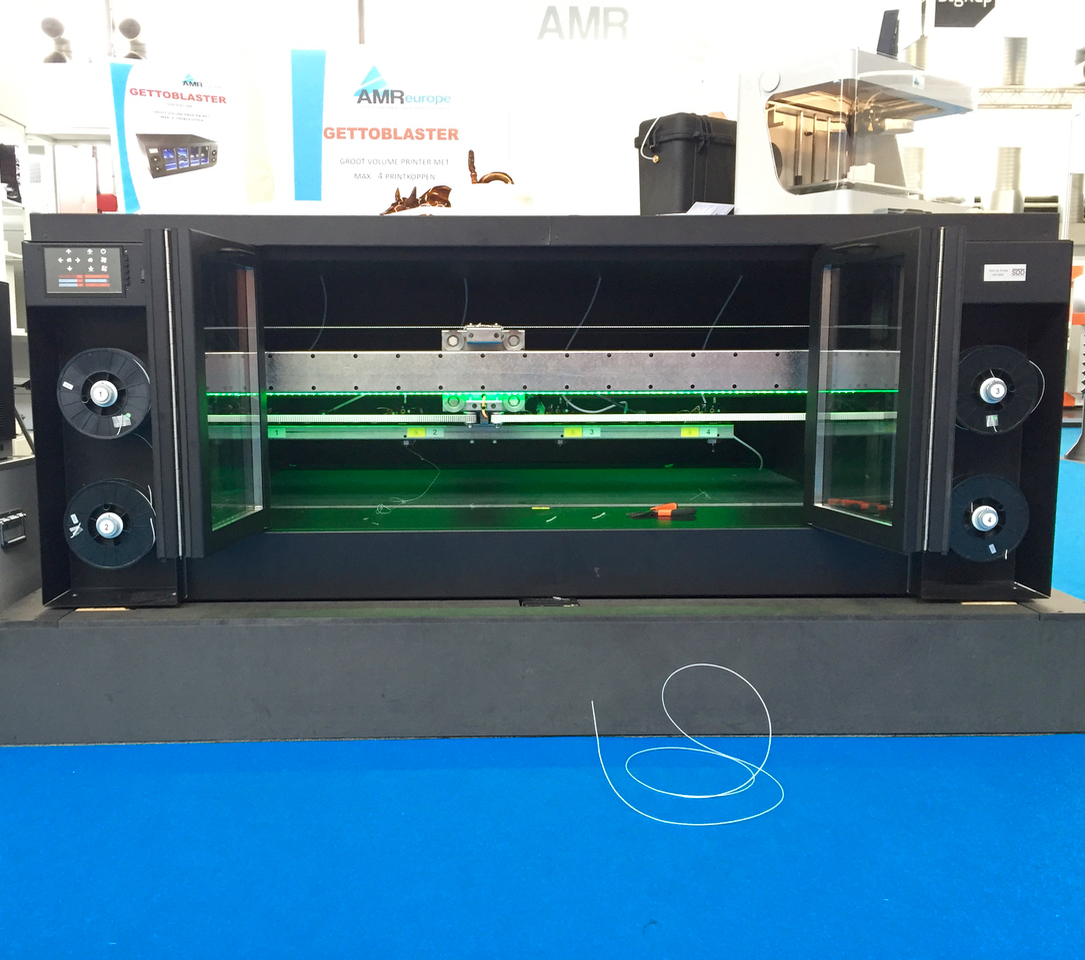

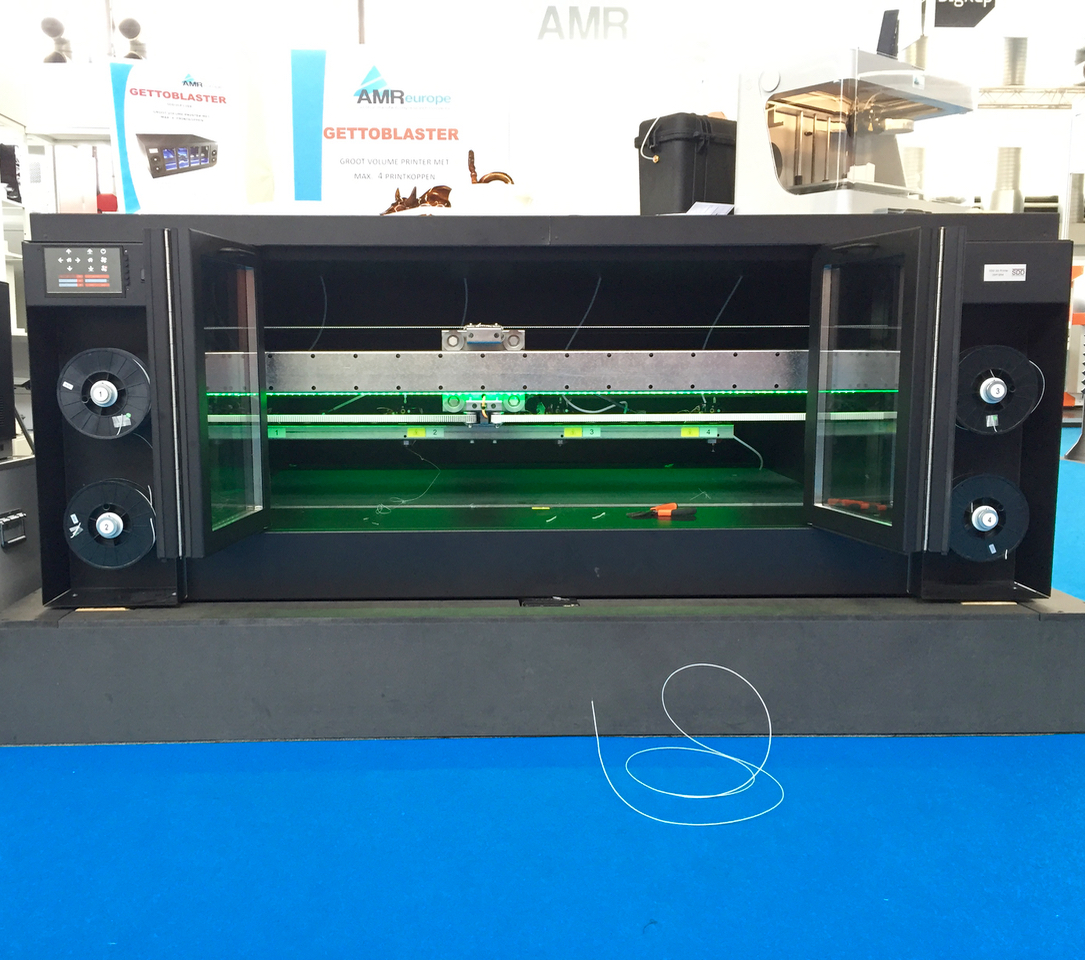

While wandering about the AMShow Europe last week our team almost missed the gigantic 3DP1204 from Netherlands-based SDD (“Smart Dedicated Design”), also known as the “Gettoblaster”.

Why did we almost miss it? Because it’s so unreasonably large you don’t “see” it as a 3D printer. I thought it was a display counter. Nope, it’s actually a huge – and I mean HUGE – 3D printer.

It’s made by Dutch company “SDD”, who normally produce equipment for graphics production. Evidently they produced this machine, the 3DP1204, as an internal project to assist them in producing components for their original product line.

However, it’s proven so successful they’ve decided to launch it as its own product and have thus entered the 3D printing market.

It’s called the “Gettoblaster” because it looks like one from the front, with the input filament spools appearing as speakers.

But from there it has nothing to do with audio, and you certainly cannot carry this machine on your shoulder at the beach.

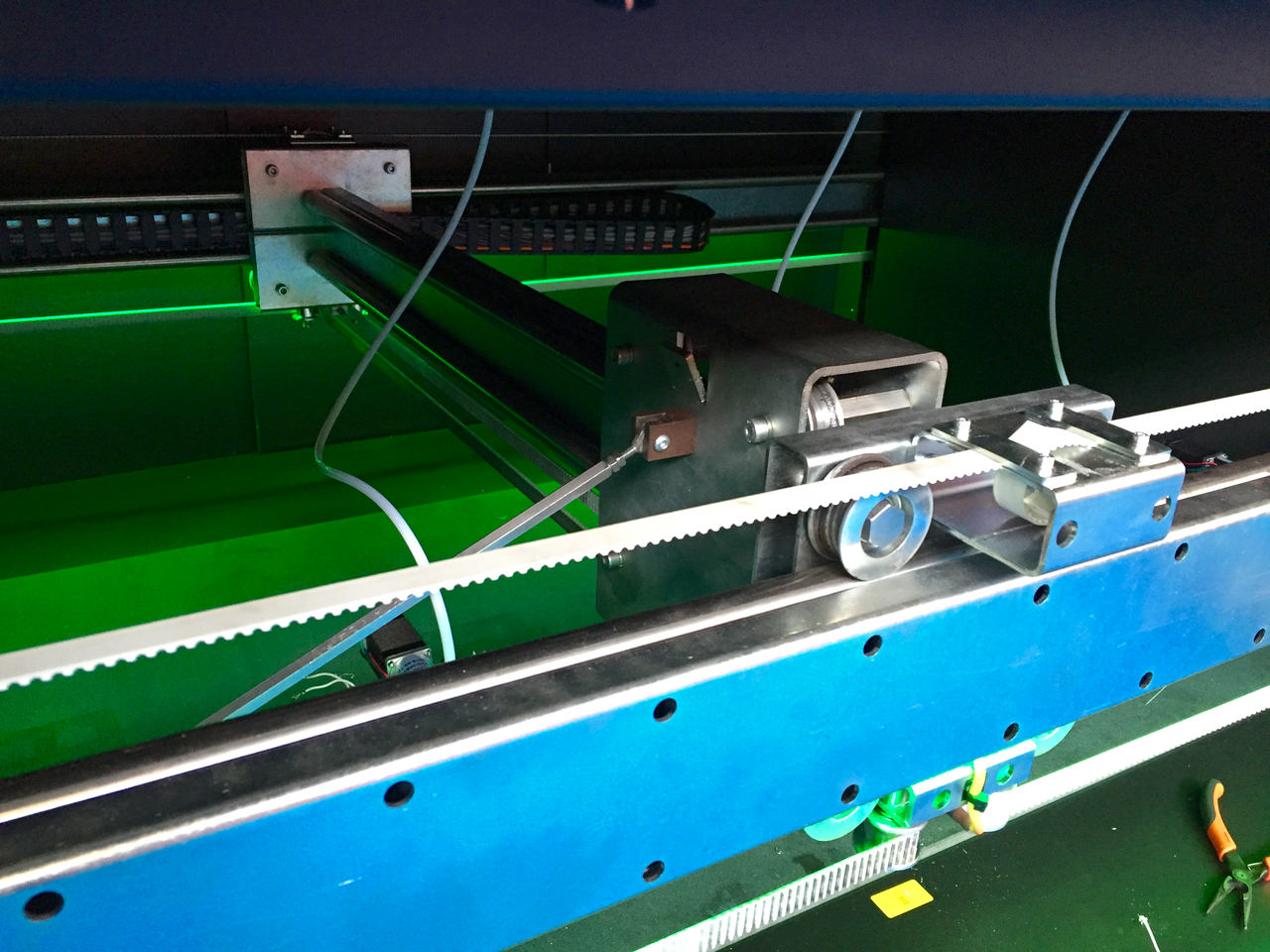

So how big is this machine? It has a build volume large enough to fit a small person or two inside, although it is curiously long and not tall. By numbers, the entire build volume is apparently close to 1200 x 600 x 300mm, and that’s on a 50mm solid granite build platform that’s heated precisely to the same temperature over the entire space.

The machine also includes a number of convenience features, such as an integrated webcam, integrated slicer and browser-based remote operations capability. It also detects “out of filament” situations and pauses the machine for operator intervention.

But this is where it gets really interesting. You can, of course, print a single object of that size. But you can also 3D print more than one object: the 3DP1204 has four extruders! They can be engaged in several ways:

- One single large object covering the entire build volume

- Two objects each covering about half the build volume

- Three objects

- Maximum four objects

The 3DP1204 can also use a variety of materials, making this a very attractive machine for those companies seeking a method of making multiple large objects simultaneously.

While the spools on the beta test machine shown above appear to be small 1kg spools (and they are), they are likely too small to be used in production for such large prints. We were told they expect to accommodate much larger spools on future versions of the machine – and may even move to very inexpensive pellet materials in the future.

Currently the machine is in beta testing at a select number of sites, and the company expects to sell it for around €140,000 (USD$156,000).

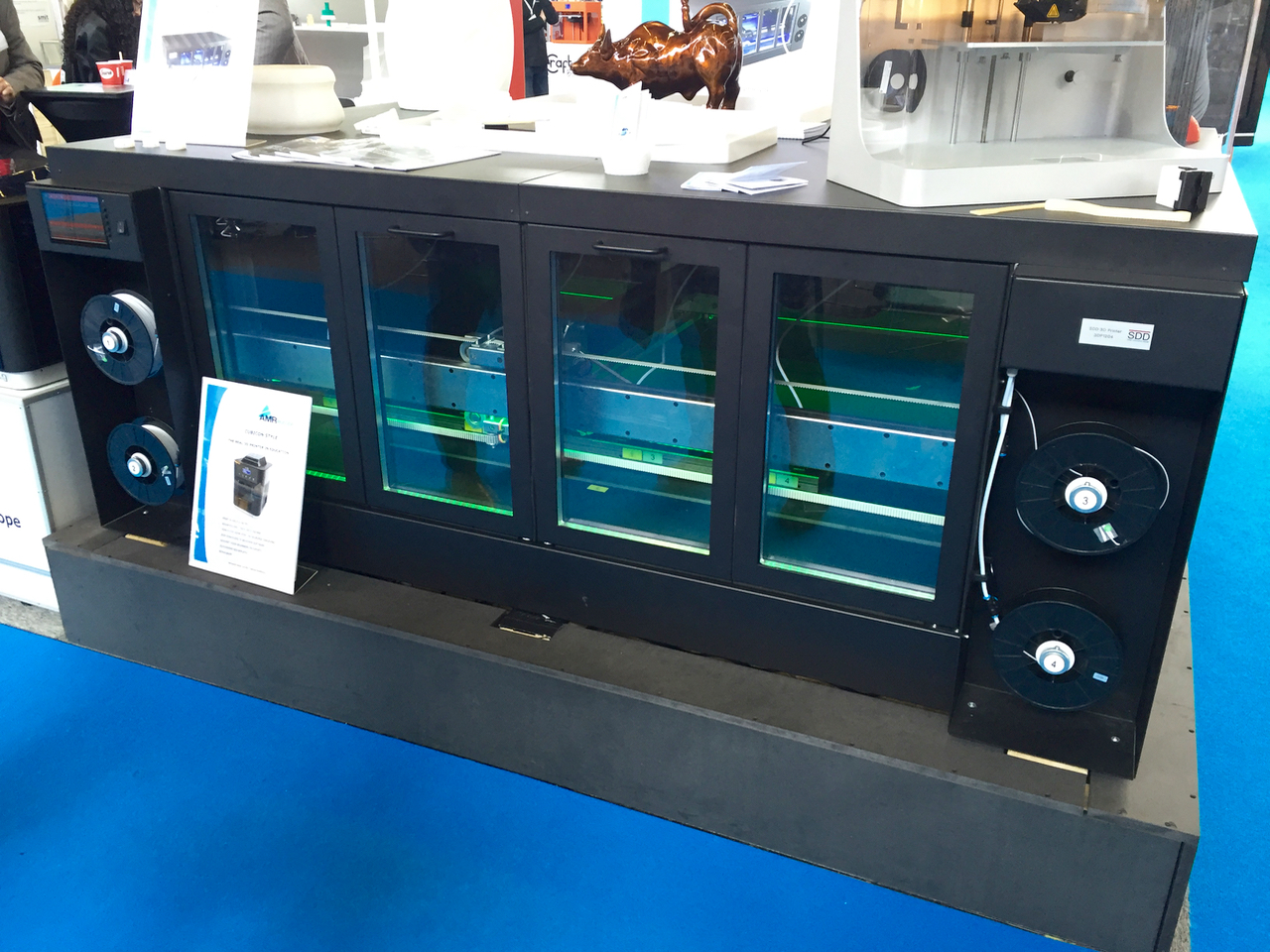

And finally, there is one major secret about this incredible machine: it’s STACKABLE!

The top of this machine is flat and can accommodate at least two more on top, making a very dense low-volume production footprint for a small workshop. I can imagine a 3 x 2 meter area rapidly printing perhaps sixteen large plastic objects simultaneously!

Via SDD