A few months ago, Stratasys announced one of the most powerful 3D printers ever, the J750. But how can you actually use one?

While the J750 can perform feats of 3D printing unknown in every other machine, it is a rather new and expensive product. So far, my understanding is that the few devices that have been placed in the field have tended to be “internal” machines used only by their owners, or consumer-oriented 3D print services.

Thus, if you are a business, perhaps a product designer or manufacturer seeking J750 prints, you could have difficulty unless you buy a J750 for your own use. And that could be well beyond your budget and operational capability.

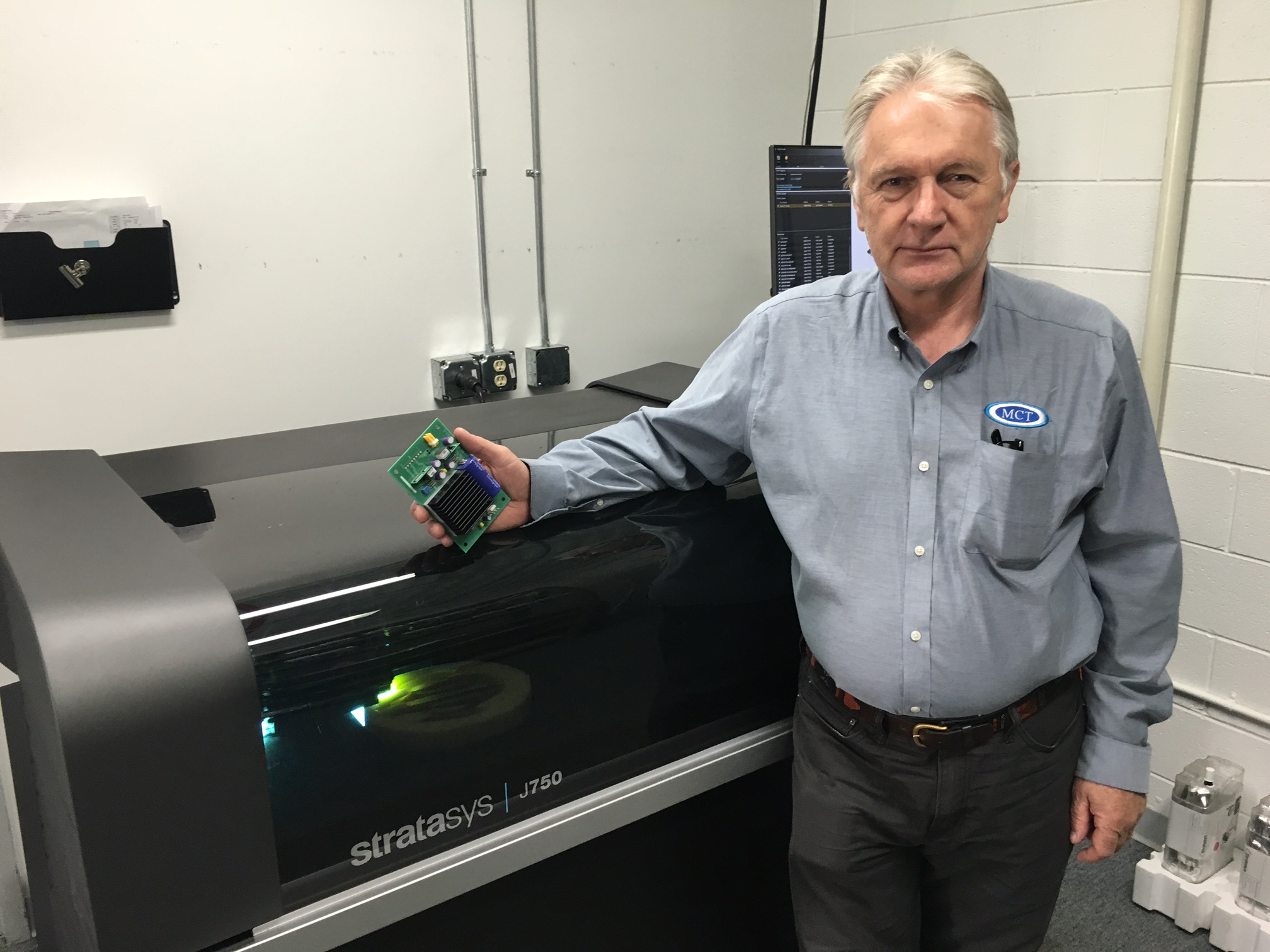

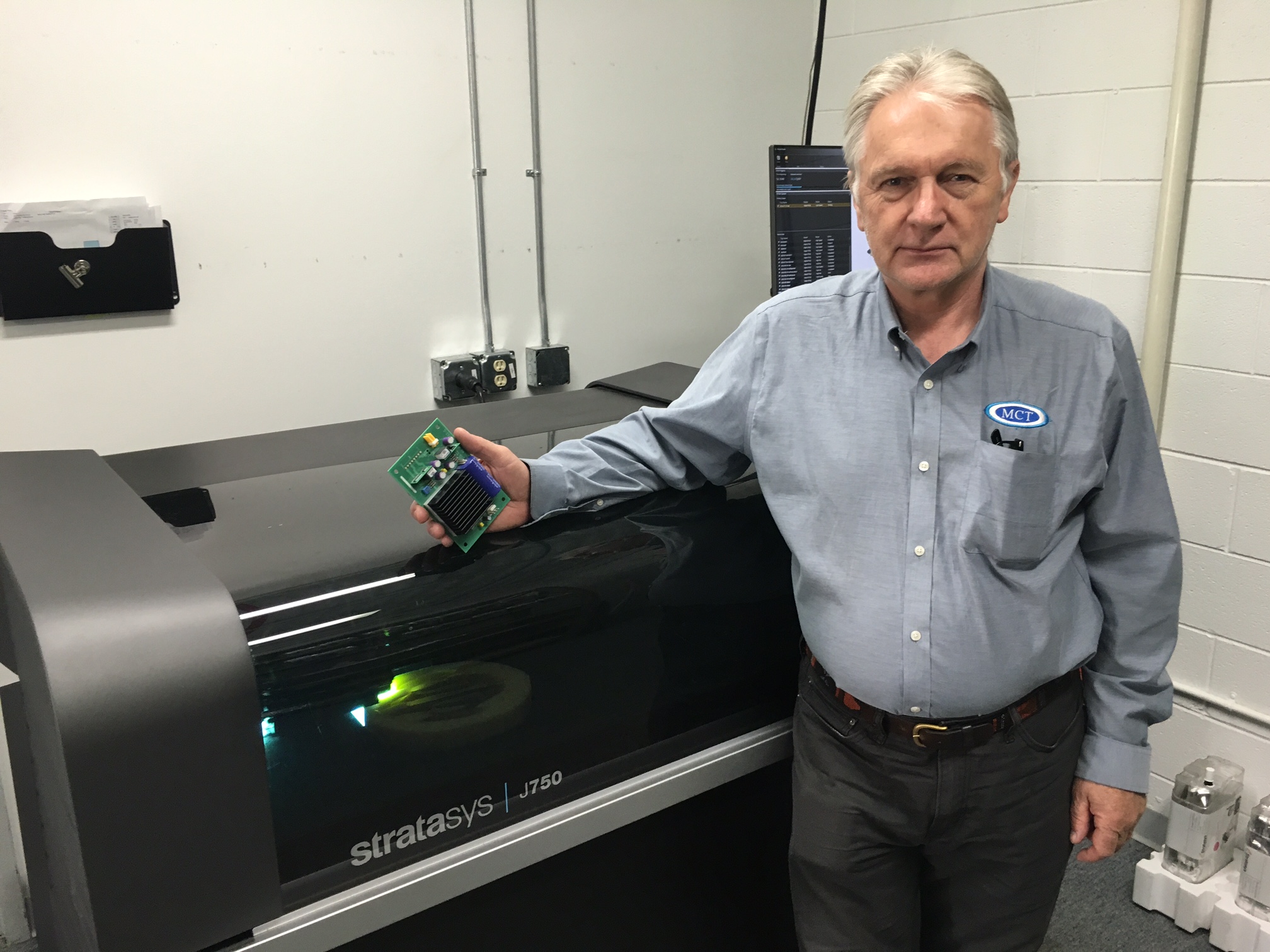

But don’t despair – we found one! It turns out that Midwest Composite Technologies of Wisconsin actually has a working J750 ready to accept B2B print requests for near-production ready color parts.

To find out more about the new J750 service, we spoke with Midwest’s CEO, Helmut Keidl:

Fabbaloo: When did you first learn about the J750 and what was your first thought?

Helmut Keidl: I first learned of the J750 January of this year, it was presented to us under non-disclosure at our facility here in Hartland, WI. I was very excited about the machine because it contained several long awaited features: redesigned heads, 6 materials at once, faster, and full color. Full color was definitely the most exciting because it was difficult to tell that the object they were making were printed.

Fabbaloo: The J750 provides some very new capabilities; do you anticipate your clients having any trouble making use of them? Or will they require some process or software changes?

Helmut Keidl: The J750 still uses STL files but uses a VRML for prints with image mapping and color. VRML is an STL file with embedded color data. Color and image mapped files are something new to most of our clients. The engineering CAD software generally can not output an image map, this has to be done in a secondary program. What we have done is added the secondary software so that we can help the customers that do not have the access or ability to create these files.

Fabbaloo: How long have you been using the J750? Has it met your expectations? Has there been any unexpected challenges with the new machine?

Helmut Keidl: We have had the J750 for 2 months now. I am truly impressed with it’s full color abilities, in a time when additive machine manufacturers are trying to create production quality physical properties, the J750’s focus has been on realism. . It makes a realistic looking part, it can be hard to tell it is not real.

Fabbaloo: Have customers caught on to full color? Are you seeing many prints come through your business to be made on the J750?

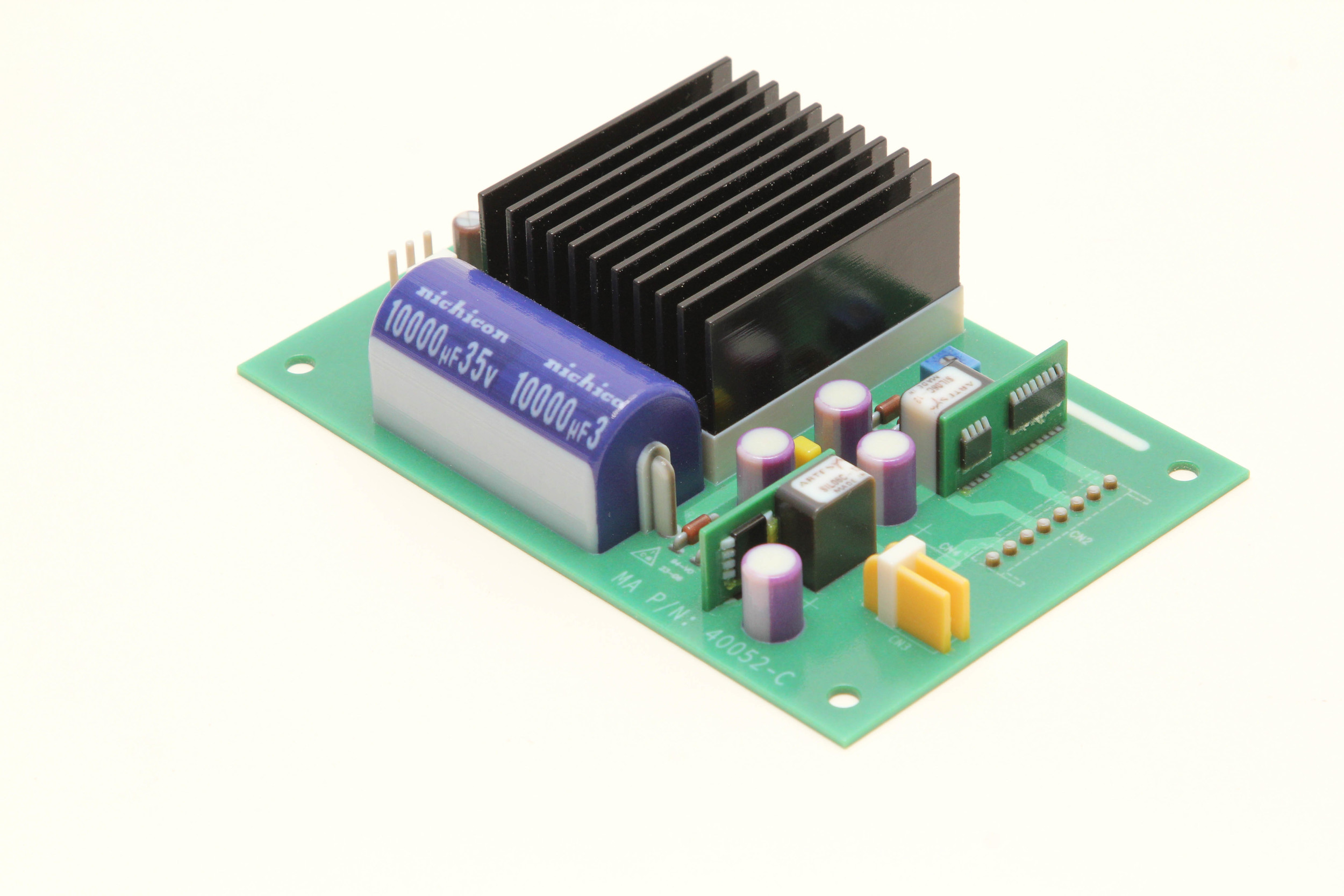

Helmut Keidl: I don’t think most people really understand the actual capabilities of the machine. The J750 is capable of making finished looking models straight out of the machine with minimal post processing. This is a huge time savings. This can generally save a day or two on development time, there is no painting, prepping, masking, or decals. The final part looks production quality.

Fabbaloo: It’s been said that prints from the J750 are “near production quality”. What kind of prints have your customers been doing? Production or Prototype? Do you see this changing as they get more familiar with the J750?

Helmut Keidl: The prints from the J750 “appear” production quality, the full color parts generally do not meet the functional properties of production parts. The J750 can do 2 things that no other printer can do right now: Full rich and vibrant color parts, and colored soft durometer and over molded parts. This machine is a tool and like every other tool, you need to know how and when to use it. The hurdle we face with all of our customers is to educate them on the capabilities and how many of their own projects can benefit from this new technology.

Note: the images in this post you’ve been seeing are all printed samples produced by Midwest to illustrate the capability of the J750. They’re extremely lifelike, and therefore are ready-made for immediate product testing in many cases without any requirement for further processing after printing.

It seems that Midwest has figured out how to use the new machine and could be a good option if you want to try out full-color prototypes and end user test-worthy parts.