The excitement that used to come with each new “revolutionary” desktop 3D printer a few years ago has since quieted down in a major way.

While technologies like HP’s Multi Jet Fusion and Carbon’s CLIP can hold their own and even generate mainstream news coverage, these are geared towards professionals at price points that are generally only accessible by an industrial firm rather than a casual garage maker.

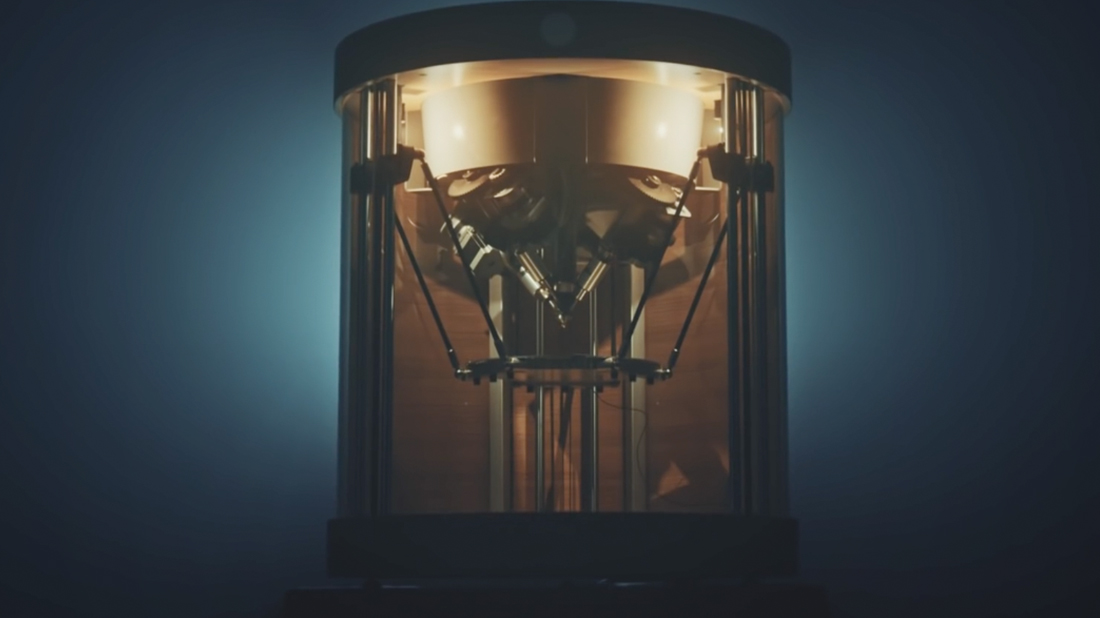

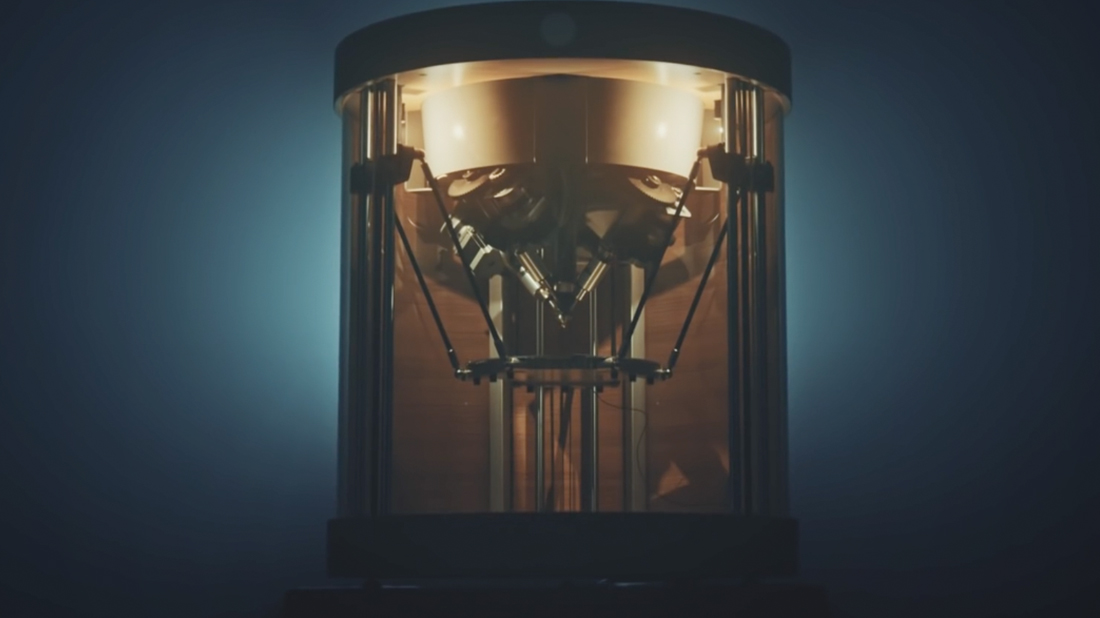

Which is why the recently announced Pam 3D printer from Pollen presents a curious case study into what the near future might hold for desktop 3D printers as consumer interest wanes while the industry itself – and professional usage – continues to grow.

Priced too steep for consumers yet at a bargain compared to typical industrial 3D printers, the $9,000 (presale price before hiking up to $18,000) multi-material FDM 3D printer promises to print thermoplastics, silicones, composites, filled materials and more with industrial grade quality using a variety of material pellets rather than filaments or powders. According to the company, these resulting prints are capable of having various flexibility, elasticity, strength, transparency and colors characteristics for rapid prototyping and short run manufacturing. As a full-stack printing ecosystem, Pam also includes software built into the printer that connects via WiFi to the company’s own Cloud-based Honeyprint software.

Read more at SolidSmack.com