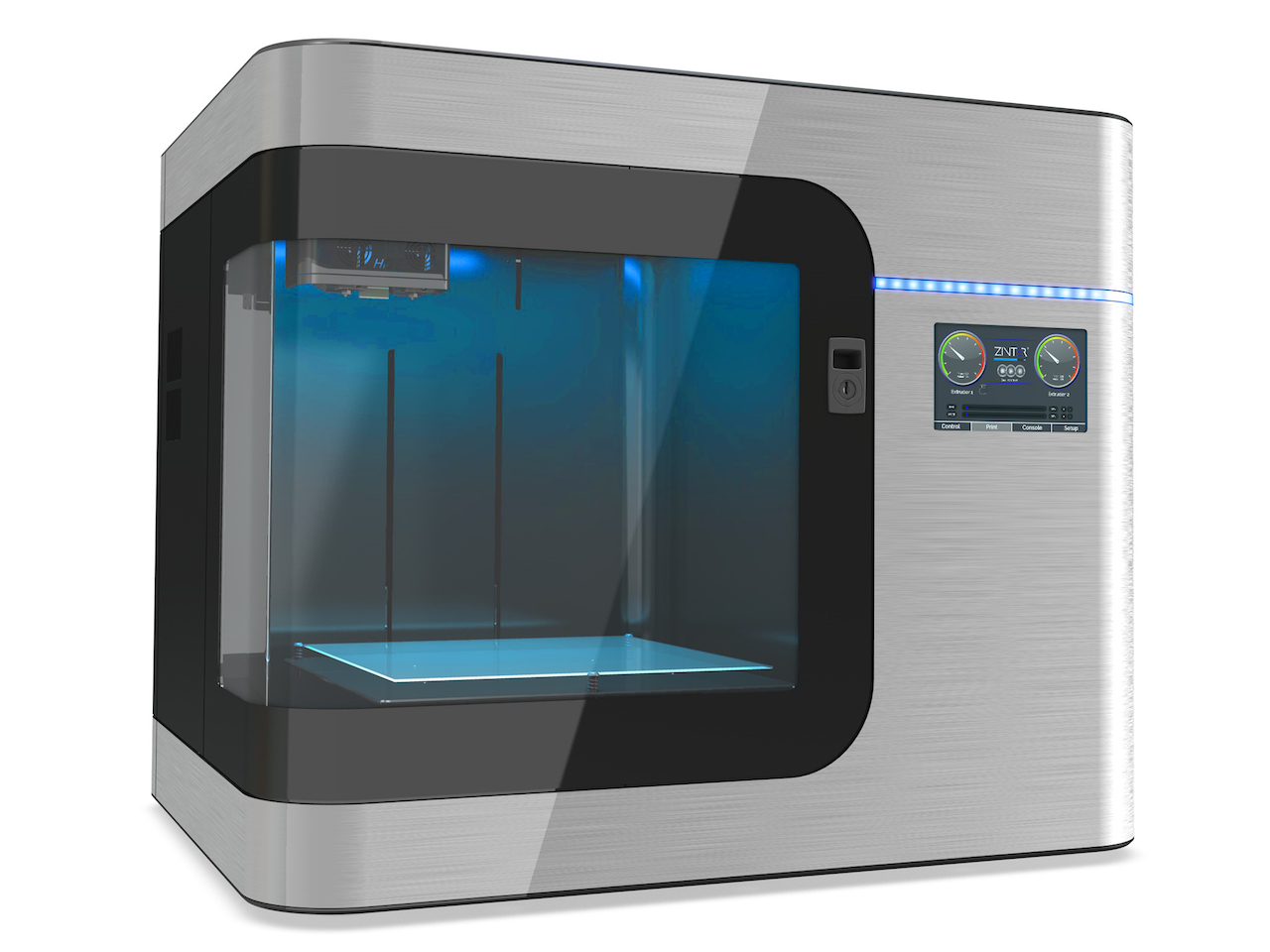

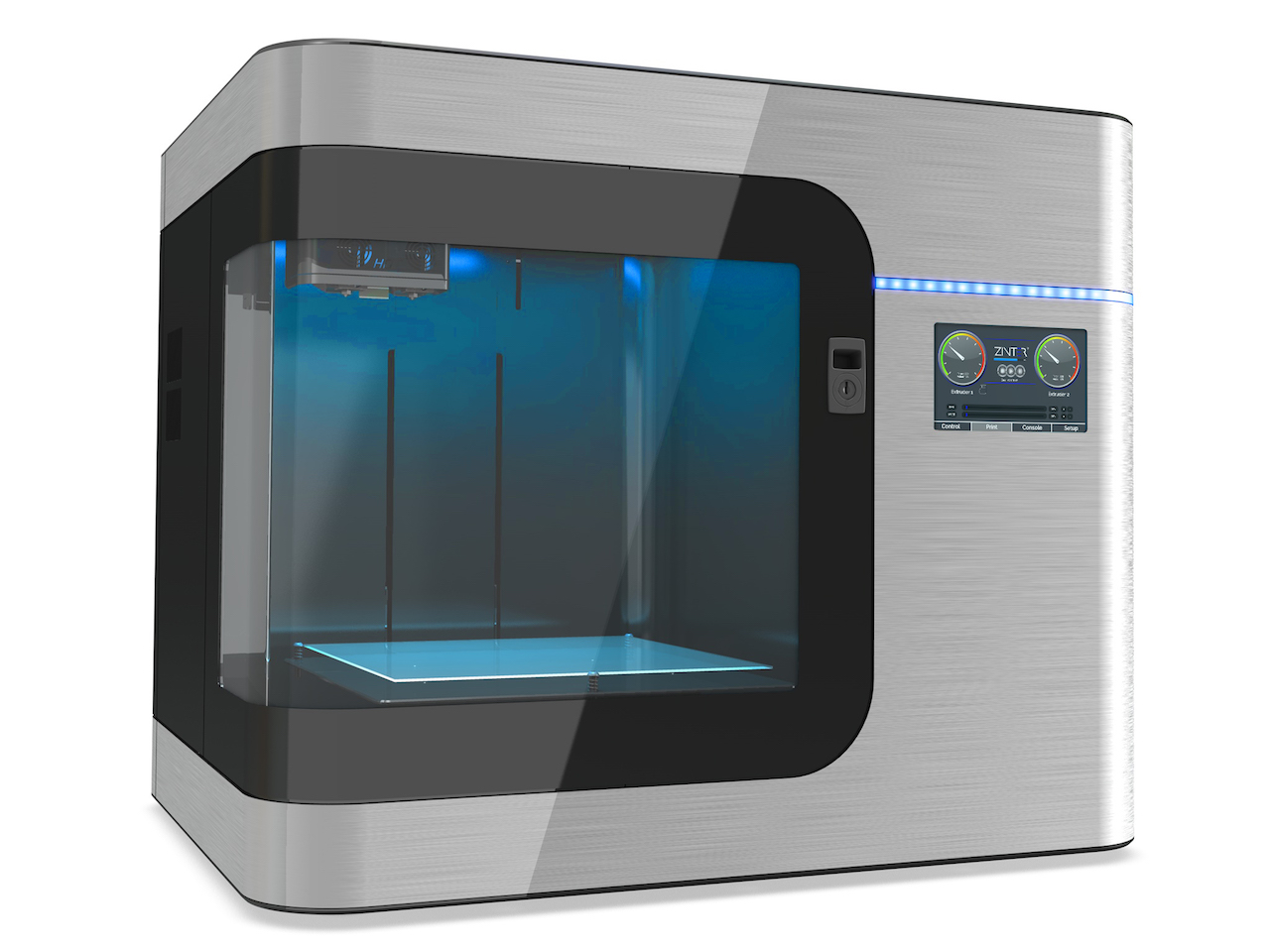

IonCore has launched a new professional desktop 3D printer, the Zinter Pro II.

If you’re not familiar with IonCore, they’re one of the smart 3D printing companies. Yes, they make desktop 3D printers, but right from the start they’ve been specifically addressing the professional market, producing – and optimizing for – industry clients. This is quite a contrast to the many desktop 3D printer companies who hoped to capitalize on the consumer 3D printing craze and now must somehow switch their business model to focus on professionals; IonCore has been there all along.

Their previous machine, the Zinter Pro, released more than two years ago offered capabilities suitable for business, particularly the ability to reliably 3D print in multiple materials, materials of interest to product designers, like nylon and polycarbonate. At that time there were far fewer machines designed to print these materials, and often businesses simply purchased much higher-priced to gain the capabilities present in the Zinter Pro.

Now IonCore has released the Zinter Pro II. The build volume of the II is up substantially, with a 300mm cubed volume as opposed to the mere 200mm cubed volume of the Pro. The new machine also includes high accuracy linear rails and carriages to smooth movements and increase reliability.

Aside from the significantly increased build volume, the major changes are on the outside. While the machine retains the unique corner-opening door found on the Pro, the case now has a sleek metal finish.

Also changed is the control panel, which was rudimentary on the Pro. The Pro II includes a proper color touch screen that matches the case styling well.

Another interesting change is that filament spools are now stowed on the inside of the machine in a special embedded cabinet. I believe this is important as it strongly reduces the possibility of dust contamination landing on the filament, which of course can lead to clogging as dust accumulates in the nozzle.

There is also an “active cooling system” that enables precise control of post extrusion cooling, layer by layer. They say: “unsupported overhangs are now entirely possible”. I’m not sure how that can work in all situations, but it sounds interesting.

The machine also includes a rather sophisticated “Auto Bed Leveling Compensation” feature, in which infrared sensors continually monitor the state of the print surface and adjust accordingly to ensure correct prints.

While IonCore has worked closely with industry for their previous models, it seems they’re also opening up the possibility of the Pro II being used by education. Why do I think so? Because they’ve added two specific features:

The fancy door locks during printing to ensure curious students don’t get their fingers caught or burned in the print enclosure

An integrated air filter system removes odors generated during printing. I’m not sure if this system removes nanoparticles, but at least it’s a start

The Zinter Pro II is available for order and is priced somewhat higher than the Pro’s £2,999 (USD$3,950) at £3,495 (USD$4,600).

But here’s a special treat for you: Apparently IonCore is providing a healthy discount of 15% off these prices if you purchase an order before midnight (GMT) on August 5th. To get the discount, you must specify the code “XPY767YPP” when checking out of their online ordering system.

Via IonCore