We spoke with BigRep CEO Rene Gurka recently and learned more about the company’s strategy and upcoming moves.

BigRep, you may recall, was perhaps the first company to take the filament extrusion technology to a massive scale, producing a huge 3D printer capable of printing a meter on a side. The original machine was remarkably similar to its smaller cousins, but was simply much larger.

The market for such equipment was at first considered to be for artists who sought ways to 3D print large sculptures inexpensively (or at least compared to the industrial 3D printer of the day, which were the only ones capable of such sizes.) But as BigRep and similar companies evolved, the companies discovered there was a market among industry for large 3D prints, perhaps again due to the cost of using the higher-end equipment.

Since then, BigRep has gradually increased the capabilities of their machine, now called the BigRep One. They’ve also grown to a team of 50 and have shipped over 100 units.

Gurka explained their focus is now “all about throughput”. And this make sense. If you’re familiar with the speeds of the much smaller desktop 3D printers, you’ll be aware of the hours you wait for even a small object. Imagine how long you’d wait for a meter-sized print and you’ll understand Gurka’s concern.

Another concern with large, lengthy prints is the requirement for operator intervention. A long print will require a lot of plastic, and such prints require an operator to frequently swap in a fresh spool of material. This causes delays, especially when the operator isn’t present and the machine pauses, waiting for more material.

BigRep has taken several steps to address the throughput problem.

First, they’ve introduced different nozzle sizes. A larger diameter nozzle will extrude more plastic at a time, speeding up prints. This can be quite significant.

Gurka says their 1.0mm nozzle will deliver an amazing 2.5kg per day. (Remember that if you’re using 1kg spools, this means two and a half spool swaps per day).

But most interesting is their new 2.0mm nozzle. This feature enables the BigRep One to 3D print up to 10.0kg per day! The resolution won’t be nearly as fine as you’d see in a standard 0.4mm nozzle, but that really doesn’t matter for such large objects: the layer lines are lost in your vision because you typically don’t look so closely at a large object.

But there’s an issue with this: if you’re 3D printing 10kg per day, you would expect to be swapping 1kg spools every other hour all day long. That would require a lot of operational labor. Gurka says their long-term goal is 24 by 7 unattended operations.

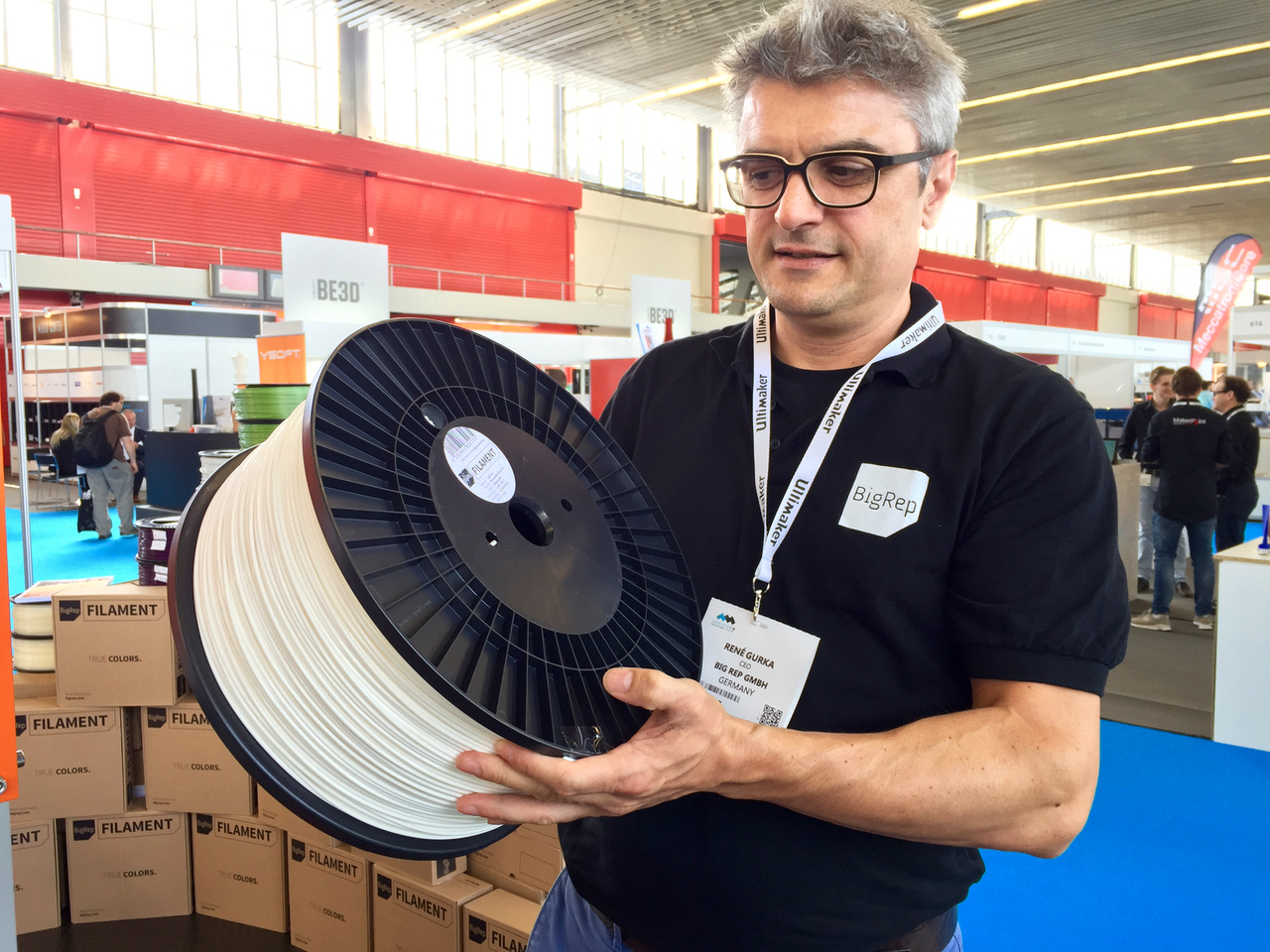

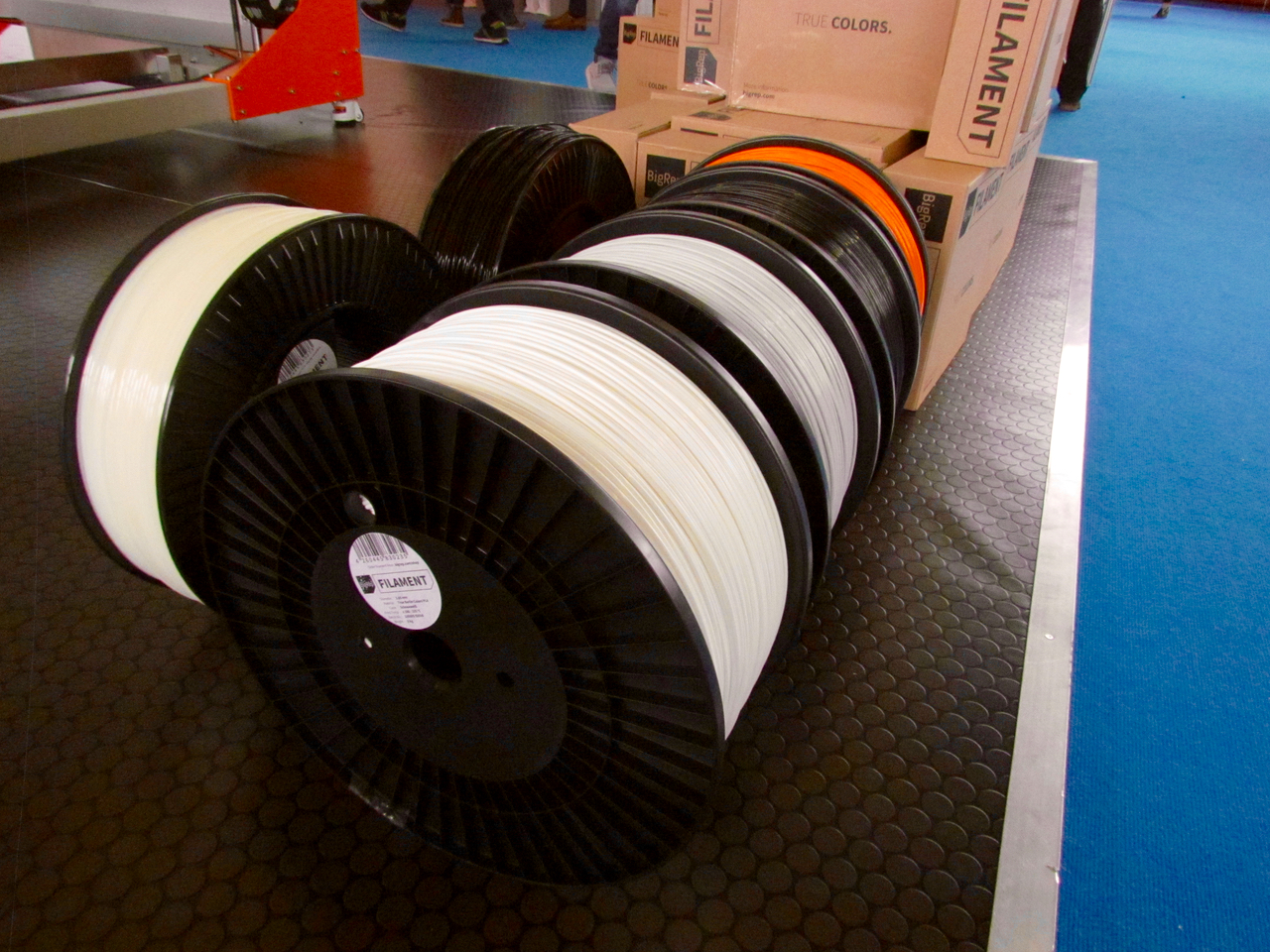

One big step along that road is to employ much larger filament spools. At top you can see Gurka holding a 5kg spool, and I believe they would like to use even larger spools. To make use of such gigantic spools feasible, the BigRep One now includes powered spool rollers shown here.

Long term, I suspect BigRep will attempt to use the far more inexpensive plastic pellets instead of filament. That would significantly lessen the cost of operating a large-format 3D printer like the BigRep One.

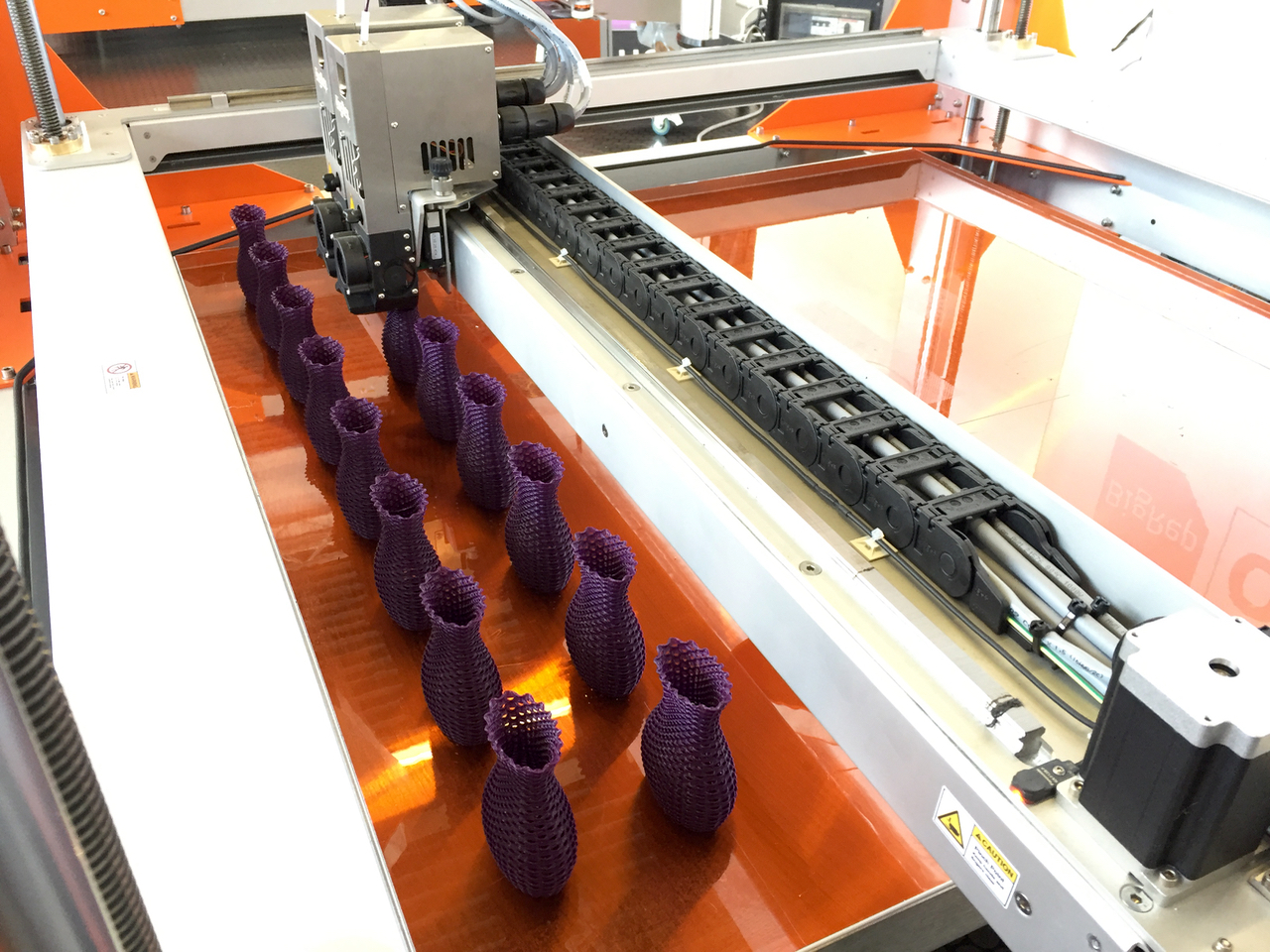

A very interesting feature on the BigRep One is its ability to print multiple objects separately. Normally objects are all printed at once, layer by layer. However, in a long print, you risk losing them all if something goes wrong. So, again in the efforts to achieve efficiency, the BigRep One can print single objects, one at a time as shown here. Thus, if something goes afoul, you don’t lose the previously printed objects.

Another very interesting strategy now employed by BigRep is the use of plastics. In an open-to-air machine like the BigRep One, certain plastics like ABS are subject to warping, and severely so at the large print sizes the BigRep One is capable of producing.

Smaller machines overcome this by enclosing the print chamber to capture heat and prevent warping through temperature. A couple of years ago, BigRep showed publicly a prototype of an enclosed version, which used this same principle, shown here.

However, Gurka says this is no longer their strategy. Instead, they’re using chemistry to solve the problem. It turns out it’s far cheaper to simply use a plastic that is not subject to warping like ABS, and so they’re in the midst of developing one. Gurka explains that it will be a “high temp PLA, like ABS”.

It’s fascinating to see how the original idea of a plastic extrusion 3D printer has been scaled up to such a sophisticated device as the BigRep One. But that’s definitely not the end of the story for BigREp.

Via BigRep