You might think you need to fuel a 3D printer with plastic or resin and you’re good to go. But there’s something else you should be very concerned about: power.

Yes, obviously electricity is required to run a 3D printer, but there are two aspects of power that are critical.

One you’ll probably guess is uninterruptibility. There’s nothing worse than having the power fail during a very long – and expensive – 3D print job. This causes not only a loss of (probably) expensive 3D print material, but also long delays. Delays in business could be fatal, depending on the arrangements with the customer.

There are two solutions to this dilemma. One, which I’ve seen a couple of 3D printers implement recently, is to include a small battery system on board the 3D printer itself. These systems detect that power is lost and will direct the machine to shut down gracefully. They’ll save the state of the machine and enable a resumption of the interrupted print job later when power resumes. One example of this is BEEVERYCREATIVE’s battery backup system, which we explained last year (be sure to watch the video where the power cable is dramatically disconnected during a print.)

Another approach to power interruption is to provide an external uninterruptible power supply system, or UPS. These are a bit more complex to implement than the on-board system describe above, because they likely have no communication with the 3D printer and are expected to supply power for the duration of the outage. In other words, the 3D printer won’t know that power is off and will continue printing. This means that the UPS must store sufficient energy to complete most print jobs.

However, as you know 3D print jobs can take an enormous amount of time to finish, many hours or even days in some cases. Those are the print jobs most critical to keep going, as you’d lost the most time and material if they fail.

Providing an external UPS with days of power could be prohibitively expensive, and likely would be used only on large-scale commercial 3D printing operations.

The other consideration with power for 3D printing is the quality of the power.

While many areas enjoy “clean” power, sometimes it isn’t. Input power can vary in voltage slightly, and this can lead to various effects on print operations.

Should the variance be sufficiently large, it could cause the electronics to fail, for example.

Variances in power quality can affect the motors within the unit as well, and possibly cause extra wear and tear on the components.

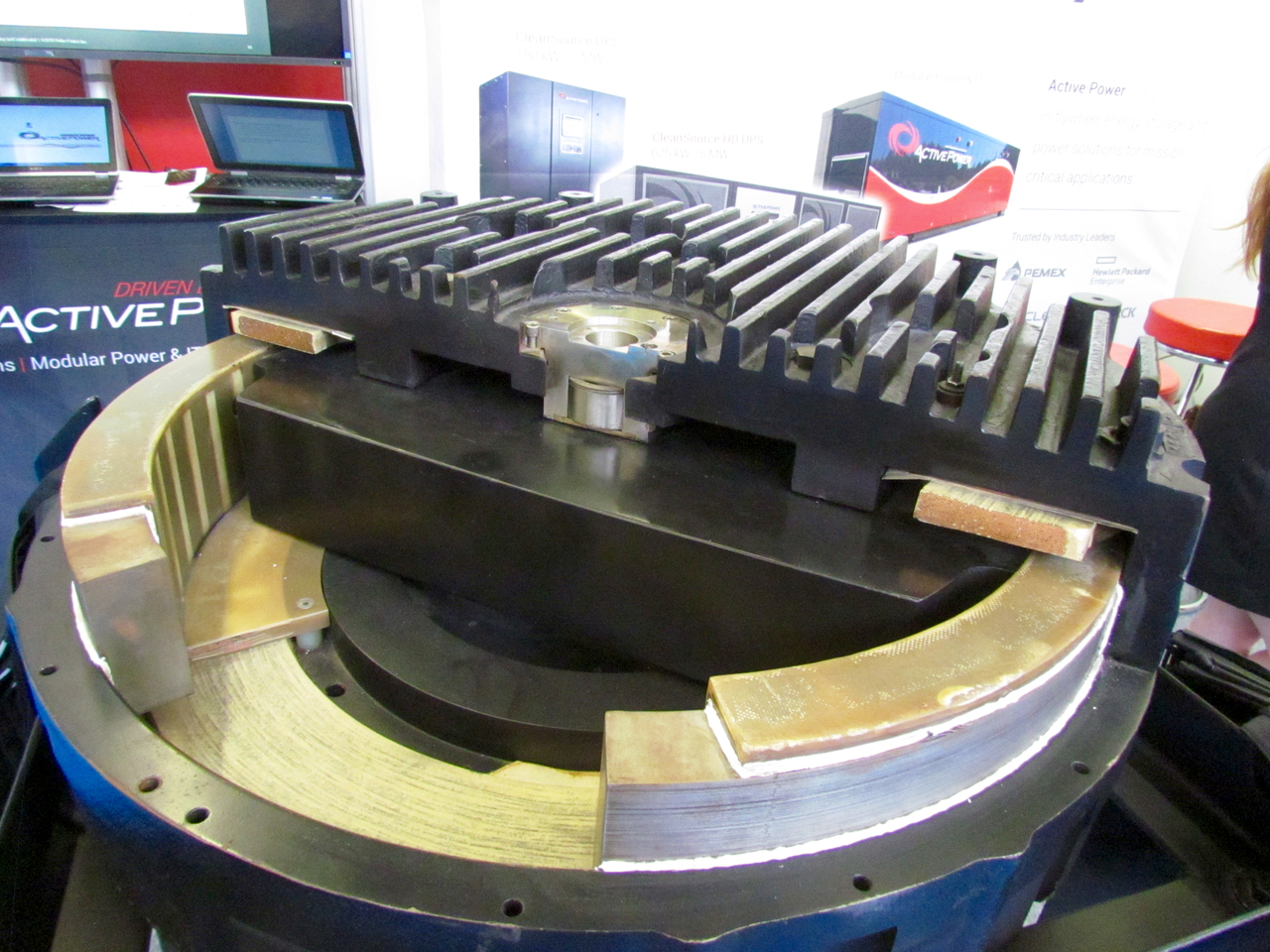

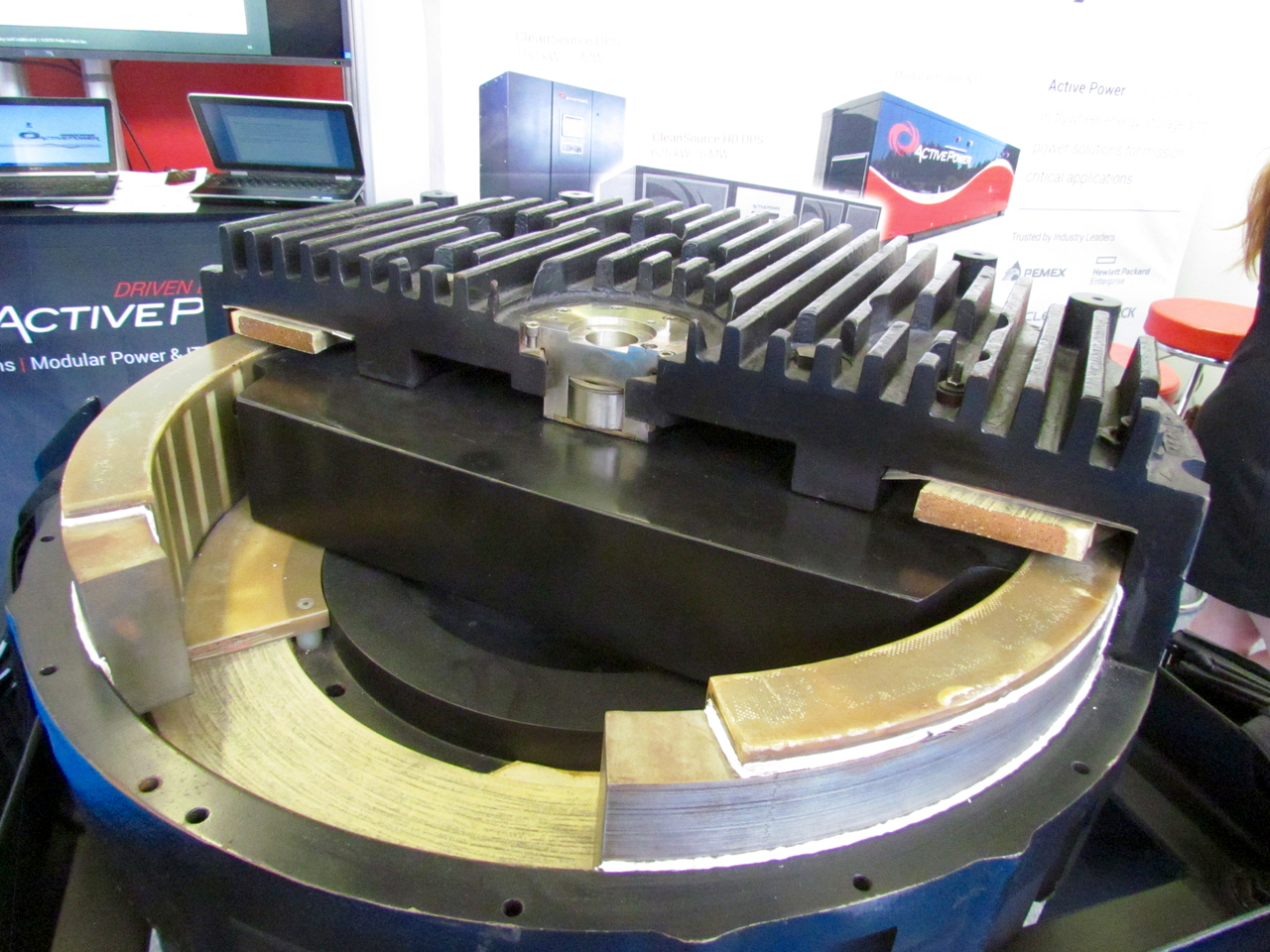

The solution to this is to provide clean power. Clean power can often be provided via a UPS that maintains levels within specific tolerances. Sometimes such systems involve flywheels that stabilize power by relying on their regular spin.

The bottom line here is that if you’re intending on running critical 3D print jobs for longer durations, you should be aware of power issues and potential solutions.