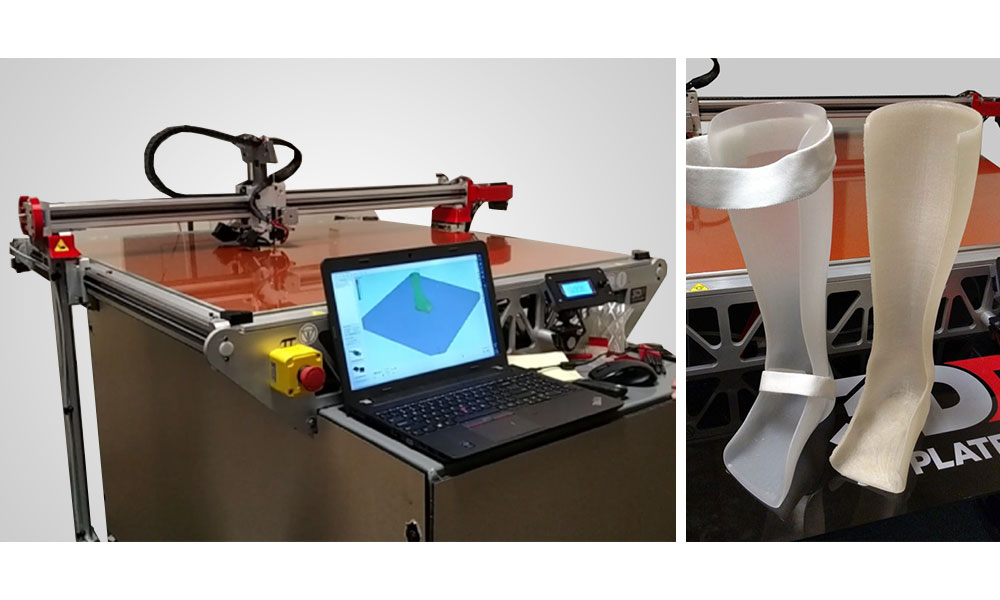

A project using 3D Platform equipment has successfully developed an interesting new 3D printing application: custom fit ankle foot orthosis, or “AFO”s.

These are like thin casts that brace an ankle to restrict motion by wrapping around the leg and foot.

The traditional approach for such devices is a lengthy series of scans, molding, vacuum forming and eventually fitting on the patient. According to 3D Platform, this can take as long as four weeks, as I expect each stage passes through different organizations.

3D Platform partnered with a group of students at Gonzaga University to short-circuit this problem by directly 3D printing a usable AFO.

The new experimental process still involves 3D scanning of the foot and lower leg, but then it’s quite different. A 3D model of the leg surface is generated with a design that provides sufficient strength and comfort for the specific patient.

Then it’s printed on a large-format 3D printer, as the AFOs must be a single part and can be as large as 18 inches (460mm). This is beyond the build volume of many 3D printers, but certainly not on 3D Platform’s massive 3D Workbench, which has a build volume of 1,000 x 1,000 x 500mm. With such a machine, you could print AFO’s for BOTH legs at the same time.

The new process can produce the custom AFO in two days or less, far faster than the traditional method.

The student researchers also had to determine which material would be best for the application. Surprisingly, they chose PLA and PETG as the most appropriate plastics for the AFOs. I would have thought ABS or Nylon might have been better, but the team evidently tested tensile strength, fatigue rating, printability and repeatability to arrive at PLA and PETG. I’m just hoping those with PLA AFOs don’t go swimming for too long!

I believe this to be an excellent application for 3D printing, not only for all the reasons above, but also because the print itself is extremely straightforward and doesn’t require a lot of material. The AFO is essentially a thin shell over top of the leg and foot with no internal material required. Therefore, fast and cheap printing, which should overcome any challenge from traditional methods.

Via 3D Platform