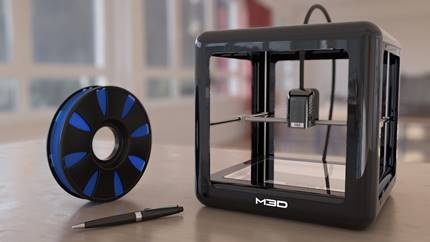

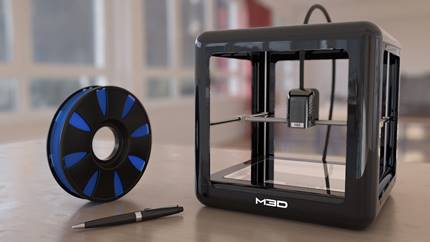

One of the most popular desktop 3D printers just got a lot better.

M3D was one of the few companies that was in the right place at the right time with the right product when they launched the Micro in 2014. Their crowdfunding campaign generated a massive USD$3.4M with which they built a company producing one of the largest-selling desktop 3D printers available.

Now, two years after the fact, the company today released a new and significantly improved machine: the M3D Pro.

The new machine is visually reminiscent of its predecessor, the Micro, in that it’s an open cubic style. The differences are in performance and capability, which I believe have largely been driven by customer requests.

The specific improvements are:

The build volume is quite a bit larger, now 198 x 183 x 183mm. Of note is that this build volume is only slightly smaller than the exterior of the machine. The design is very space-efficient.

Reliability is increased. While the machine is not fully enclosed, it does now sport a heated print surface, which should significantly reduce warping. They’ve also included a system to handle power failures: you can resume printing after a failure! This should be a standard feature on every desktop 3D printer, but still appears on only a few machines, one of which is the M3D Pro.

Reliability is also made better through the use of more than “two dozen” sensors. Evidently the M3D Pro uses sensors to calibrate the bed leveling and subsequently continuously monitor the print operation. I’m told automatic management includes monitoring and appropriately adjusting speed, position, fan speeds, filament flow rates, temperatures, and power levels. That’s a feature not seen on very many desktop 3D printers.

Flexibility is increased by including the ability to do standalone printing, without having to have a computer attached to the printer. The M3D Pro includes its own memory that quickly soaks up the print job and prints on its own thereafter.

Quality is increased, as the M3D Pro can print in layers as small as 0.025mm, on par with the best plastic extrusion machines available. Printing is at the standard 60mm per second, however.

Materials capability is significantly increased. While the Micro could handle PLA plastic, the M3D Pro can handle a wide variety of plastic filaments including not only PLA and ABS, but also exotic and composite filaments as well, due to the heated print surface and high temperature hot end (at least those up to 270C). Of course, third party materials are encouraged.

These features make the M3D Pro a desirable machine, but you may be concerned about the price. Their previous machine’s most prominent feature was its incredibly low purchase price, and you might think with such improvements they’re going to raise the price significantly – because they likely could.

Nope, they’re not. The M3D Pro will apparently be available, at least for the pre-order period, for only USD$500! That’s a great deal for a machine with such capabilities.

Will M3D sell as many of this model as they did their previous version? I’m not sure, but the signs are looking good, at least based on the specifications.

Via M3D