A new adhesive is triggered by electricity, suggesting the possibility of a new form of 3D printing.

Researchers at Nanyang Technological University in Singapore and Zhejiang University in China have developed a very unusual adhesive that cures using an application of low voltage electricity.

Currently all 3D printing technologies are based on a small set of fundamental curing technologies: photocuring (for resin-based 3D printers), heat curing (for several types of 3D printers) and chemical curing (for certain powder-based 3D printers). This discovery could result in another fundamental approach: “electrocuring”.

Here’s how they describe the process:

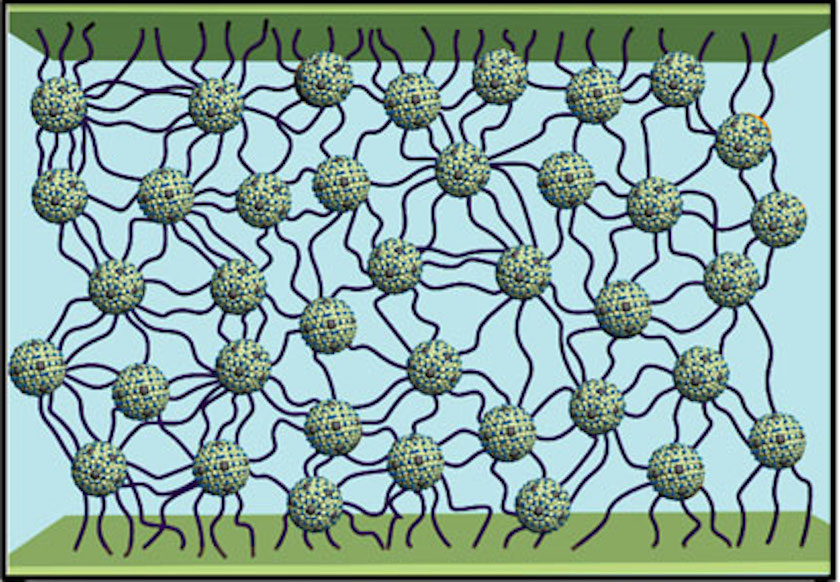

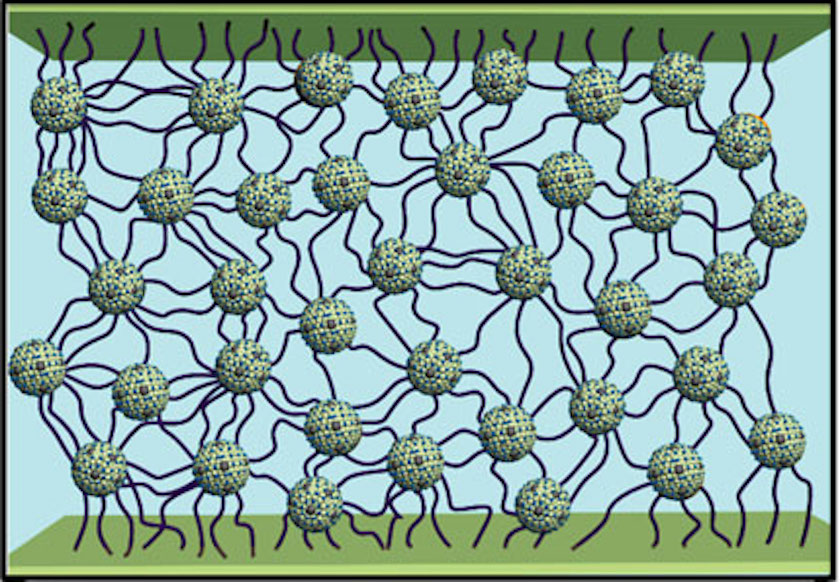

Electrochemically mediated adhesive curing (‘electrocuring’) is a concept by which adhesives can be activated on-demand when an applied voltage potential is raised above a certain threshold. As the voltage surpasses this threshold, electrochemically activated functional groups are switched ‘on’ and able to crosslink the polymer backbone and substrates that they are to be adhered to. Ideally, this crosslinking would be arrested once the voltage falls below a threshold, allowing the end-user to modify both the bonding strength and adhesive material properties. This type of control would surpass current chemical-curing adhesives.

This “on demand” adhesiveness might be able to selectively apply to a reservoir of material, similar to how light photocures 3D printing resin.

One can imagine a 3D printer constructed with this process: a reservoir of special electrocurable liquid; a movable head that applies 2V electricity to the surface to selectively fuse portions of the resin.

I’m not sure of the potential print resolution of such an approach, as it would depend how deeply the current flows into surrounding liquid. Perhaps you must have two slightly separated electrodes that dip into the liquid to apply the current.

One interesting angle would be to mix the adhesive liquid with other materials to produce various types of composite materials. In fact, this might be required to achieve different engineering properties in the prints. One can imagine a mix of resin with plastic, wood, metal or ceramic particles, much like is done with composite PLA filament today.

Could this be a future 3D printing technology? I’m not sure it could be, but I am certain it should be investigated further.

Via Nature