Researchers at the Lawrence Livermore National Laboratory have done something I’ve not seen before: mixed bio-active enzymes with 3D printing polymer.

The work was triggered by a real-life problem: new approaches to extracting oil and natural gas, such as Fracking, have the unfortunate side effect of leaking methane gas. And you might be aware that methane is a greenhouse gas far more powerful than CO2. Some say it can trap more than 100X the heat than CO2, so it’s very important to avoid these losses.

The problem is that the methane gas can easily escape into the atmosphere. If only it could be transformed into a more manageable form, like a liquid.

And this can be done! There are microscopic critters called “methanotrophs” that naturally consume gaseous methane and produce liquid methanol through natural biological processes.

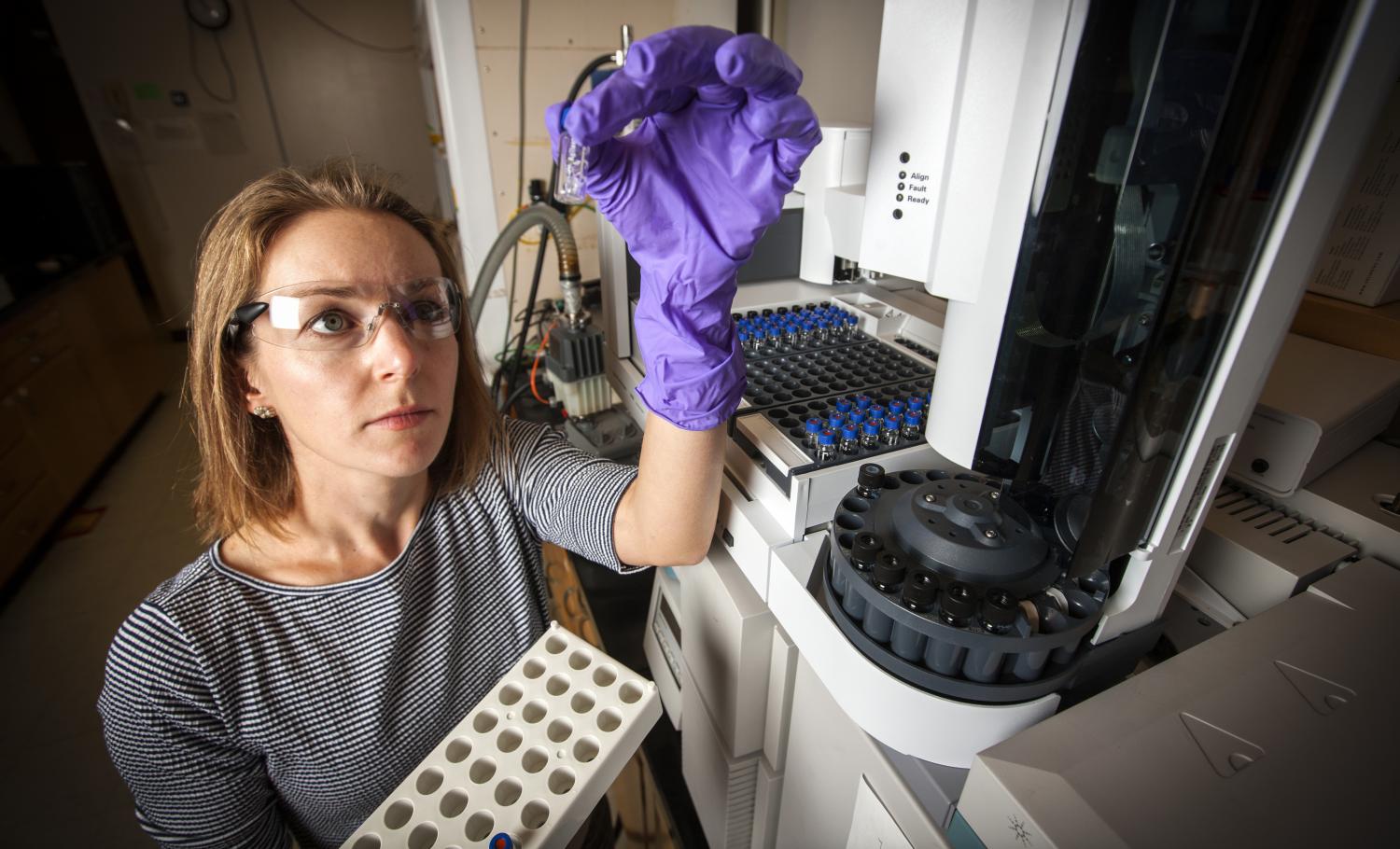

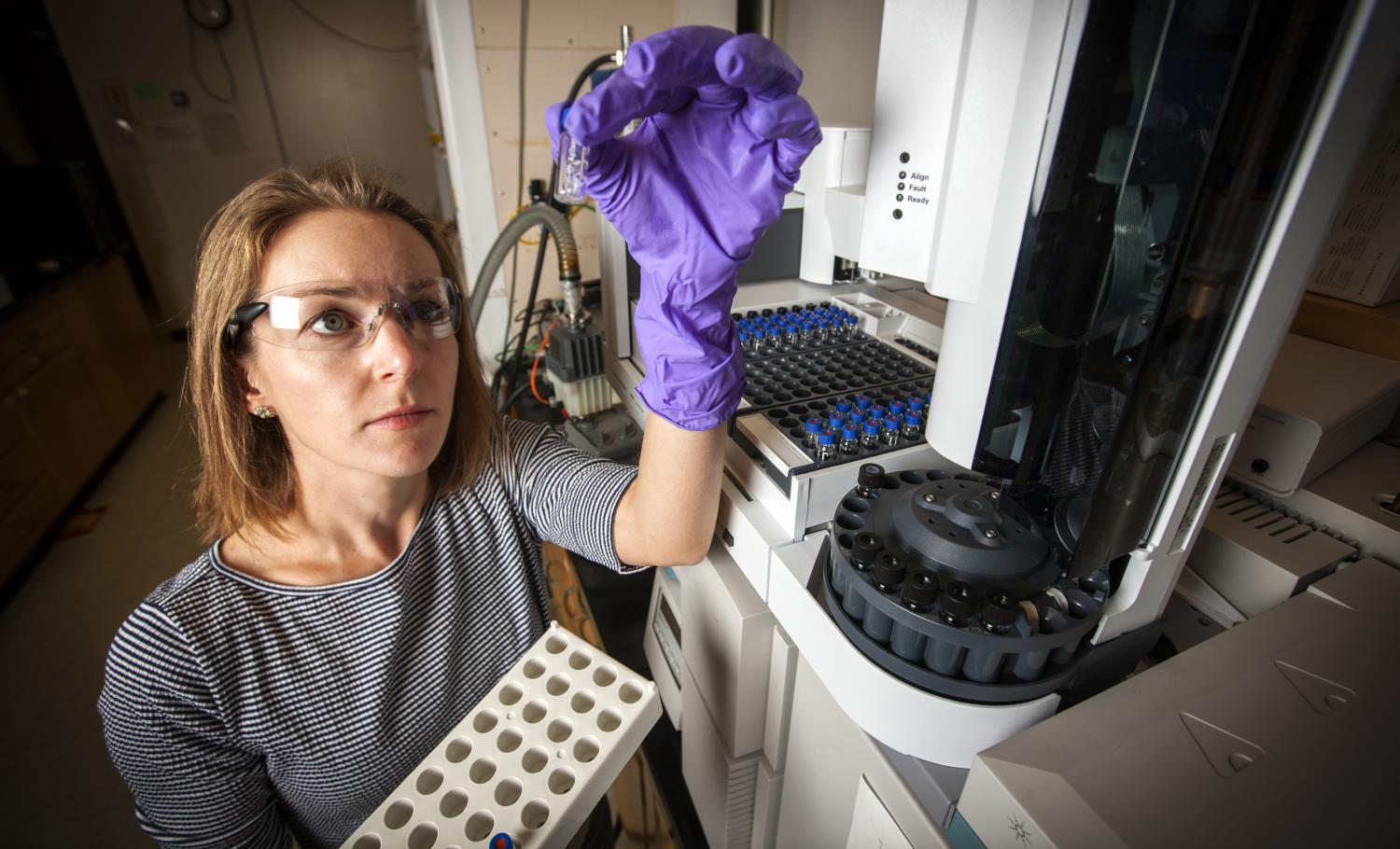

Here’s the totally amazing part of the story: the researchers broke down the bacteria and extracted a specific enzyme that performs this particular transformation. Then they mixed these enzymes with a liquid polymer suitable for stereolithography, a form of 3D printing.

And this is the miracle: the enzymes STILL FUNCTION even after being mixed in polymer!

The researchers then went on to 3D print methane reactors that would, through the use of the natural enzymes, convert gaseous methane into liquid methanol that could be handled easily.

While this experiment seems to be a success, the notion of embedding bio-active components in 3D printing material is perhaps revolutionary. Yes, we’ve all seen others infuse their 3D printer filament with copper, coffee, bamboo or algae, but this is quite different: the material ITSELF has a function.

How many opportunities does this represent? The answer could be the same number of enzymes that exist: a lot.

Via PhysOrg