Fuel3D and Cryos Technologies announced a new, custom designed 3D foot scanner using Fuel3D’s scanning tech. There are some very interesting implications of this development.

Fuel3D has been around for several years, first exhibiting a face scanner they call “Scanify”. This device is quite effective at capturing a color 3D image of human faces, and has often been used to 3D print faces, too.

But that’s a pretty narrow application of 3D scanning and printing, and over the past year Fuel3D has been developing partner applications for their 3D scanning technology. One of the first to be announced is their deal with Cryos Technologies to produce the Cryoscan3D, a specialized 3D foot scanner.

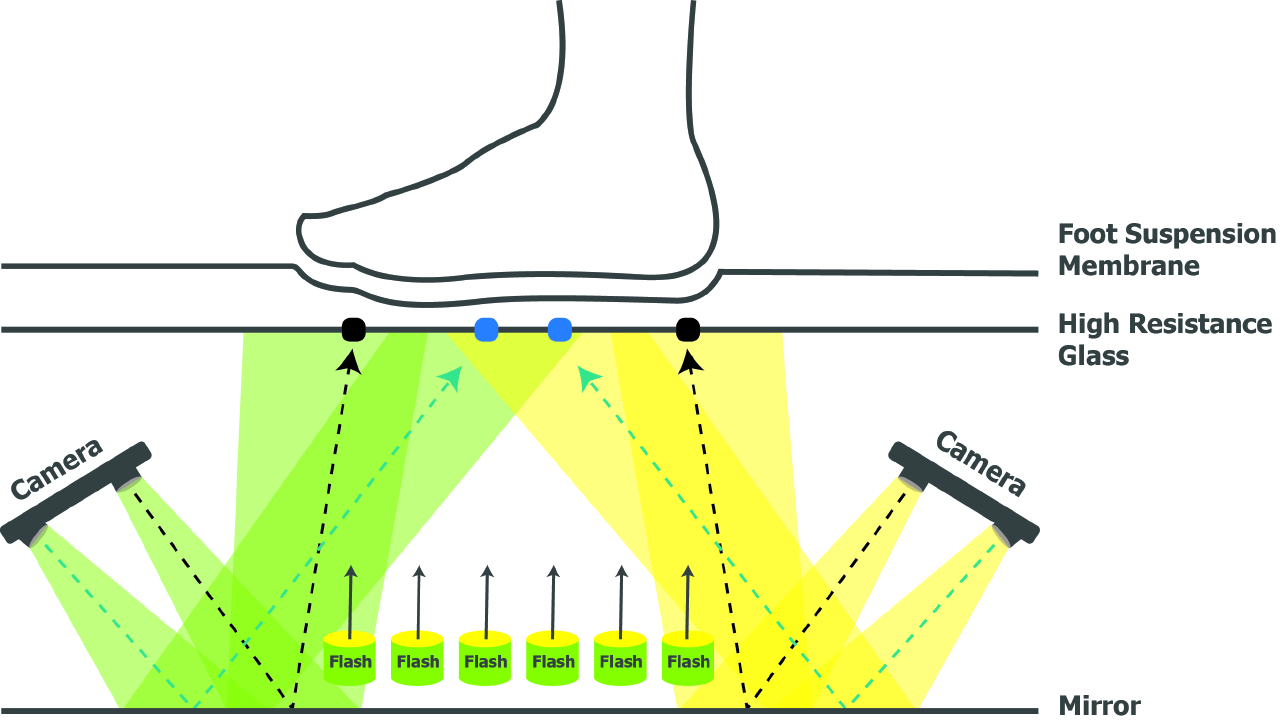

While the hardware looks like this, it’s more interesting to see how it works internally.

From the side view, the foot actually depresses slightly into a “suspension membrane”. This, I think, is a critical element, because the foot bottom otherwise would be completely flattened and 3D scans would be of far less value. Here the true 3D structure of the foot can be captured with Fuel3D’s multiple flash tech that we demonstrated some months ago.

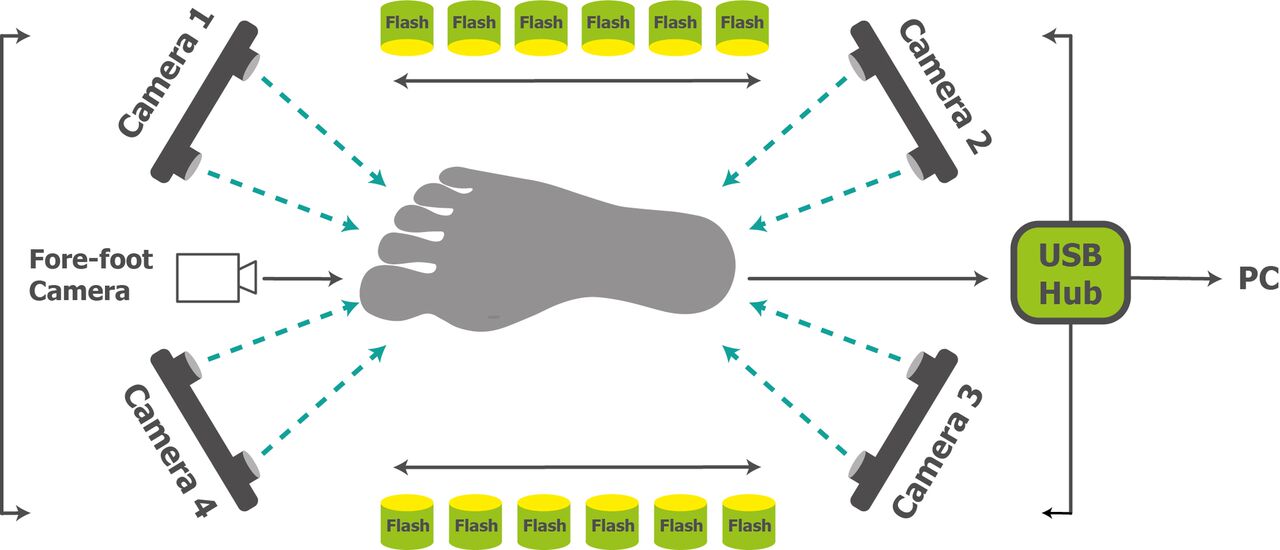

Here’s a view from the top of the Cryoscan3D, showing a very different array of cameras and flash points. These images when interpolated should easily show the detailed structure of any given foot. Cryos Technologies says the scans will be within 0.250mm of true.

Here’s the best part: the capture of these high resolution 3D foot images takes place in only 0.1 seconds!

This is where it gets interesting.

Having a device that can accurately capture anyone’s foot shape in less than a second makes it practical to operate such a scanner in professional orthotic offices worldwide. Simply take off your socks and step into the machine – scan completed instantly.

With the 3D scan captured, it’s then possible to instantly develop a custom 3D orthotic insert for the patient using modifiable templates. Presumably these can be 3D printed in nylon for use.

While it’s not likely the 3D printing would take place at the professional orthotic office, a local or regional 3D print service could quickly do so, as such prints would take only a couple of hours to complete. However, 3D print services would likely batch them together, suggesting turnaround of only a few days.

Imagine the patient experience: a quick visit to the clinic to get scanned and then receiving perfectly fit, custom 3D printed orthotics later that week. No plaster casts, no mess. Just push the button. It can only be faster if a high-speed nylon printer was in the practitioner’s office.

Maybe that will happen someday soon.

Via Fuel3D and Cryos Technologies