Research at engineering giant Siemens seems to be developing a kind of mobile 3D printing robot.

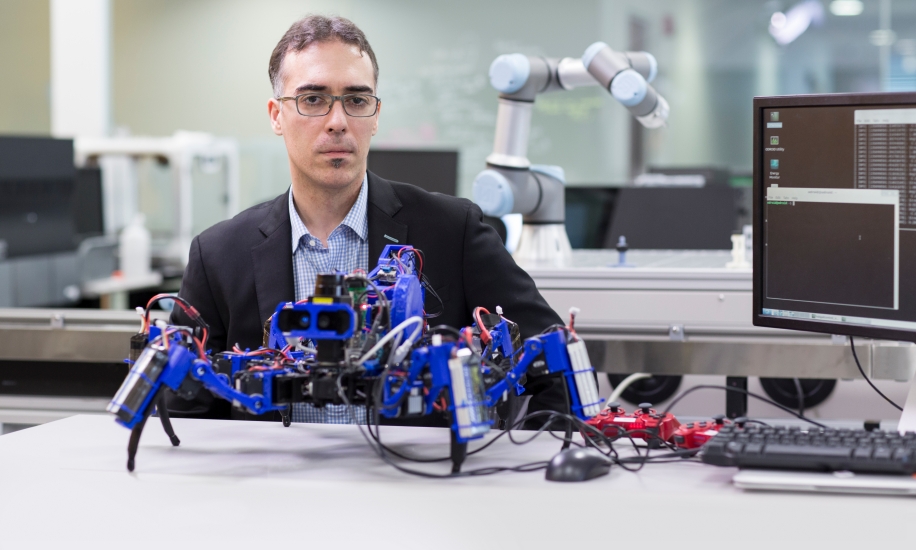

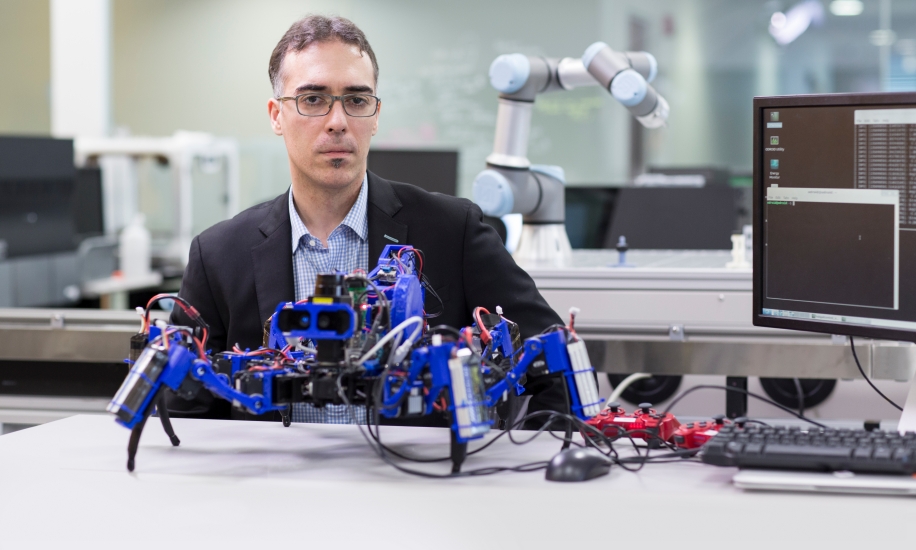

First developed in virtual reality, the robots are now being produced in real life. They’re called “Siemens Spiders”, as they include multiple legs for mobility. Each “spider” is equipped with a 3D printing “arm” as well as potentially other manufacturing tools.

This is a very big deal, and quite complex, too.

Why a big deal? To me, this is a next generation of 3D printing motion control. So far we’ve seen only a few ways to do this:

- Cartesian/delta style approaches, where a printhead is moved along three axes in a defined space in specific movements

- Robot arm approaches, where the printhead is mounted on the arm and moved about in more complex patterns

The robot arm approach was interesting because it permitted unusual movements that could overcome some of the limitations of previous movement regimes, and also could print larger volumes.

Now the Siemens Spider approach offers another key feature: unlimited movement! The spiders are essentially autonomous units that can rove around a build site with (theoretically) no boundaries on movement.

And they can work in parallel with other spiders.

If this approach can be made to work effectively, it means very large objects could be built using 3D printing techniques. Imagine, for example, an aircraft carrier hull being 3D printed, or a large multistory building – or an orbiting space station.

The development of such “spider” technology is less of a hardware problem than it is software. The 3D printing arm of a spider is essentially a problem already solved by those who have used robot arms for 3D printing. The real problem is enabling many, perhaps hundreds or even thousands, of spiders to coordinate their work on a very large project.

This will take time and experimentation to develop, as it will require spiders to be aware of each other’s presence and progress, and an ability to assign work in a manner that doesn’t overlap spiders and is still efficient.

As you can see in the images, the current generation of spiders are small enough to fit on a table, but I can imagine future generations becoming more specialized. Imagine a much larger spider that’s used to create huge bulky structures efficiently, for example. Or perhaps very tiny spiders that may add detailed features where the large bots can’t go, or to apply different types of materials or install smaller components.

Someday it may be possible to see an entire large structure built (but not designed) by spidery robots. The design, that will have to stay with us humans for a while.

Via Siemens