If you’re like me and 3D print a lot, you may find your work area piling up with empty filament spools. My advice: Keep Them!

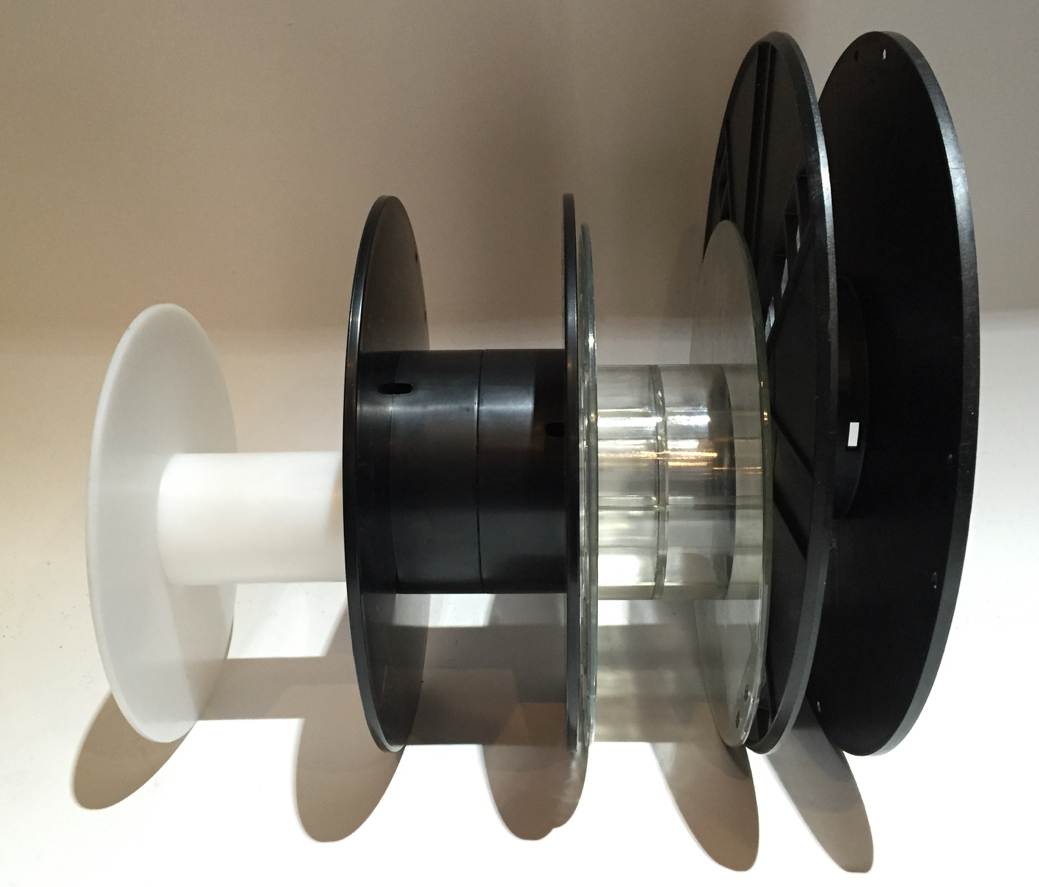

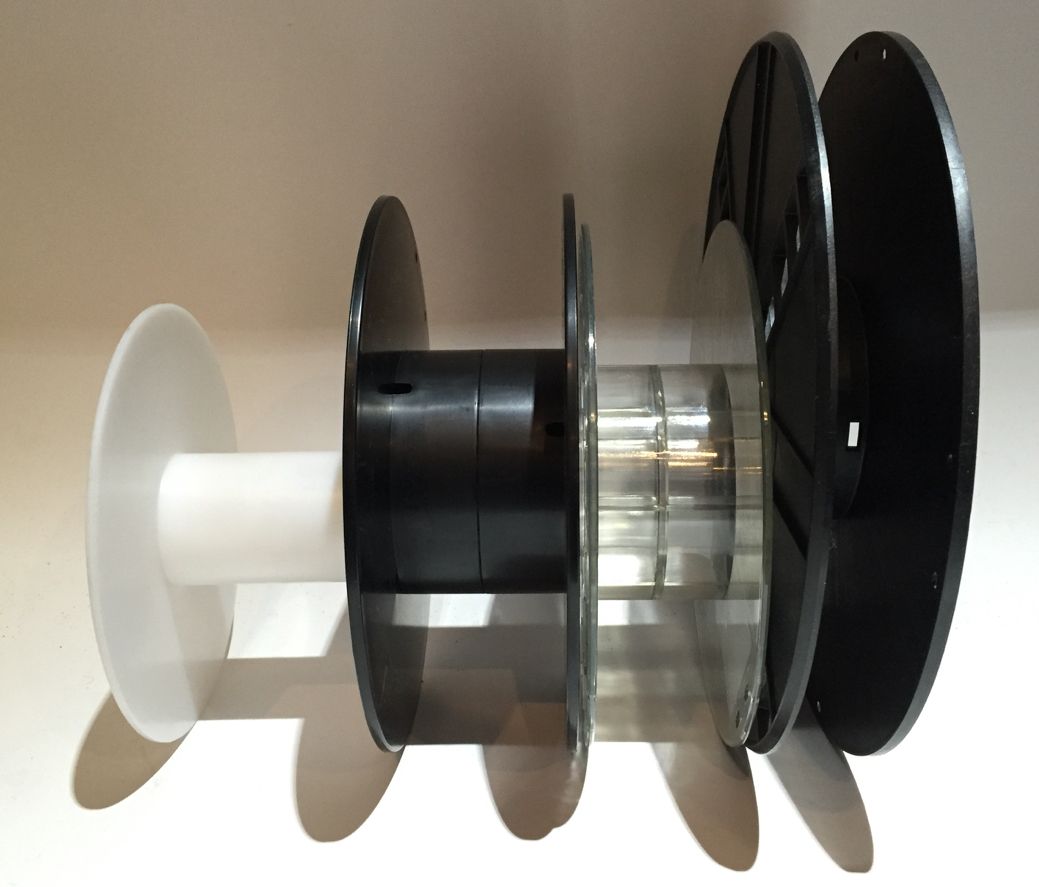

Well, actually don’t keep ALL of them; instead keep at least one of each style you encounter. There’s a very good reason for this.

The empty spools can be used to resolve printing difficulties. Imagine the following scenario:

You’re about to begin a print for a larger object, and suddenly become aware that the spool with the color you’re going to print with may – or may not – have sufficient filament to last for the entire print.

Sometimes you can “eyeball” the spool and determine that it either clearly does not have sufficient material, or that it definitely does (as in the case of a fresh spool).

But there are many cases where the eyeball test doesn’t come up with a definitive answer. Is it close? Should I risk starting the print? What if I end up wasting the remaining plastic on the spool?

The answer, at least for me is to use the following procedure:

- Weigh the spool with the remaining questionable amount of filament.

- Weigh an empty spool of the same format (see, this is why you keep them!)

- Subtract the weight of the empty from the partially full spool. Now you know EXACTLY how much filament remains on the spool.

- Slice your 3D model and take note of the estimated weight of plastic required – and curses to slicers that display only “meters” of filament, which is useless for this procedure.

- If the spool offers well over the required amount, you’re good to go. Otherwise, get a fresh spool.

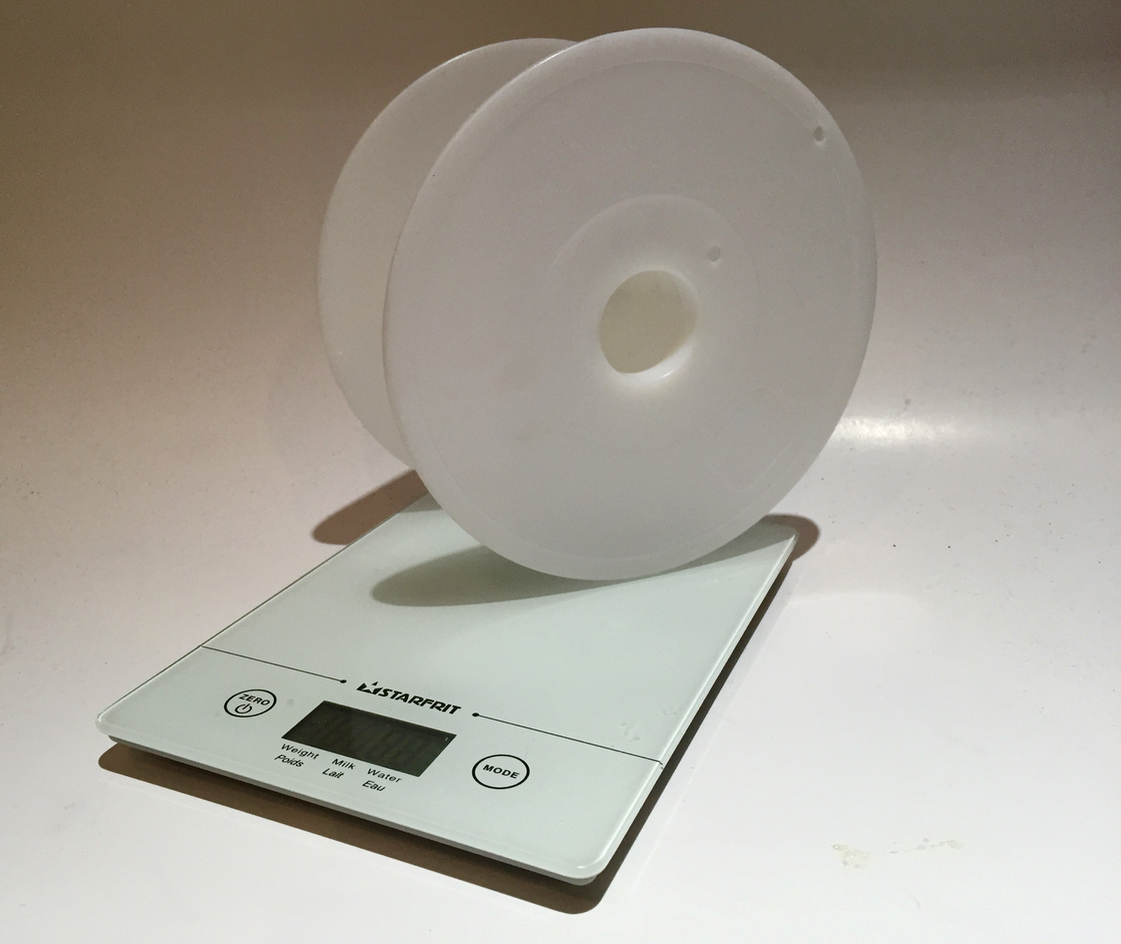

The procedure requires a small digital table scale like this one. They’re very inexpensive and essential for any 3D print operator.

Keep some empties handy and get yourself a digital scale. It will pay for itself the first time you don’t fail a print due to a filament shortage.