ZMorph has been producing a machine with multiple methods of fabrication, but now they’ve stepped it up a level with their ZMorph 2 SX machine.

Yes, the 2 SX does all the same things their previous model performed: CNC Milling, Laser Etching, paste extrusion and, of course, plastic 3D Printing, but the new machine packages it all in a far nicer manner, making the 2 SX much easier to use.

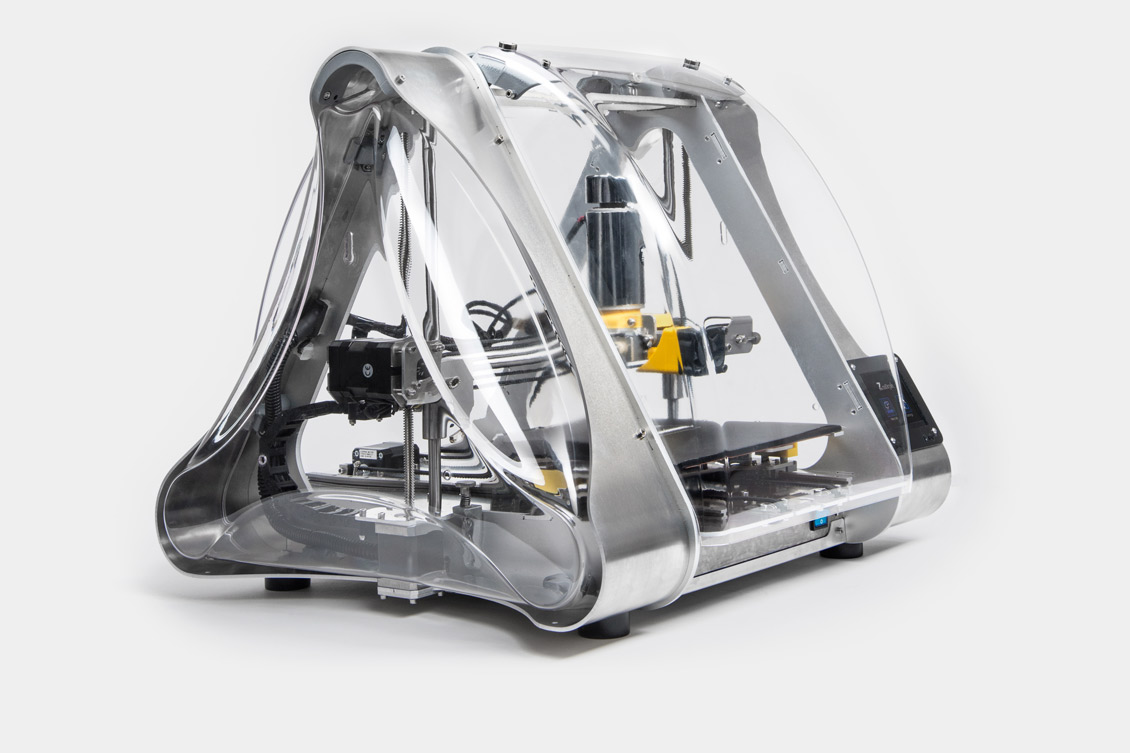

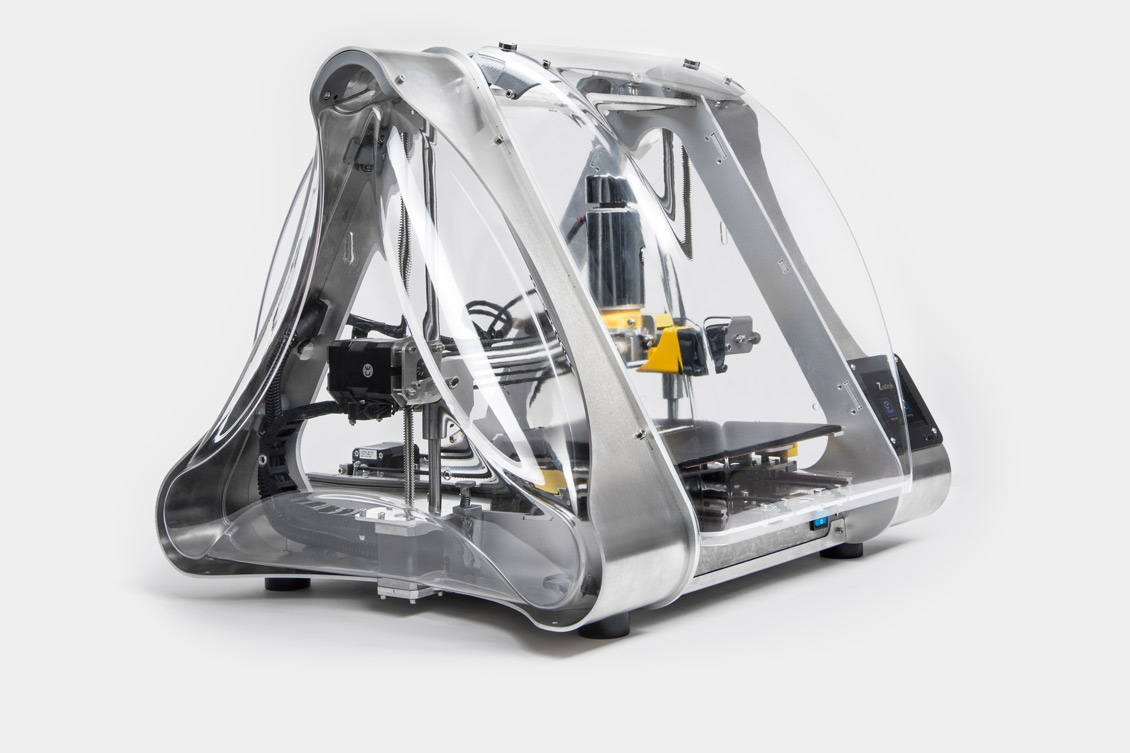

And also to look at: the 2 SX is perhaps the wildest looking 3D printing device I’ve seen. It’s not a white box with shiny front door, no, this item has wild triangular features that emphasize the power of this desktop machine. These removable transparent covers also provide a means to capture heat (and dust) within the working volume, so they’re functional as well as stylish.

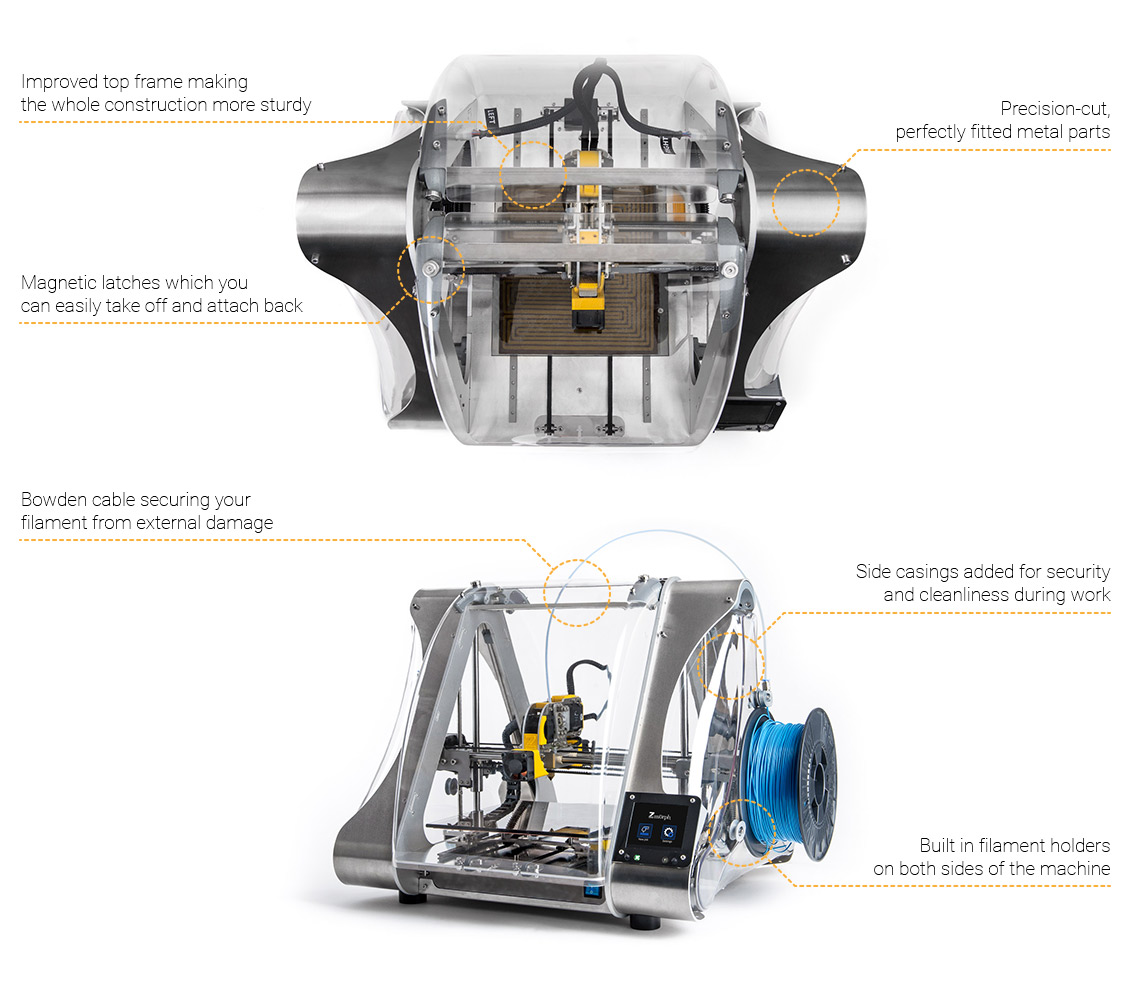

So what’s new? First, they’ve re-engineered the “switching system” that changes the function of the machine between its three operating modes. The new system uses magnets to enable very rapid switches, as seen here.

The 3D printing function has been improved to permit the use of far more materials, partly due to the enclosed print volume and heated print surface, but also because of improvements to the extruder, which now permits flexible filaments.

There’s also a handy color touchscreen for operations, which is now becoming a mandatory feature on any desktop 3D printer.

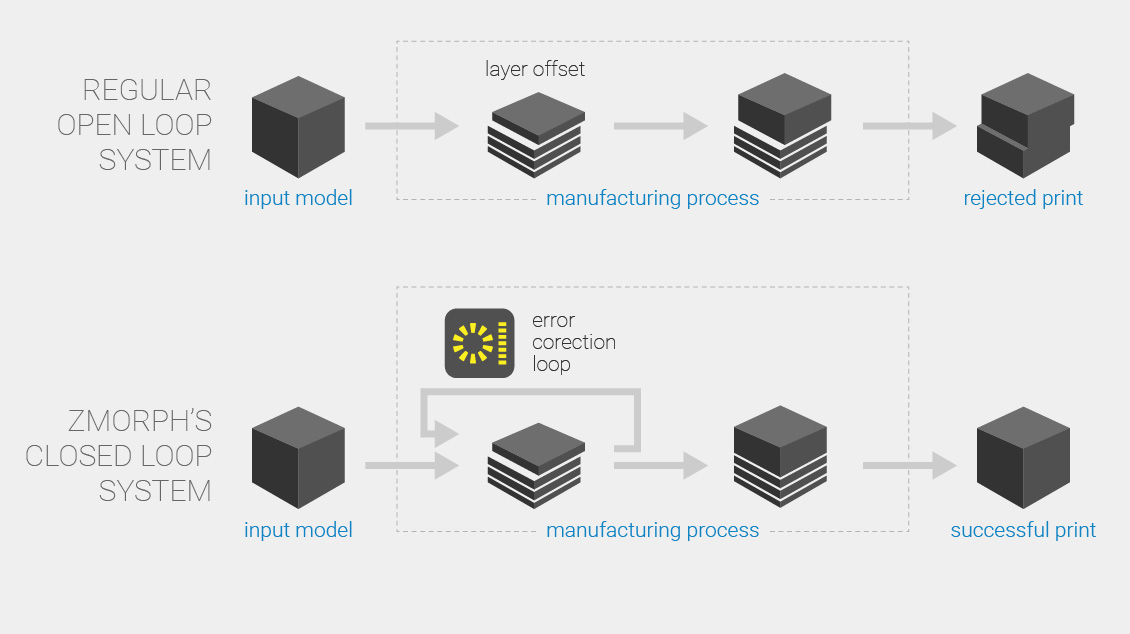

One interesting feature that I can’t find a proper technical description for is their “Closed Loop System”, which they describe as follows:

Introducing ZMorph’s unique Closed Loop System. The system works like a guard – it monitors the printer and maintains precision at all times, especially when printing at high speeds, or CNC milling with high torque. It’s reliability reimagined.

Yes, but how does it work? There’s a graphic, but this doesn’t really help me. More info needed here, obviously.

And there’s a twelve month warranty, which is quite important on a machine like this that involves many moving parts.

The 2 SX is available in two trim levels: a “basic set” model for USD$2,690 and a “full set” model for USD$3,890. The difference is simply that the basic machine includes only 3D printing and CNC milling features. If you want the laser and paste extruder, you’ll select the full set model.

Finally, there is the question, “do you need all these functions?”

The answer is in an example project made by ZMorph:

It’s an incredible gift package made using three of the functions: CNC milling to make the wood box; 3D printing to make the gifts inside and the flexible wrapper belt, and finally the laser etcher to label the box. Incredible!

Who wouldn’t want to make stuff like that?

Via ZMorph