YouTuber Tinkernut shows how to produce a “cheap 3D printer” in a recent video, but there’s an ironic twist to the plan.

One of the key objectives of anyone making their own 3D printer is to reduce cost, and that’s definitely the case here, where Tinkernut somehow builds a working 3D printer for USD$65.

That’s cheap!

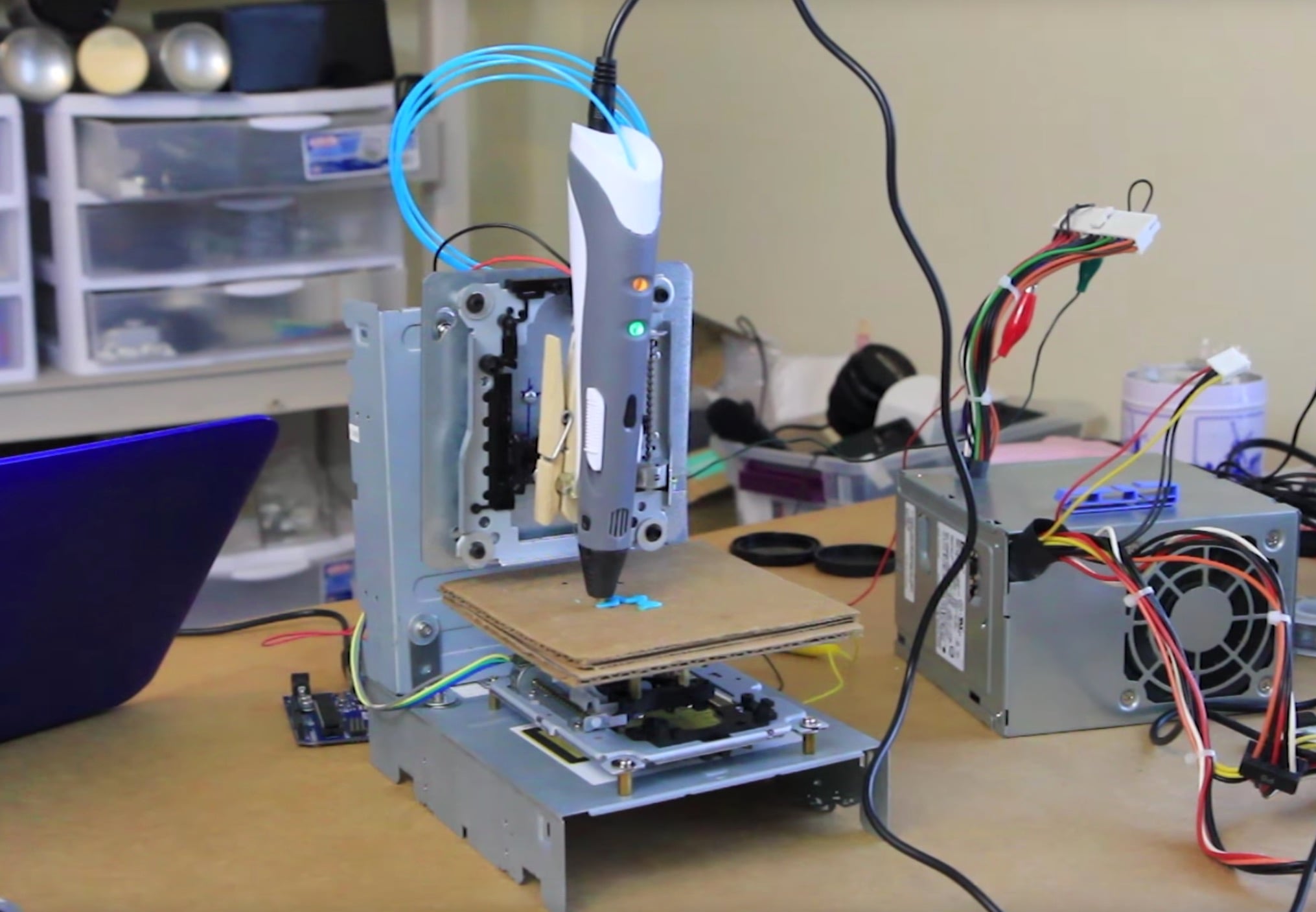

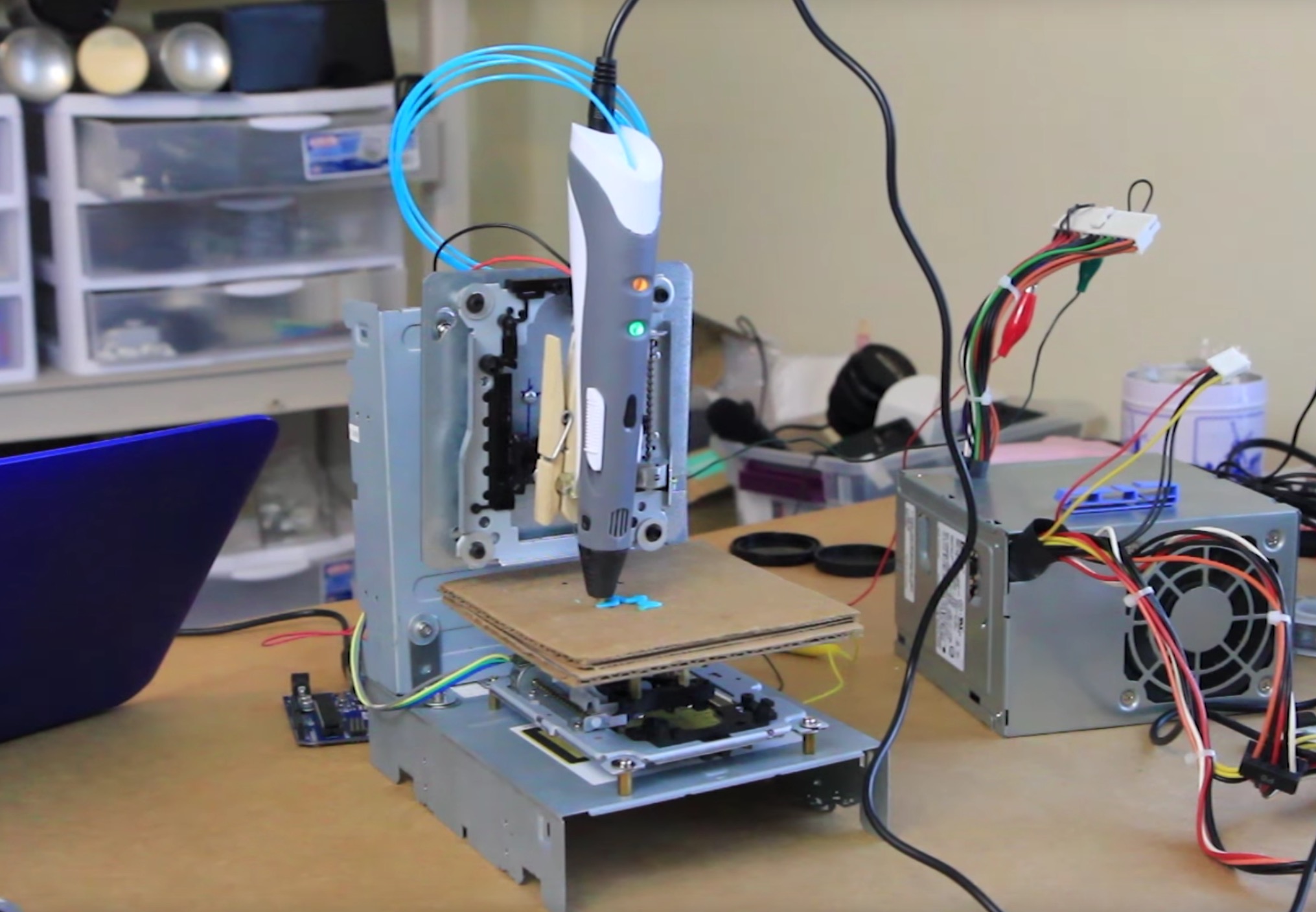

But the process involves a bit of a cheat. Basically, the design involves reusing a cartesian motion platform previously designed by Tinkernut, costing USD$20, and combining that with a modified 3D pen.

A 3D pen? You remember, those handheld devices that include an extruder and hot end, and hopefully some safety features to keep you from burning your fingers and home. You gently move them around in 3D space to “print” 3D things. My opinion is that these devices are not really 3D printers by any definition. They are a hand tool used manually to make stuff, like a hammer or saw.

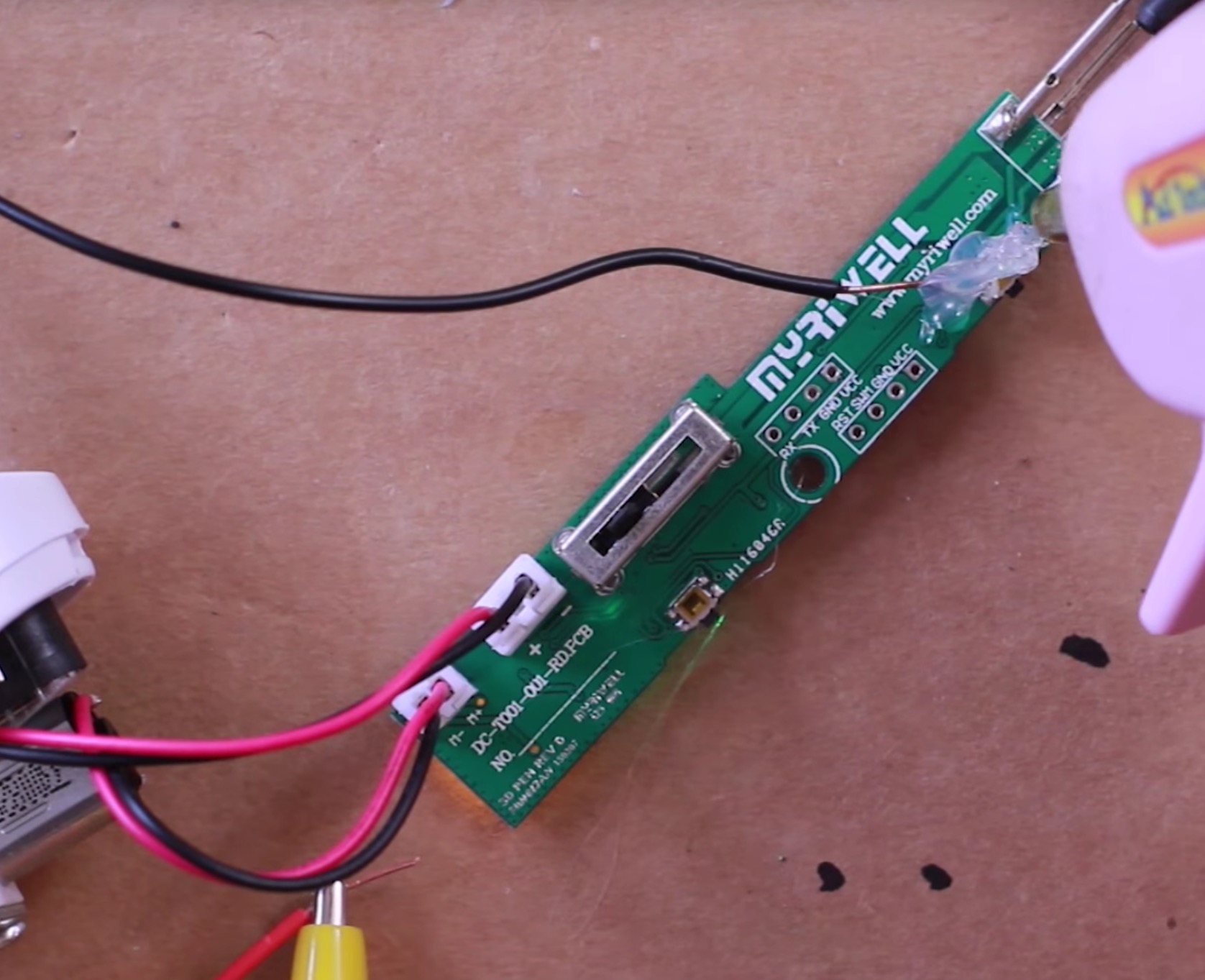

However, if you take them apart, they do include a rudimentary hot end and a motor to push plastic filament through it. Those are just the things you’d need to add to the motion platform to make a real 3D printer.

In the video here, you’ll see how the pen is essentially used as-is, with a simple modification to trigger it remotely from an arduino board controlling the cheap 3D printer:

I think this project is certainly interesting and would be fun for someone to start 3D printing, but certainly not able to print anything serious. The reliability, resolution, print volume, plastic handling and speed are severely limited on this concept device.

However, there is a bit of irony in this project: when desktop 3D printers first emerged, many were unable to afford them, as the costs were then well over USD$1,000 to buy anything usable. Partly a reaction to that was the development of these 3D pens, which, in a sense, allowed one to get in on the 3D printing movement at low cost.

One of the companies producing pens, 3Doodler, capitalized on this big time in 2013, when they launched their first pen product. It sold to over 26,000 buyers who pledged USD$2.3M!

Now we see this same 3D pen concept being used to make a working 3D printer. Things get around.